Modified lithium ion battery graphite negative material and preparation method thereof

A technology of lithium ion battery and graphite negative electrode, which is applied in the field of electrochemical materials and new energy, can solve the problems of difficulty in uniformly covering graphite negative electrode material, easy agglomeration, and high activity of nano-scale silicon powder, and achieves easy realization and simple process. , the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Weigh butyl titanate, silicon powder and graphite according to the molar ratio Ti:Si:C=3:0.8:500. The ball milling mixing treatment was carried out under the protection of nitrogen with the absolute ethanol solution of CMC with a mass percent content of 0.5% as the dispersant. The obtained mixed slurry was vacuum-dried at 80° C. to obtain a dried material.

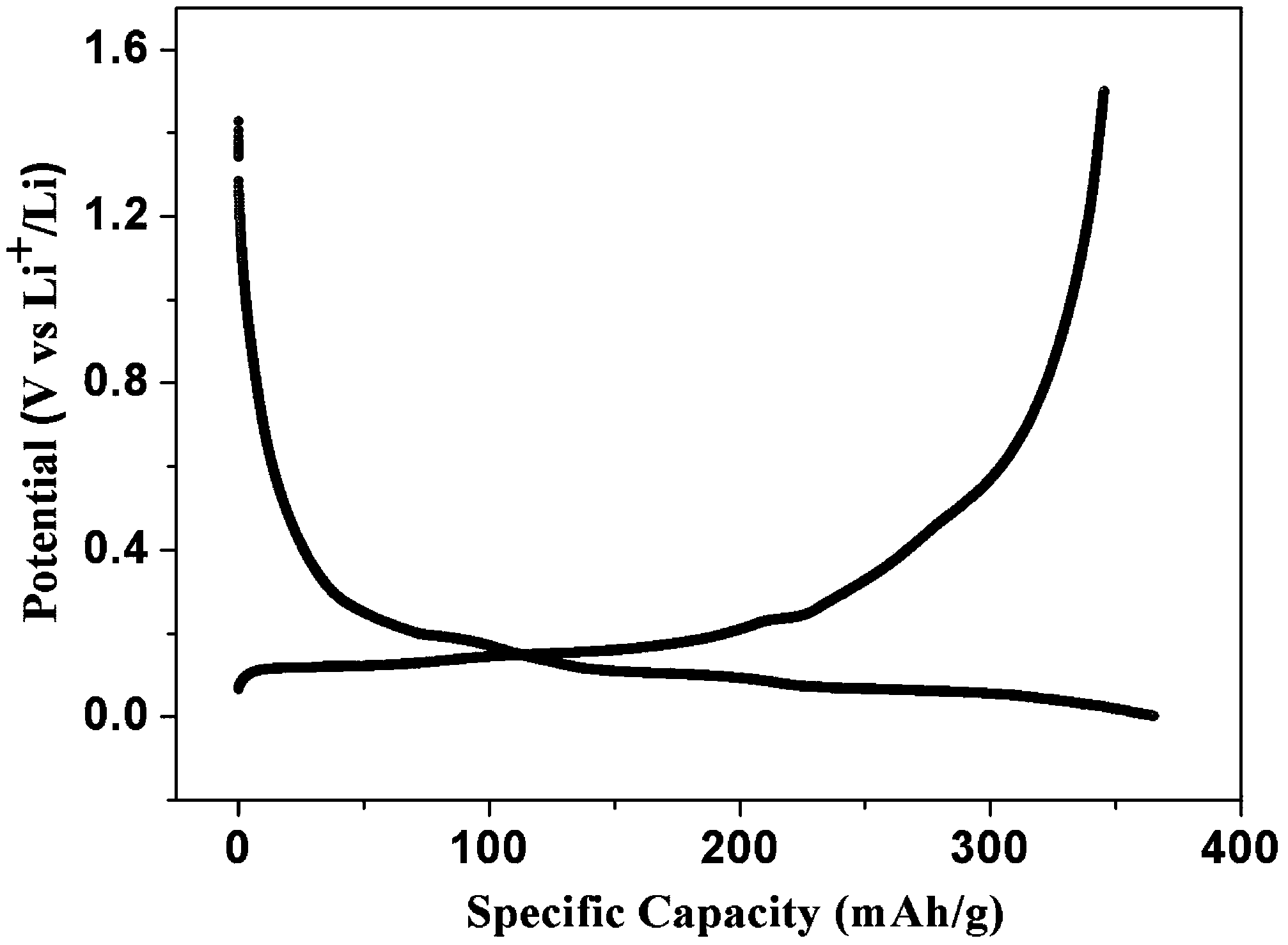

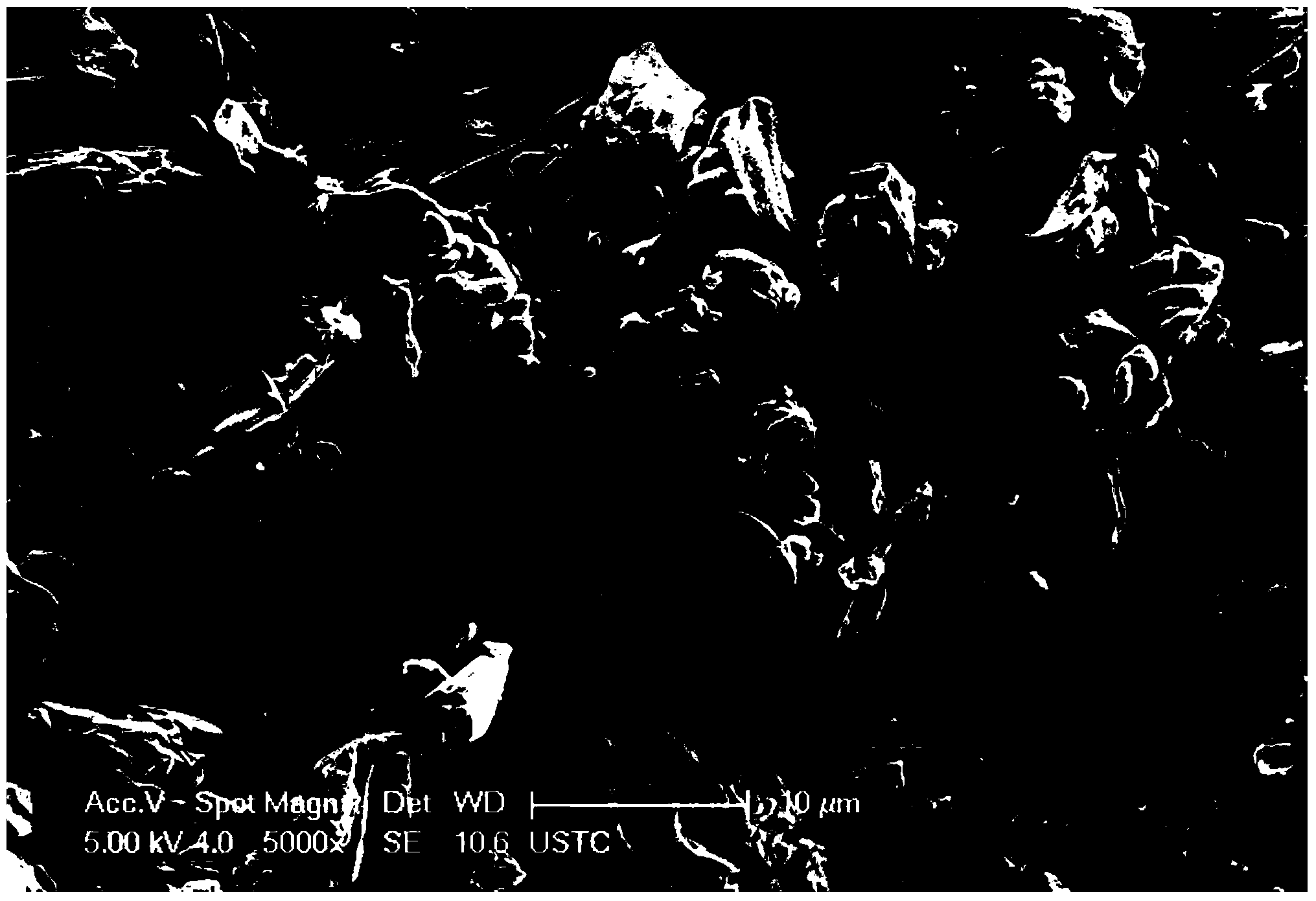

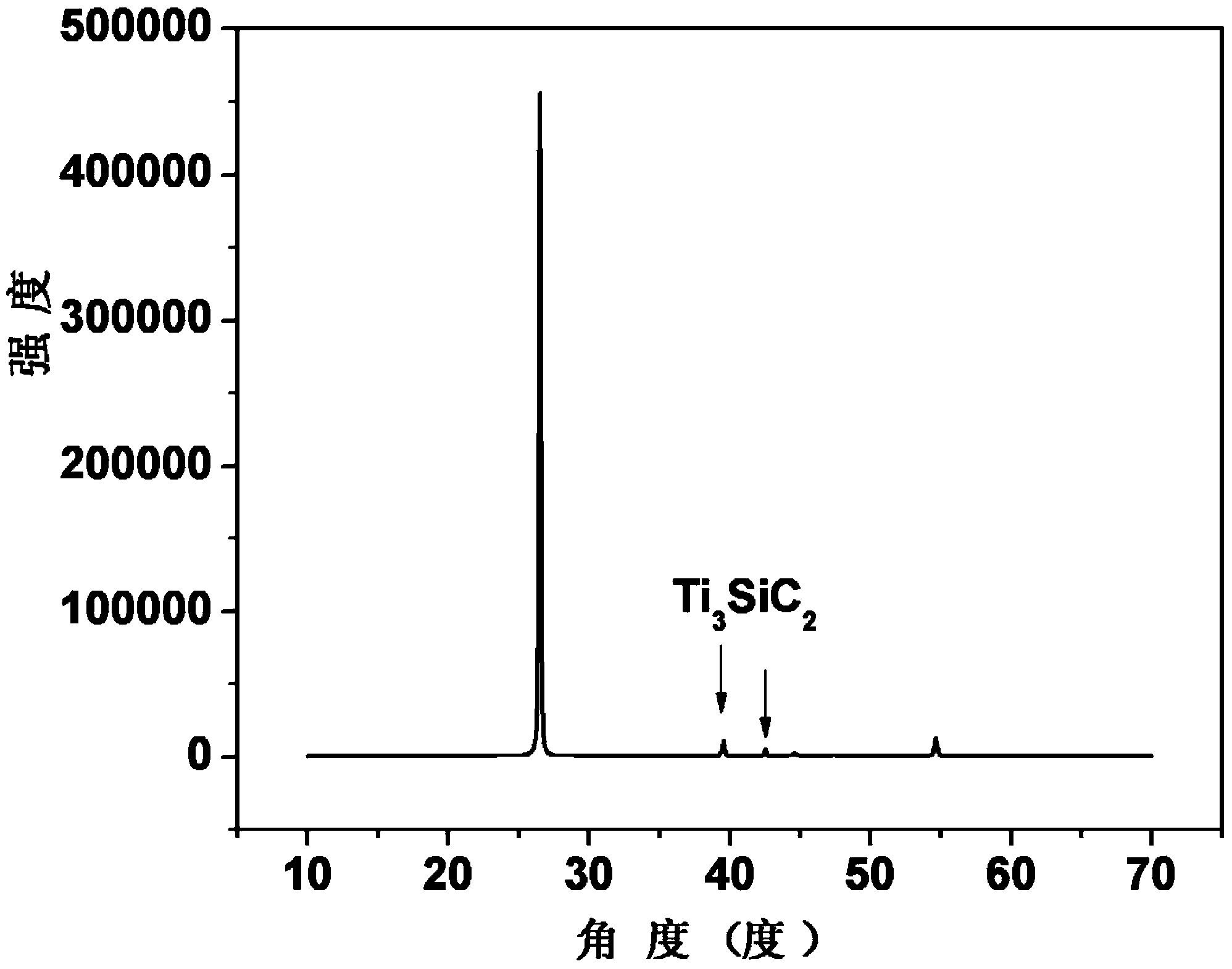

