Preparation and application of catalyst for advanced treatment of printing and dyeing waste water by Fenton-like process

A printing and dyeing wastewater and advanced treatment technology, applied in the field of water treatment technology and functional materials, can solve the problem of high cost, achieve the effect of low production cost, mild reaction conditions, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

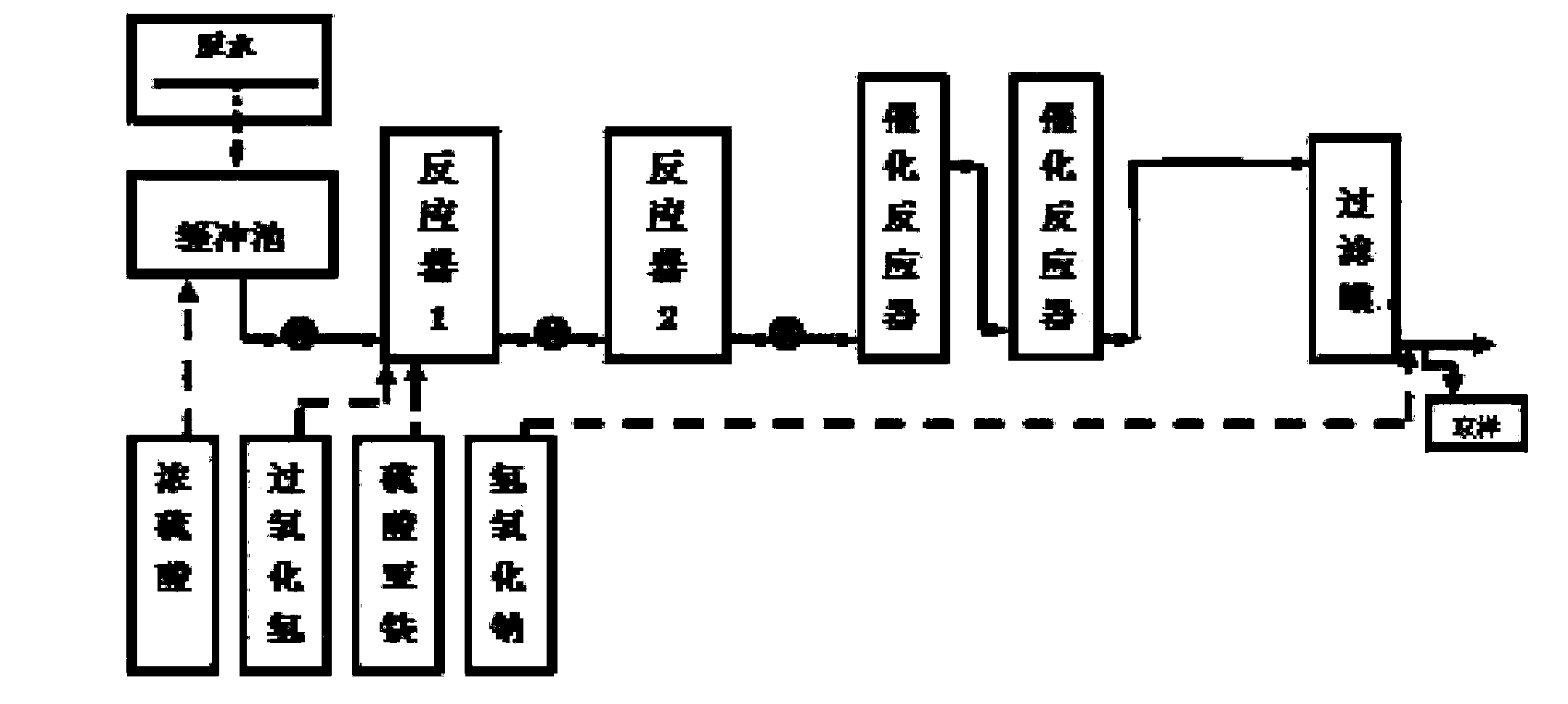

Method used

Image

Examples

Embodiment 1

[0028] ① Dissolve 0.2mol of zirconium oxychloride and 0.8mol of aluminum nitrate in 2.5L of ultrapure water, add 5ml of nitric acid and 100ml of hydrogen peroxide, and stir vigorously for 20 minutes to prepare a zirconium-aluminum composite salt solution.

[0029] ②The zirconium-aluminum compound salt solution was added dropwise to 1L of 12.5% ammonia water at a rate of 15ml / min to form a white jelly.

