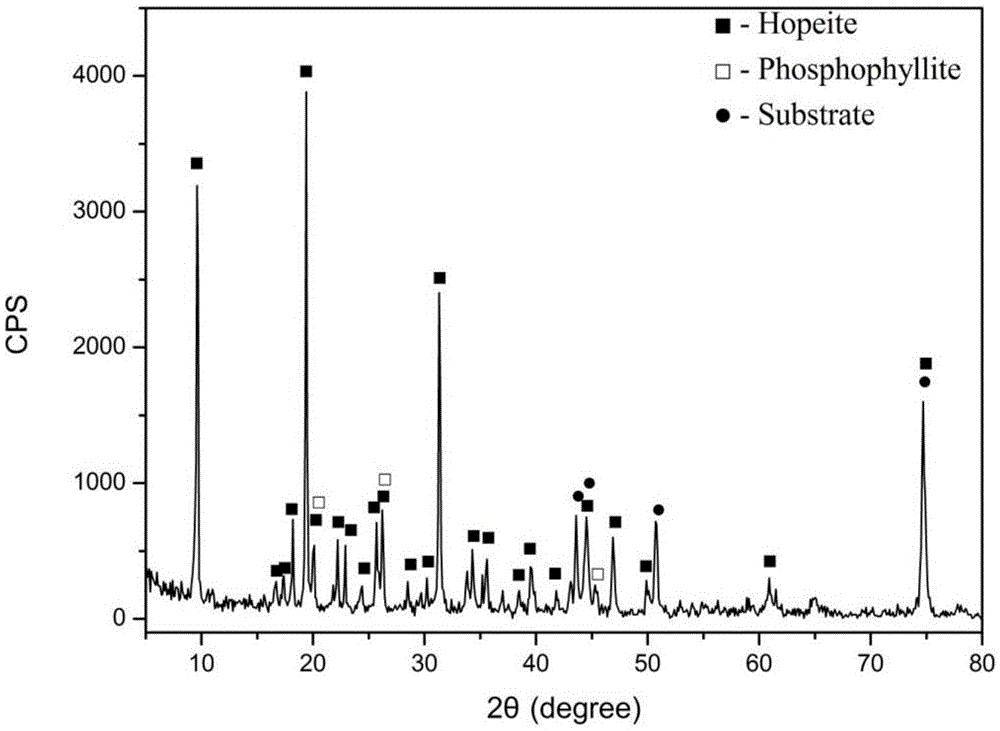

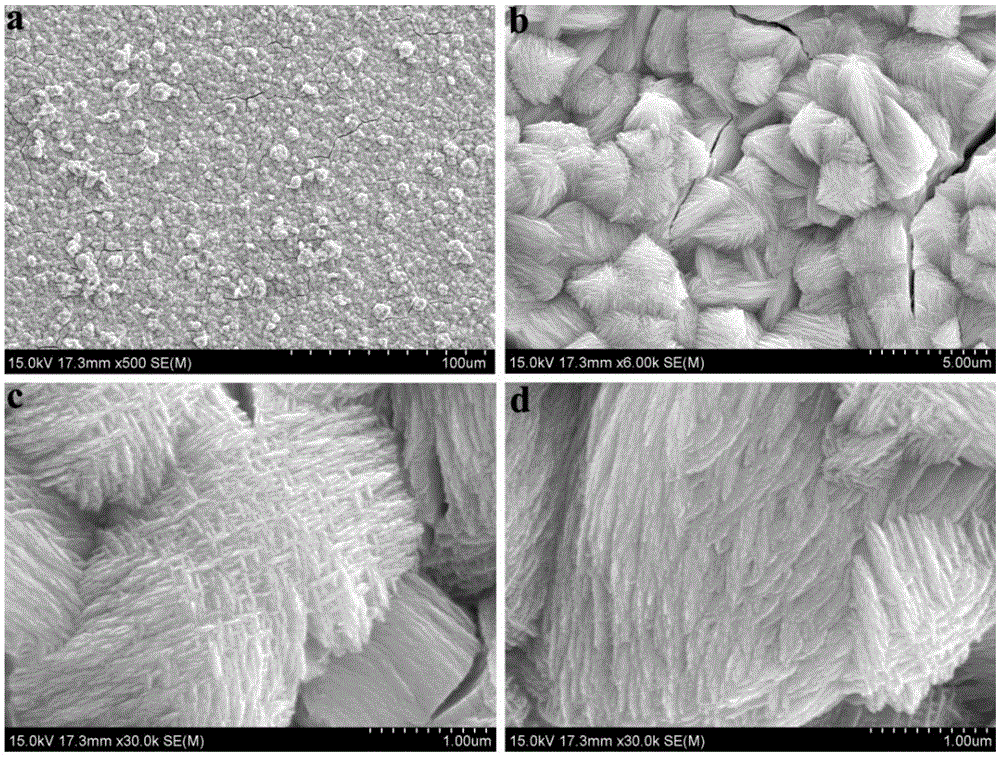

A kind of preparation method of zinc phosphate chemical conversion film with hierarchical structure

