Preparation method of graphene nanoribbons

A technology of graphene nanobelts and carbon nanowalls, applied in the field of synthesis of nanocarbon materials, can solve the problem of low electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Such as figure 1 As shown, a method for preparing graphene nanoribbons according to an embodiment includes the following steps:

[0025] Step S110: Place the metal substrate in an acid solution with a concentration of 0.01 mol / L to 1 mol / L and etch for 0.5 minutes to 10 minutes; under oxygen-free conditions, heat the etched metal substrate to 600°C to 900°C , Use ultraviolet light to irradiate the surface of the metal substrate, and pass in carbon-containing gas and protective gas for 30 minutes to 300 minutes. After the reaction, carbon nano-walls are obtained on the surface of the metal substrate; where the flow of carbon-containing gas It is 10 sccm (ml per minute in standard state) ~ 1000 sccm, and the flow ratio of carbon-containing gas to shielding gas is 2 to 10:1. After the reaction is completed, the introduction of carbon-containing gas is stopped, heating and ultraviolet light irradiation are stopped, and after cooling to room temperature, carbon nanowalls are ob...

Embodiment 1

[0048] The preparation of the graphene nanoribbons of this embodiment is as follows:

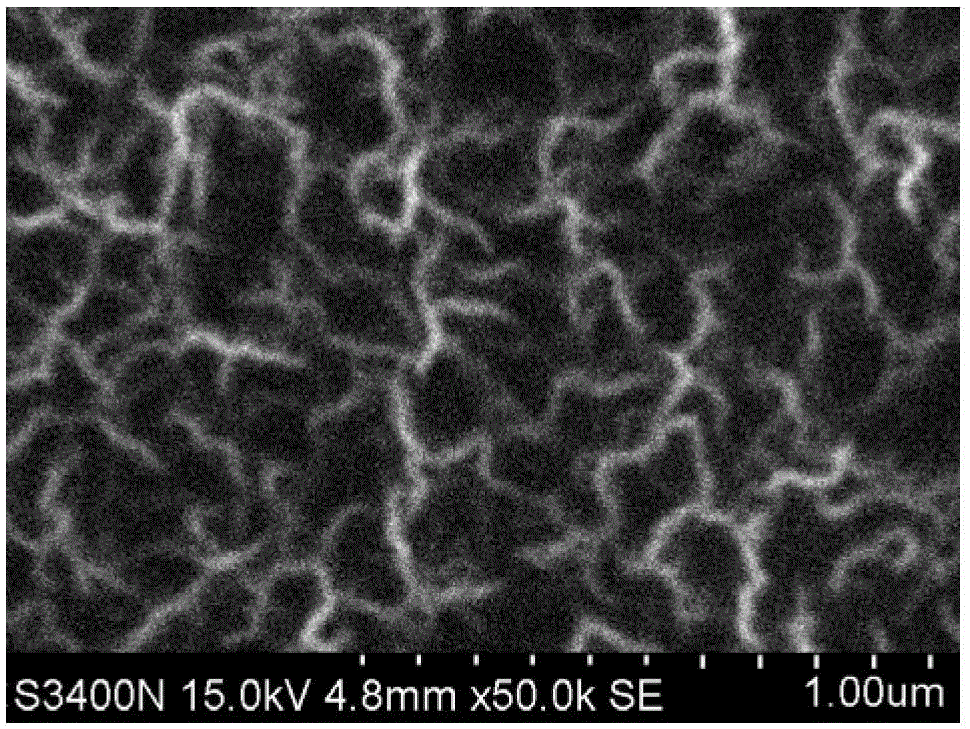

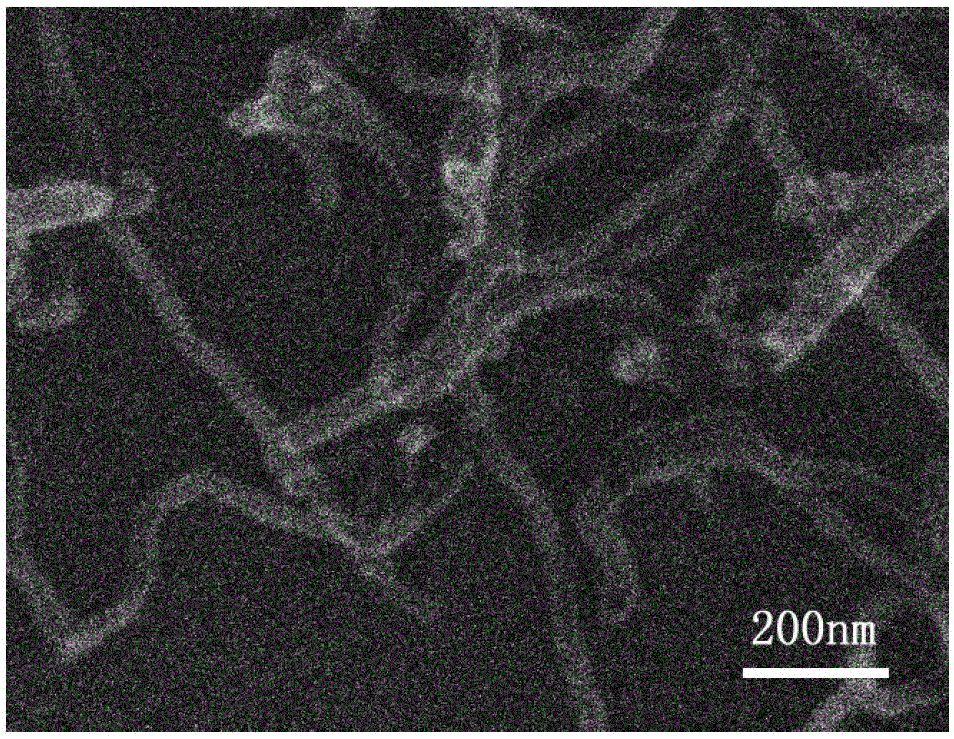

[0049] (1) Preparation of carbon nanowall: (a) Put the nickel foil in a hydrochloric acid solution with a concentration of 1 mol / L and etch for 0.5 minutes. After etching, wash with deionized water, ethanol, and acetone in sequence; (b) Wash After putting the nickel foil