Method and device capable of remarkably improving shock resistance of aviation aluminium alloy material

An aluminum alloy material, a remarkable technology, applied in the field of laser processing and material surface strengthening, can solve the problems of not finding the anti-vibration performance of aviation aluminum alloy materials, unable to improve the service life or noise reduction effect, and improve the vibration damping of materials, so as to improve the Service life and noise reduction effect, easy to intelligent control, improve the effect of vibration damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

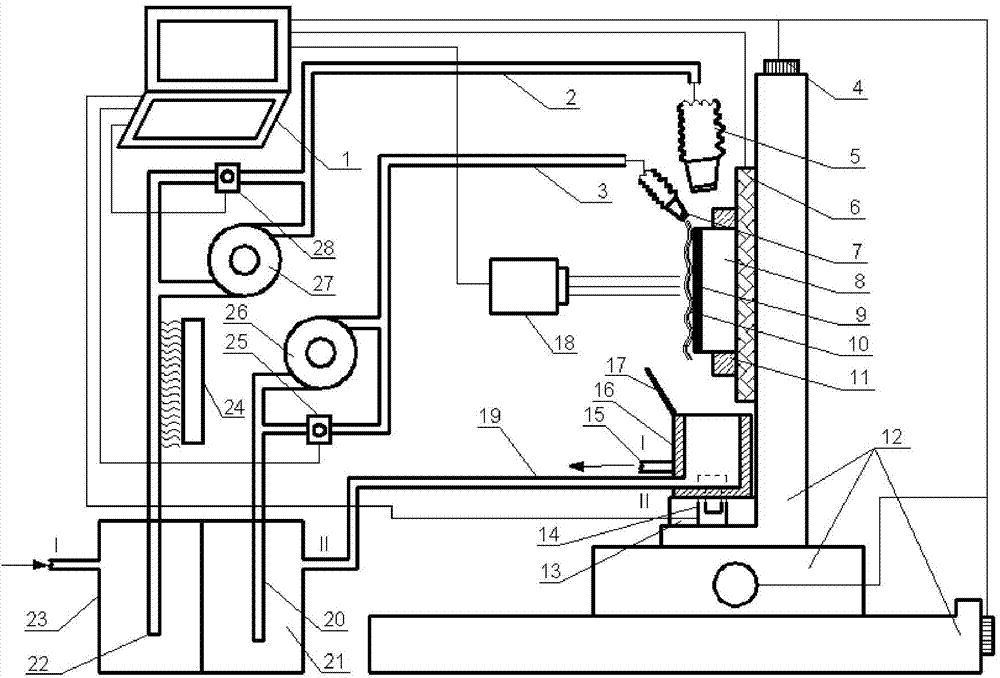

[0032] Such as Figure 1-4 shown.

