Engineering bacteria based on beta-glucosidase and implementation method thereof

A technology of glucosidase and engineering bacteria, which is applied to engineering bacteria based on β-glucosidase and its realization field, and can solve problems such as insufficient development and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Cultivation of Streptomyces griseorubens JSD‐1

[0033] Streptomyces griseorubens was isolated from the rotting soil of Pujiang Town, Shanghai, and the preservation number is CGMCC No.5706; the strain was preserved in the Chinese Academy of Microbiology Research Center of General Microbiology, Chinese Academy of Sciences on January 9, 2012 Office (Address: No. 3, No. 1 Yard, Beichen West Road, Chaoyang District, Beijing 100101)

[0034] The bacteria were inoculated in LB liquid medium, cultured at 32°C for 60 hours, the bacteria were collected by centrifugation and the genomic DNA of the bacteria was extracted.

[0035] The components of the LB liquid medium are: 10 g of peptone, 5 g of yeast extract, 5 g of NaCl, 1 L of deionized water, and pH 6.8-7.2.

Embodiment 2

[0037] Cloning of the β-glucosidase (Sg-Gcd) Gene of Streptomyces grisea

[0038] Through the analysis of the β-glucosidase gene sequence of Streptomyces grisea, the primers containing NdeI and EcoRI restriction sites were designed as follows:

[0039] Forward primer Gcd-NdeI-F, as shown in SEQ ID No.3:

[0040] 5'-GGAATTCCATATGATCCGGGCCATGGCGACGACGAACCC-3'

[0041] Reverse primer Gcd-EcoRI-R, as shown in SEQ ID No.4:

[0042] 5'-GGAATTCTCAGTCCCGCTGCTCCCGCAGCAGCGCGCGGT-3'

[0043] Genomic DNA of Streptomyces grisea JSD-1 was used as a template, and PrimeSTAR GXL high-fidelity enzyme (TaKaRa) was used for amplification. The PCR amplification conditions were: pre-denaturation at 98°C for 3 min; deformation at 98°C for 10 s, extension at 68°C for 1 min; and final extension at 68°C for 3 min after 30 cycles.

Embodiment 3

[0045] Construction of cloning vector containing β-glucosidase (Sg-Gcd) gene

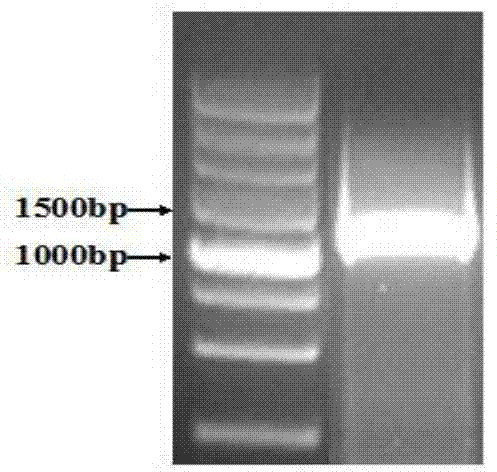

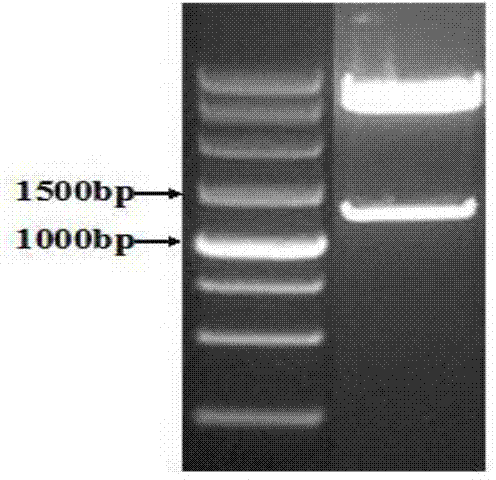

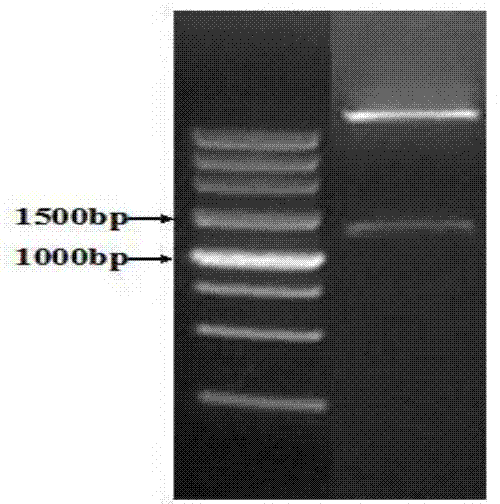

[0046] The PCR amplification product is carried out electrophoresis detection, and the result shows that the obtained fragment is about 1.3Kb (see figure 1 ); then the PCR product was gel-cut and recovered and connected to pEASY-Blunt Simple Cloning Vector (Beijing Quanshijin), and then introduced into DH5α Escherichia coli competent cells.

[0047] Pick clones with corresponding resistance and identify them by colony PCR until positive clones are obtained; pick positive clones, shake the bacteria to extract their plasmids, and send them to Shanghai Sonny Biological Co., Ltd. for sequencing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com