[0030] ③ The colloid was aged at room temperature for 12 hours, vacuum filtered and washed, and the obtained filter cake was fully kneaded and extruded.

[0031] ④ After the extrudate is dried at room temperature, it is dried at 120°C for 2 hours, and then calcined in one or two steps at 500-800°C for 2-8 hours. The carrier number is zirconium-aluminum composite oxide carrier-1.

Embodiment 2

[0033] ① Dissolve 0.2mol of zirconium oxychloride and 0.8mol of aluminum nitrate in 2.5L of ultrapure water, add 5ml of nitric acid, and stir vigorously for 20 minutes to prepare a zirconium-aluminum composite salt solution.

[0034] ②The zirconium-aluminum compound salt solution was added dropwise to 1L of 12.5% ammonia water at a rate of 15ml / min to form a white jelly.

[0035]③ The colloid was aged at room temperature for 12 hours, vacuum filtered and washed, and the obtained filter cake was fully kneaded and extruded.

[0036] ④ After the extrudate is dried at room temperature, it is dried at 120°C for 2 hours, and then calcined in one or two steps at 500-800°C for 2-8 hours. The carrier number is zirconium aluminum composite oxide carrier-2.

Embodiment 3

[0038] ① Prepare different concentrations of copper nitrate, nickel nitrate, and ferric nitrate solutions.

