Method for reusing sintered reclaimed NdFeB material

A neodymium-iron-boron and recycled material technology, applied in magnetic materials, magnetic objects, electrical components, etc., can solve the problems of complex process flow, large amount of rare earth, power consumption, etc., achieve simple process flow, reduce sintering temperature, and improve consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

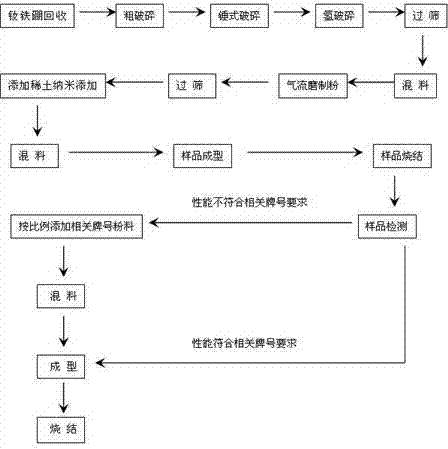

Method used

Image

Examples

Embodiment 1

[0023] Example 1: N38

[0024] First, the metal block Pr or Pr-Nd is processed into nano-sized powder with an average particle size of 40-60nm by the rapid-in-situ packaging rare earth nano powder arc method.

[0025] The NdFeB recycled material is roughly crushed into large blocks of 20-40mm with a jaw crusher, and then the large particles are further crushed into small particles with a particle size of less than 10mm with a hammer crusher.

[0026] The powder is heated to 550-650℃ for dehydrogenation for 6-7 hours after absorbing hydrogen at room temperature in the reactor of the hydrogen crushing furnace for 2 to 4 hours to prepare coarse particles with a particle size of 60 to 80 mesh and screen the material with a 10 mesh vibrating screen. Then add 1~5‰ of antioxidant (polyethylene oxide alkyl ether) and mix evenly for 10~30 minutes.

[0027] The waste powder after hydrogen crushing and mixing is ground by QLM-400 jet mill at 0.8MPa working pressure to fine powder with an averag...

Embodiment 2

[0030] Example 2: N40

[0031] First, the metal block Pr or Pr-Nd is processed into nano-sized powder with an average particle size of 40-60nm by the rapid-in-situ packaging rare earth nano powder arc method.

[0032] The NdFeB recycled material is roughly crushed into large blocks of 20-40mm with a jaw crusher, and then the large particles are further crushed into small particles with a particle size of less than 10mm with a hammer crusher.

[0033] The powder is heated to 550-650℃ for dehydrogenation for 6-7 hours after absorbing hydrogen at room temperature in the reactor of the hydrogen crushing furnace for 2 to 4 hours to prepare coarse particles with a particle size of 60 to 80 mesh and screen the material with a 10 mesh vibrating screen. Then add 1~5‰ of antioxidant (polyethylene oxide monofatty acid ester) and mix uniformly for 10~30 minutes.

[0034] The waste powder after hydrogen crushing and mixing is ground by QLM-400 jet mill at 0.8MPa working pressure to fine powder wi...

Embodiment 3

[0037] Example 3: N42

[0038] The difference from Example 2 is that: the existing 048001 (NdFeB380 / 80) brand conventional powder and the need to prepare 048002 (NdFeB350 / 96) brand products, the recycled powder and conventional powder (048001 brand) in a 4:6 ratio Mix evenly in the mixer for 2 to 4 hours. After fully mixing, perform batch magnetic field orientation molding, isostatic pressing, and vacuum sintering. Product performance test data is: Br: 1.32~1.36T, Hcb: 971~1003kA / m, Hcj: 1020~1066kA / m, (BH)max: 338~358kJ / m 3 According to GB / T13560-2009, it is judged that its performance meets the performance requirements of 048002 (NdFeB350 / 96). This batch of recycled materials can be used for mass production of 048002 (NdFeB350 / 96) products; the antioxidant is polyethylene oxide allyl Base ether. Others are the same as in Embodiment 2, so they are omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com