[0026] 2) Under the protection of a nitrogen-hydrogen mixed atmosphere with a hydrogen volume percentage of 1%, the obtained dry material is heated to 1550°C for 2 hours, and then cooled to 1200°C for 5 hours, the heating rate is 2°C / min, and sintered The material is naturally cooled to room temperature with the furnace, that is, a similar figure 1 curve, figure 2 with 3 The surface shown in the map has a titanium silicon carbon coated layer of graphite material.

Embodiment 2

[0028] 1) Weigh butyl titanate, silicon powder and graphite according to the molar ratio Ti:Si:C=3:1.2:800. Using 2.0% by mass of CMC in absolute ethanol as a dispersant, ultrasonic mixing was performed under the protection of argon. The obtained mixed slurry was vacuum-dried at 100° C. to obtain a dried material.

[0029] 2) The obtained dry material is heated to 1550°C for 2 hours under the protection of an argon-hydrogen mixed atmosphere with a hydrogen volume percentage of 2.5%, and then cooled to 1350°C for 5 hours at a heating rate of 5°C / min. The material is naturally cooled to room temperature with the furnace, and the following figure 1 curve, figure 2 with 3 The surface shown in the map has a titanium silicon carbon coated layer of graphite material.

Embodiment 3

[0031] 1) Weigh titanium tetrachloride, elemental silicon powder and graphite according to the molar ratio Ti:Si:C=3:1.5:2000. Ball milling and mixing treatment was carried out under the protection of argon with 2.0% PEG in absolute ethanol as the dispersant. The obtained mixed slurry was vacuum-dried at 120° C. to obtain a dried material.

[0032] 2) The obtained dried material is heated to 1550°C for 2 hours under the protection of an argon-hydrogen mixed atmosphere with a hydrogen volume percentage of 3.5%, and then cooled to 1250°C for 5 hours at a heating rate of 8°C / min, and sintered The material is naturally cooled to room temperature with the furnace, that is, a similar figure 1 curve, figure 2 with 3 The surface shown in the map has a titanium silicon carbon coated layer of graphite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com