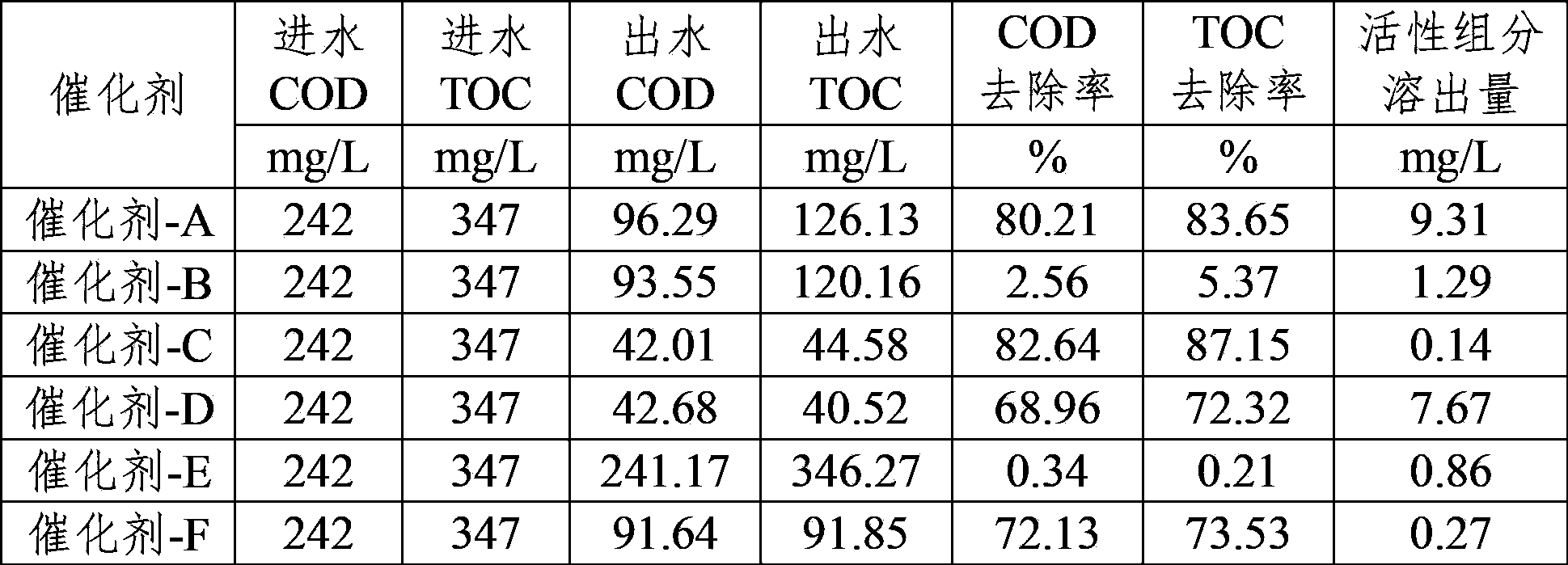

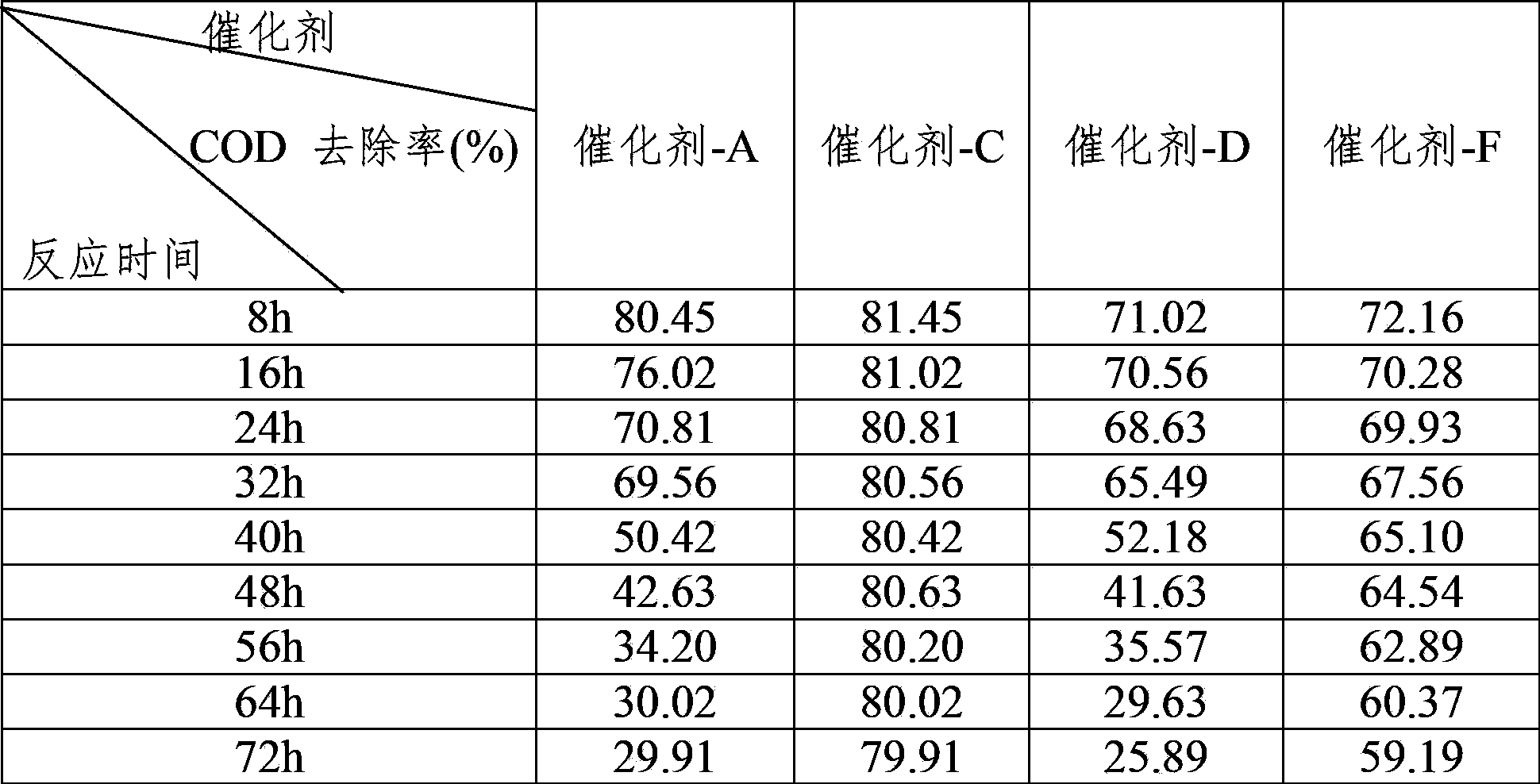

[0039] ②Impregnate zirconium-aluminum composite oxide carrier-1 in acid copper, nickel nitrate, and ferric nitrate solution respectively, impregnate overnight at room temperature, dry at 110°C for 3h, and then calcinate at 400°C for 3h to obtain active components (based on metal elements) with a loading of 2% catalyst. They are numbered Catalyst-A, B, and C respectively.

[0040] ③Impregnate zirconium-aluminum composite oxide carrier-2 in acid copper, nickel nitrate, and ferric nitrate solutions, impregnate overnight at room temperature, dry at 110°C for 3h, and then calcinate at 400°C for 3h to obtain active components (based on metal elements) with a loading of 2% catalyst. They are numbered Catalyst-D, E, F respectively.

[0041] The catalyst is used to treat the refractory printing and dyeing wastewater passing through the biochemical pool, the initial reaction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com