Combined electrolysis reactor and waste water treatment method thereof

An electrolytic reactor and reactor technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of single role of particle electrode material, low efficiency of multi-dimensional electrode treatment, and occupation of treatment equipment Large land area and other issues, to achieve the effect of compact structure, small footprint, and enhanced efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

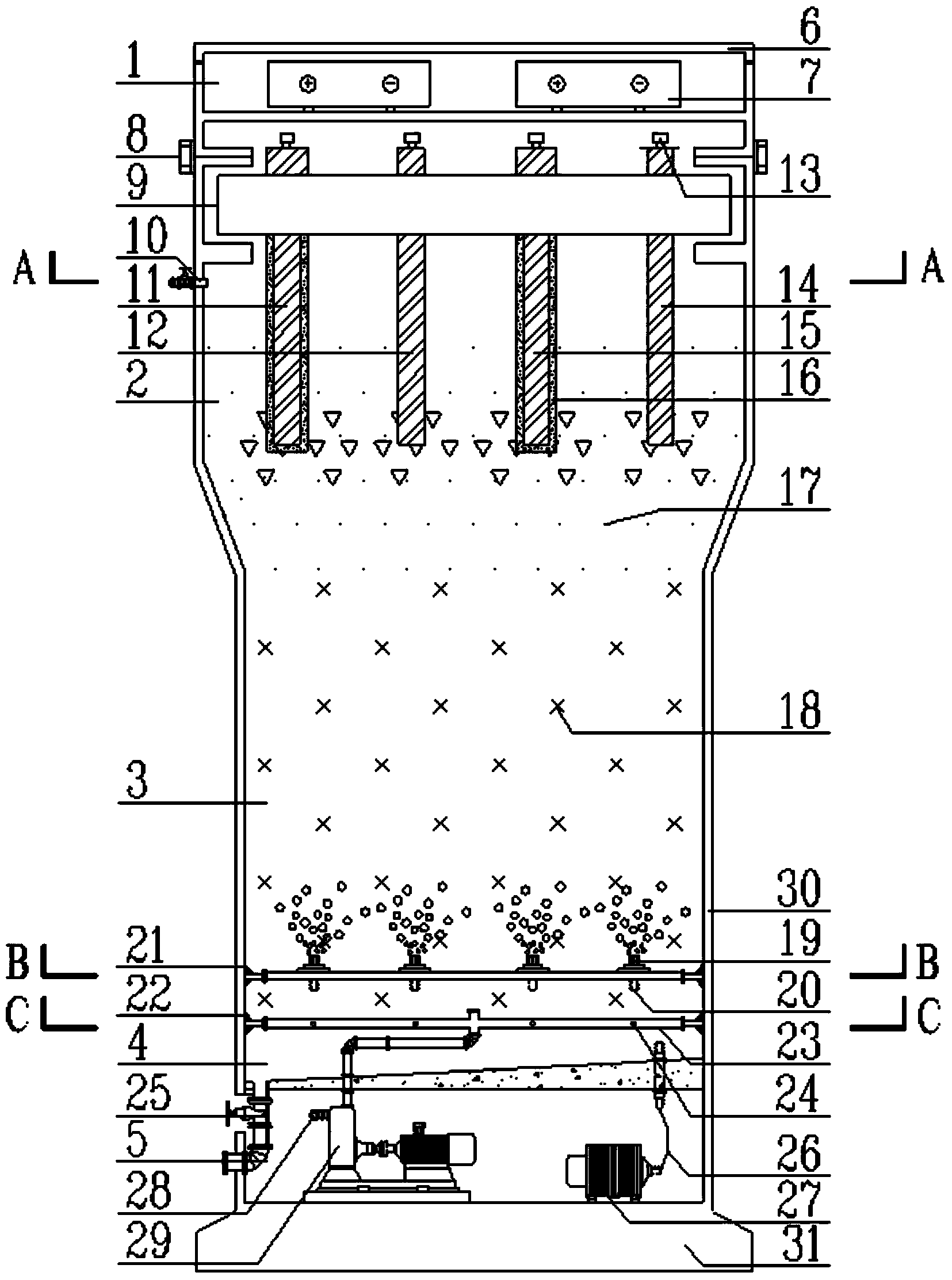

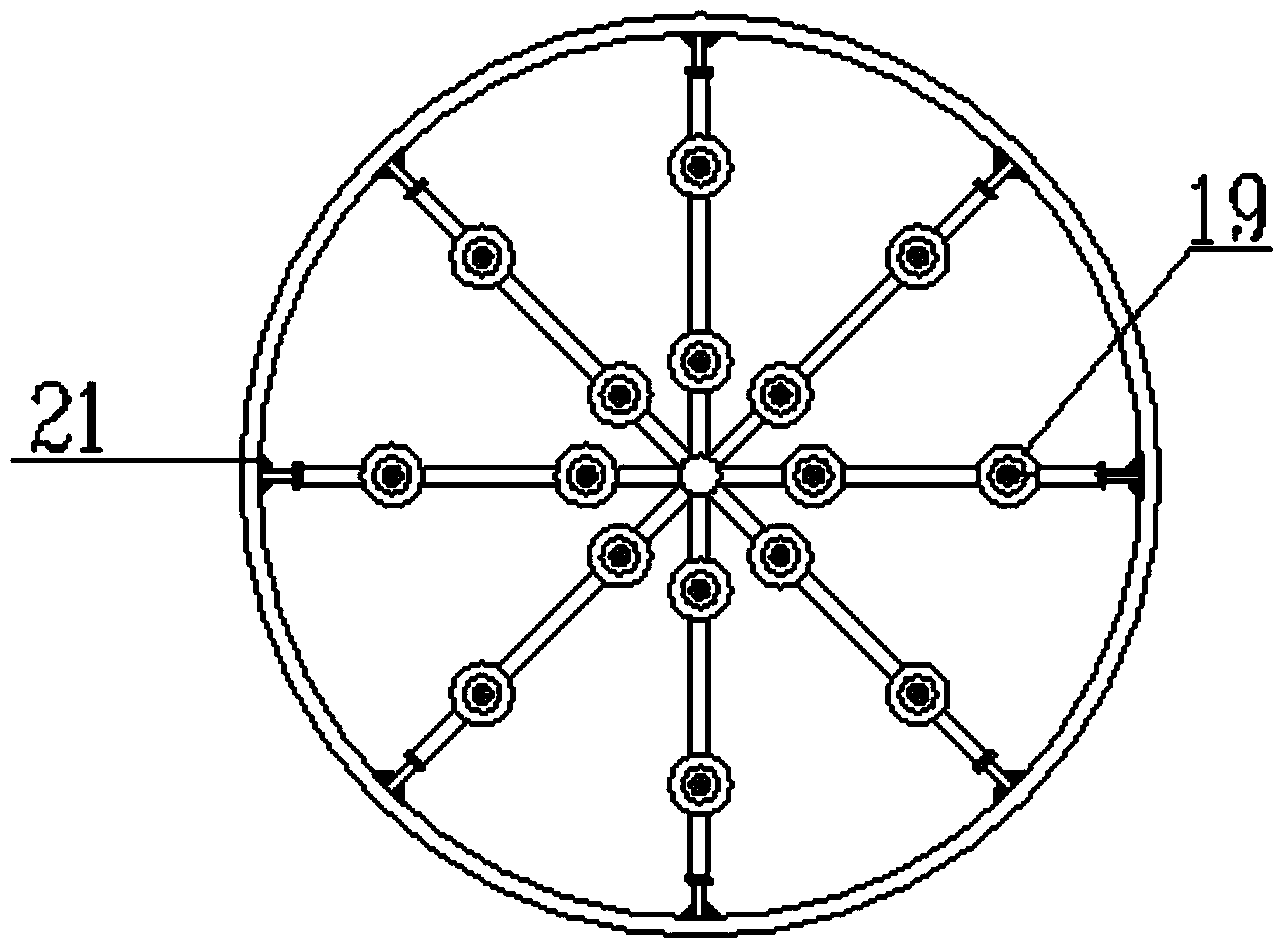

[0043] Such as figure 1 , the combined electrolytic reactor of the present embodiment is a cylindrical structure, and the reactor 30 is fixed on the reactor base 31, and the overall height of the reactor 30 is 5.1m, and it includes a power supply chamber 1, a multidimensional electrode chamber 2, an iron-carbon micro-electrolysis chamber 3, Water distribution aeration room 4, equipment room 5.