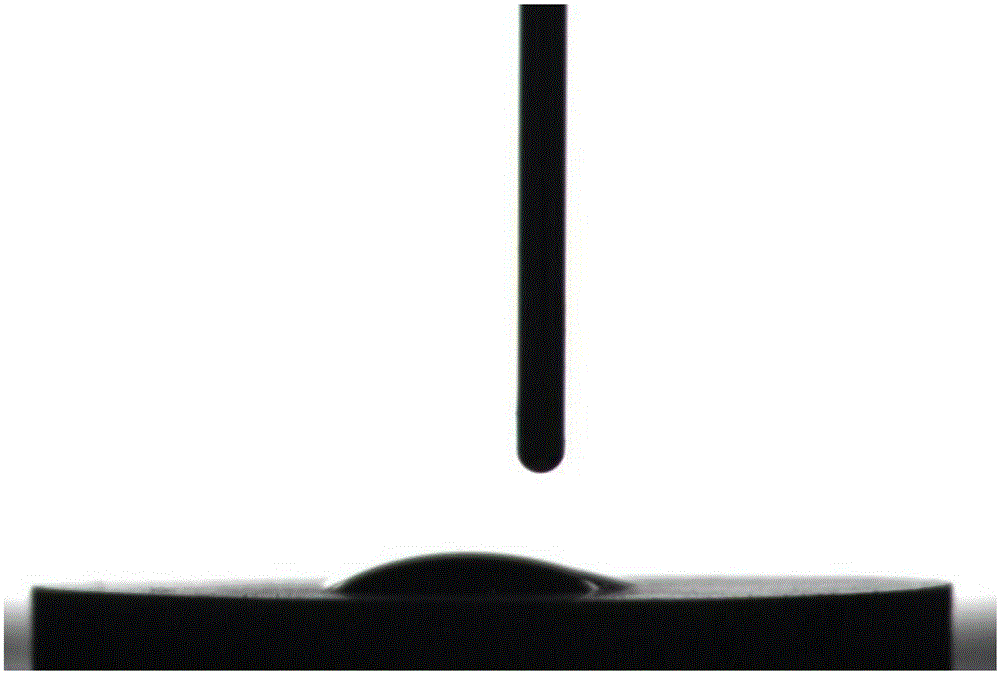

A technology of chemical conversion coating and hierarchical structure, which is applied in the field of metal surface modification, can solve the problems of inapplicable stainless steel surface modification, etc., and achieve the effects of low cost, improved corrosion resistance, and simple and easy process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of chemical conversion solution A: 25g / L zinc oxide, 30ml / L nitric acid, 15ml / L phosphoric acid, 5g / L calcium nitrate, 20g / L citric acid. Then slaking with 5g / L pure iron powder for 24h to obtain chemical conversion solution A1.

[0027] (2) Using 316 medical stainless steel as the substrate, carry out acid etching treatment with 7wt% phosphoric acid, wherein the acid etching temperature is room temperature, and the acid etching time is 10 minutes;

[0028] (3) The substrate after acid etching is subjected to surface activation treatment with colloidal titanium, the surface activation operation temperature is room temperature, and the activation time is 30s;

[0029] (4) Put the activated substrate into the solution A1, at 75° C., the pH value is 2.75, after chemical conversion for 30 minutes, rinse with water to obtain a zinc phosphate chemical conversion coating.

Embodiment 2

[0031] (1) Preparation of chemical conversion solution A: 28g / L zinc oxide, 30ml / L nitric acid, 11ml / L phosphoric acid, 10g / L calcium nitrate, 18g / L citric acid. Then slaking with 5g / L pure iron powder for 12h to obtain chemical conversion solution A1.

[0032] (2) Using 316 medical stainless steel as the substrate, carry out acid etching treatment with 7wt% phosphoric acid, wherein the acid etching temperature is room temperature, and the acid etching time is 10 minutes;

[0033] (3) The substrate after acid etching is subjected to surface activation treatment with colloidal titanium, the surface activation operation temperature is room temperature, and the activation time is 30s;

[0034] (4) Put the activated substrate into the solution A1, at 75° C., the pH value is 2.6, after chemical conversion for 30 minutes, rinse with water to obtain a zinc phosphate chemical conversion coating.

Embodiment 3

[0036] (1) Preparation of chemical conversion solution A: 22g / L zinc oxide, 28ml / L nitric acid, 15ml / L phosphoric acid, 11g / L calcium nitrate, 21g / L citric acid. Then slaking with 5g / L pure iron powder for 24h to obtain chemical conversion solution A1.

[0037] (2) Using 316 medical stainless steel as the substrate, carry out acid etching treatment with 7wt% phosphoric acid, wherein the acid etching temperature is room temperature, and the acid etching time is 10 minutes;

[0038] (3) The substrate after acid etching is subjected to surface activation treatment with colloidal titanium, the surface activation operation temperature is room temperature, and the activation time is 30s;

[0039] (4) Put the activated substrate into the solution A1, at 75° C., the pH value is 2.75, after chemical conversion for 45 minutes, rinse with water to obtain a zinc phosphate chemical conversion coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com