Polyethylene terephthalate (PET)/polycarbonate (PC) alloy material as well as preparation method and application thereof

A technology of alloy material and toughening agent, which is applied in the field of PET/PC alloy material and its preparation, can solve the problems of performance difference, affecting the performance and application of the blend system, and achieve the effect of excellent vibration reduction and easy processing and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

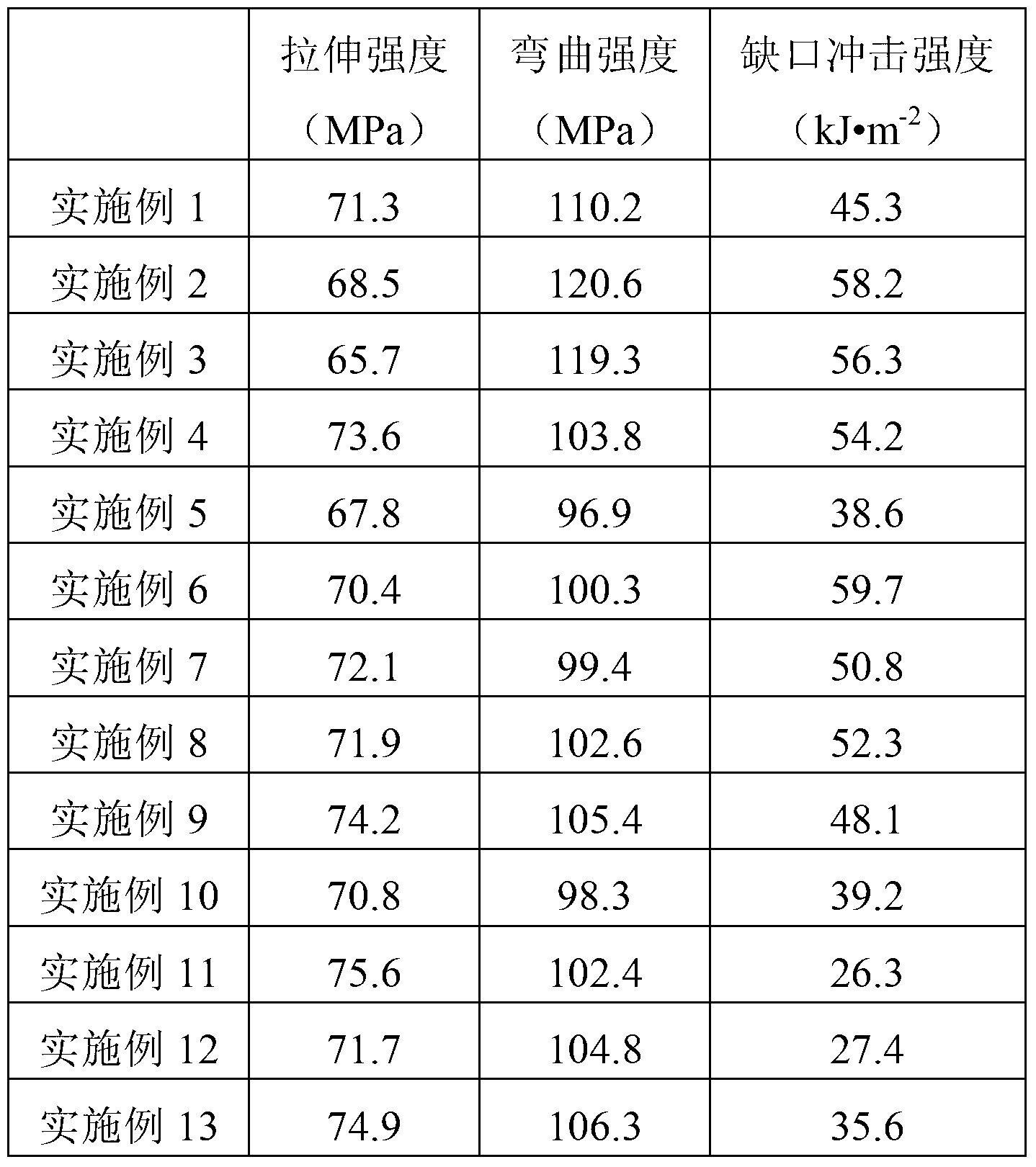

Examples

Embodiment 1

[0036] Embodiment 1: the preparation of PET / PC alloy material

[0037] After PET and toughening agent ACR are blended in the first stage of the screw extruder, they are blended with other components in the second stage, extruded and granulated (270°C), and PET / PC alloy material is obtained.

[0038] Among them, PET (Yuanfang Industry (Shanghai) Co., Ltd., intrinsic viscosity is 1.0dl / g) 40 parts by weight, PC (Bayer, Germany, intrinsic viscosity is 1.2dl / g) 60 parts by weight, ACR (Rohm and Haas, USA) company) 10 parts by weight, compatibilizer EMA (ExxonMobil, USA) 10 parts by weight, carbon black (Anyang Delong Chemical Co., Ltd.) 2 parts by weight, benzotriazole compounds (Ciba, uv- 326) 1 part by weight, hindered phenol and phosphite compound (Ciba, 168) 1 part by weight.

Embodiment 2

[0039] Embodiment 2: the preparation of PET / PC alloy material

[0040] After blending all components, extrude and granulate (280°C) in a screw extruder to obtain a PET / PC alloy material.

[0041] Among them, 15 parts by weight of PET (Yuanfang Industry (Shanghai) Co., Ltd., with an intrinsic viscosity of 1.5dl / g), 85 parts by weight of PC (Bayer, Germany, with an intrinsic viscosity of 1.3dl / g), toughener MBS (American Luo Menhas Company) 20 parts by weight, compatibilizer E-MA-GMA (Guangzhou Hecheng Chemical) 15 parts by weight, carbon black (Anyang Delong Chemical Co., Ltd.) 3 parts by weight, benzotriazole compounds (gas Ciba Company, uv-326) 1 part by weight, hindered phenol and phosphite compound (Ciba Company, 168) 1 part by weight.

Embodiment 3

[0042] Embodiment 3: the preparation of PET / PC alloy material

[0043] After blending all the components, extrude and granulate (260°C) in a screw extruder to obtain a PET / PC alloy material.

[0044] Among them, 5 parts by weight of PET (Yuanfang Industry (Shanghai) Co., Ltd., with an intrinsic viscosity of 1.5dl / g), 85 parts by weight of PC (Bayer, Germany, with an intrinsic viscosity of 1.3dl / g), toughening agent SEBS (American Science and Technology Co., Ltd. Teng Polymer Co., Ltd.) 30 parts by weight, compatibilizer POE-g-MAH (Ju Sailong Engineering Plastics Co., Ltd.) 20 parts by weight, carbon black (Anyang Delong Chemical Co., Ltd.) 2 parts by weight, benzotriazole 1 part by weight of compound (Ciba, uv-326), 1 part by weight of hindered phenol and phosphite compound (Ciba, 168).

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com