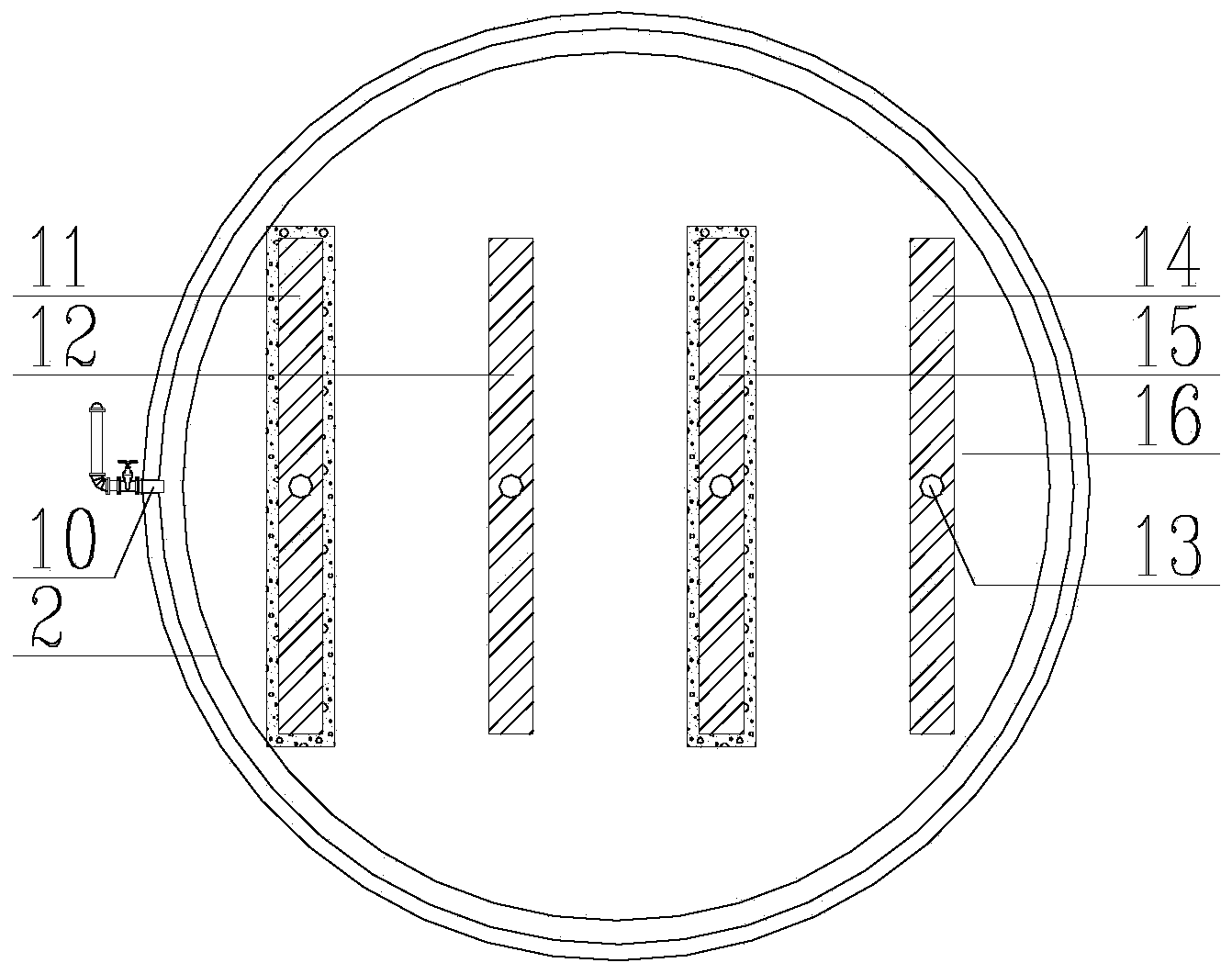

[0044] The power supply room 1 is located in the top cover 6 of the reactor, equipped with two power supply controllers 7; the top cover 6 of the reactor is 0.4m high, and the applied voltage is 220V. The multi-dimensional electrode chamber 2 is located at the lower part of the top cover 6 of the reactor, with a diameter of 0.4 m and a height of 2.0 m, including four electrode plates, electrode plate a11, electrode plate b12, electrode plate d15 and electrode plate c14 ( The top of each electrode plate is provided with terminal 13, the surface of the electrode plate is 60 * 60cm, and ...

Embodiment 2

[0059] This embodiment is based on a kind of combined electrolytic reactor of above-mentioned embodiment 1 as an example to carry out wastewater treatment, certain dye wastewater, active green KE-4BD wastewater initial concentration is 360-400mg / L, CODc r : 275-308mg / L, pH: 4.5-5.0, chromaticity: 1200-1500 times.

[0060] The main anode of the reactor is based on iron plate, which is treated with metal coating, the metal coating is ruthenium iridium, the main cathode is based on stainless steel plate; the material of carbon filler is activated carbon.

[0061] Wastewater treatment process, the steps are as follows:

[0062] (1) In the water inlet stage, the reactor inlet water flow rate is 35m 3 / h, the water intake time is 0.2h;

[0063] (2) In the reaction stage, the working voltage of the multi-dimensional electrode is 220V, and the current density is 30mA / cm 3 , the opening time is 0.8h, the working time of the aeration pump 27 is 2.0h, the aeration volume in the first ...

Embodiment 3

[0068] This embodiment is based on a combined electrolytic reactor in the above-mentioned embodiment 1 as an example for wastewater treatment. A certain printing and dyeing wastewater has a water quality of CODc r : 520-580mg / L, pH: 10.5-11.0, chroma: 400-500 times.

[0069] The main anode of the reactor is based on iron plate, which is treated with metal coating, the metal coating is iron ruthenium tin, the main cathode is based on stainless steel plate; the material of carbon filler is anthracite.

[0070] Wastewater treatment process, the steps are as follows:

[0071] (1) In the water inlet stage, the reactor inlet water flow rate is 30m 3 / h, the water intake time is 0.25h;

[0072] (2) In the reaction stage, the working voltage of the multi-dimensional electrode is 220V, and the current density is 40mA / cm 3 , the opening time is 1.0h, the working time of the aeration pump 27 is 2.0h, the aeration volume for the first 1.0h is 40L / min, and the aeration volume for the ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com