Fermentation tea juice and preparation method thereof

A technology of fermented tea juice, which is applied in the field of fermented tea juice and its preparation, can solve problems such as being easily affected by light and heat, low bioavailability, and affecting taste, and achieves low ash content, rich functional substances, and The effect of taste improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

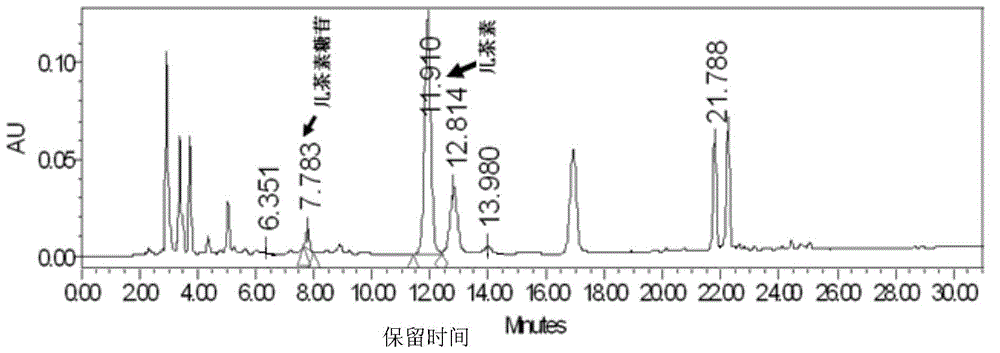

Image

Examples

Embodiment 1

[0045] (1) Take 3kg of fresh green tea, crush it to a 10-mesh sieve, then add water (the weight ratio of tea to water is 1:17) and compound enzyme (the compound enzyme is composed of cellulase, pectinase and protease, wherein each enzyme is mixed with The mass fraction in the liquid is 0.35%) continuous countercurrent leaching, the leaching temperature is 50° C., the time is 40 min, and the leaching is performed twice to obtain the leaching solution.

[0046] (2) 0.6 U / mL of β-glucosidase was added to the extract, and the enzymatic hydrolysis temperature was 45° C. for 300 minutes.

[0047] (3) The enzymatic solution is passed through a 100-mesh vibrating sieve, the filtrate is cooled to room temperature through a heat exchanger, and then centrifuged in a disc centrifuge with a rotating speed of 7500 rpm and a slag discharge cycle of 300 seconds to obtain tea juice. The tea juice is concentrated through the reverse osmosis membrane, so that the concentration of tea polyphenols...

Embodiment 2

[0075] Green tea was used as raw material without β-glucosidase enzymatic hydrolysis, and other steps were the same as in Example 1 to prepare fermented tea juice.

[0076] The physicochemical components in the fermentation broth were analyzed, and the analysis method was referred to Example 1.

[0077] The results are: solid content 3850mg / 100mL, ash content 287mg / 100mL, total catechin 1871mg / 100mL, catechin glycoside 918mg / 100mL, theanine 169mg / 100mL, total amino acid 587mg / 100mL, oligopeptide 397mg / 100mL 100mL, total acid (calculated as lactic acid) is 482mg / 100mL, reducing sugar is 694mg / 100mL, and the conversion rate of catechin is 24.3%. It can be seen that the solid content of the tea juice fermented beverage prepared by this process is 3850mg / 100mL, and the total amount of catechins, catechin glycosides, theanine, total amino acids, oligopeptides, and total High acid and reducing sugar content, rich functional substances, low ash content, good product quality, but rel...

Embodiment 3

[0080] (1) Take 5kg of fresh black tea, crush it to a 10-mesh sieve, then add water (the weight ratio of tea to water is 1:24) and compound enzyme (the compound enzyme is composed of cellulase, pectinase and protease, wherein each enzyme is mixed with The mass fraction in the liquid is 0.25%) continuous countercurrent leaching, the leaching temperature is 50° C., the time is 70 min, and the leaching is done twice to obtain the leaching solution.

[0081] (2) Add β-glucosidase 1.0 U / mL to the extract solution, the enzymolysis temperature is 55° C., and the time is 180 min.

[0082] (3) The enzymolyzed solution is passed through an 80-mesh vibrating sieve, the filtrate is cooled to room temperature through a heat exchanger, and then centrifuged in a disc centrifuge with a rotating speed of 7000 rpm and a slag discharge period of 200 seconds to obtain tea juice. The tea juice is concentrated through the reverse osmosis membrane, so that the concentration of tea polyphenols in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com