into the reaction chamber and venting the air in the reaction chamber, heat the nickel foil to 900°C, then turn on the ultraviolet light source device to irradiate the surface of the nickel foil with ultraviolet light, and then pass in methane and nitrogen to maintain For 100 minutes, the flow of methane steam is 200sccm, and the flow ratio of methane steam to nitrogen is 2:1. After the reaction is completed, stop the methane steam, stop heating the nickel foil, and turn off the light source equipment. Wait for the reaction chamber After cooling to room temperature, the introduction of nitrogen gas was stopped, and the carbon n...

Embodiment 2

[0055] The preparation of the graphene nanoribbons of this embodiment is as follows:

[0056] (1) Preparation of carbon nanowall: (a) Put the iron foil into a sulfuric acid solution with a concentration of 0.5 mol / L and etch for 4 minutes. After etching, use deionized water, ethanol, and acetone to clean; (b) Put the cleaned iron foil into the reaction chamber and remove the air in the reaction chamber, heat the iron foil to 600°C, then turn on the ultraviolet light source equipment to irradiate the surface of the iron foil with ultraviolet light, and then pass in ethane vapor And argon, keep for 200 minutes, where the flow rate of ethane vapor is 100sccm, and the flow ratio of ethane vapor to argon is 5:1. After the reaction is completed, stop feeding ethane vapor and stop heating the iron foil , And turn off the light source equipment. After the reaction chamber is cooled to room temperature, stop passing argon gas to obtain the carbon nano wall of this embodiment on the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com