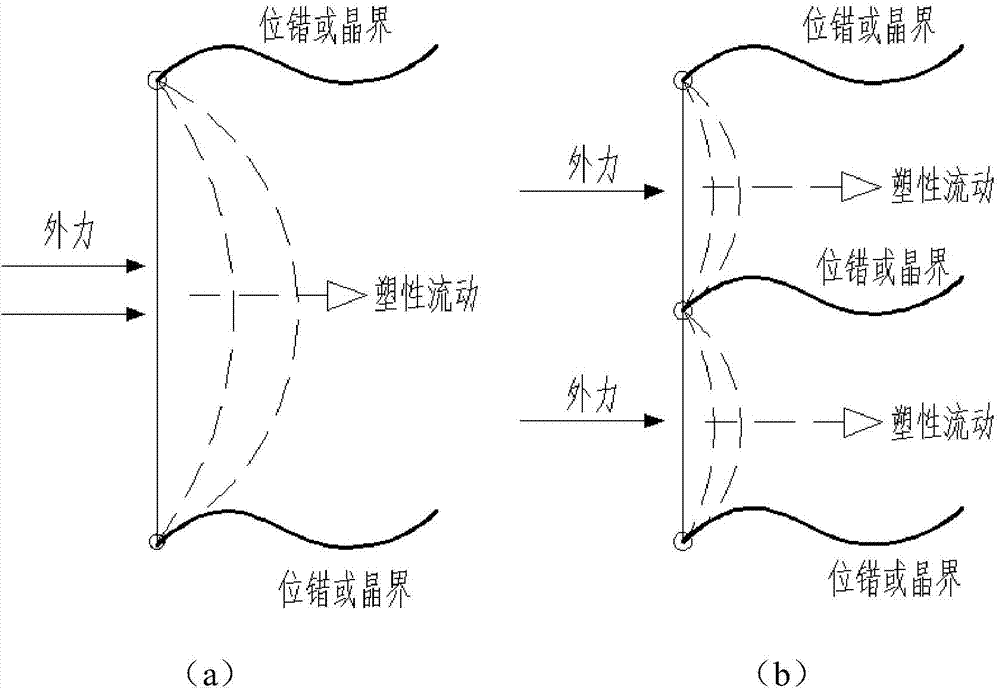

[0033] The following takes 6061-T6 aviation aluminum alloy as an example to further explain the non-structural improvement method to improve its anti-vibration performance. The principle is as follows image 3 As shown, the specific steps include:

[0034] A) First inject the prepared aqueous solution for cooling and silicon oil for restraint into the water tank 23 and the oil tank 21 respectively, and start the cold air device 24 to pre-cool the aqueous solution to 5-8°C. The aqueous solution is preferably made of water, water-based rust inhibitor and The mixed solution prepared by silicone oil cleaning agent is configured according to the strict volume ratio of 1:0.01:0.05. This aqueous solution can realize cooling while avoiding oxidation of the aluminum alloy surface, and at the same time can clean the residual silicone oil on the surface of the workpiece after shot peening.

[0035] B) Fix the 6061-T6 workpiece 8 coated with high-temp...

Embodiment 2

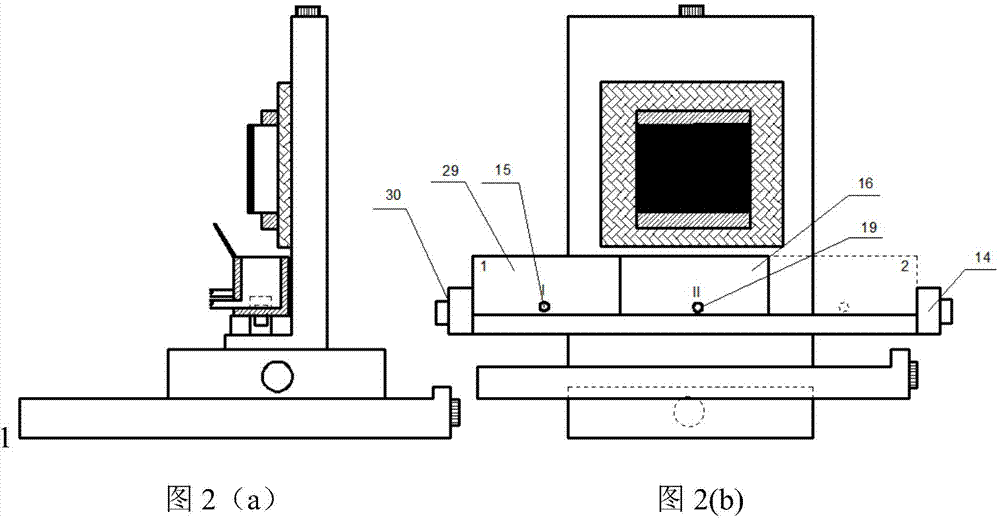

[0041] Such as Figure 1-2 shown.

[0042] A device that can significantly improve the anti-vibration performance of aviation aluminum alloy materials, such as figure 1 and figure 2 As shown: an electromagnetic transposition device is installed on the horizontal position of the vertical motion table 12. The electromagnetic transposition device includes a guide rail 13, a solenoid valve I 14 and a solenoid valve II 30, and an iron collection box that can move horizontally is installed on the guide rail 13. The middle of the collection box is divided into two chambers by a metal plate—the water storage chamber 29 and the oil storage chamber 16, such as figure 2 As shown, the bottoms of the two chambers are processed with outlets I and II respectively connected to the inlets of the water tank 23 and the oil tank 21 through the water guide pipe 15 and the oil guide pipe 19. The inlet of water pump 27 and oil pump 26 connects water tank 23 and oil tank 21 by water inlet pipe 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| damping factor | aaaaa | aaaaa |

| damping factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com