Method for preparing chemical conversion film on aluminum alloy surface on basis of molybdate

A chemical conversion coating, aluminum alloy surface technology, applied in the field of aluminum alloy surface treatment, can solve the problem of solution stability, application limitation, colorless film and other problems, achieve low cost, low component content, neutral salt resistance good fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

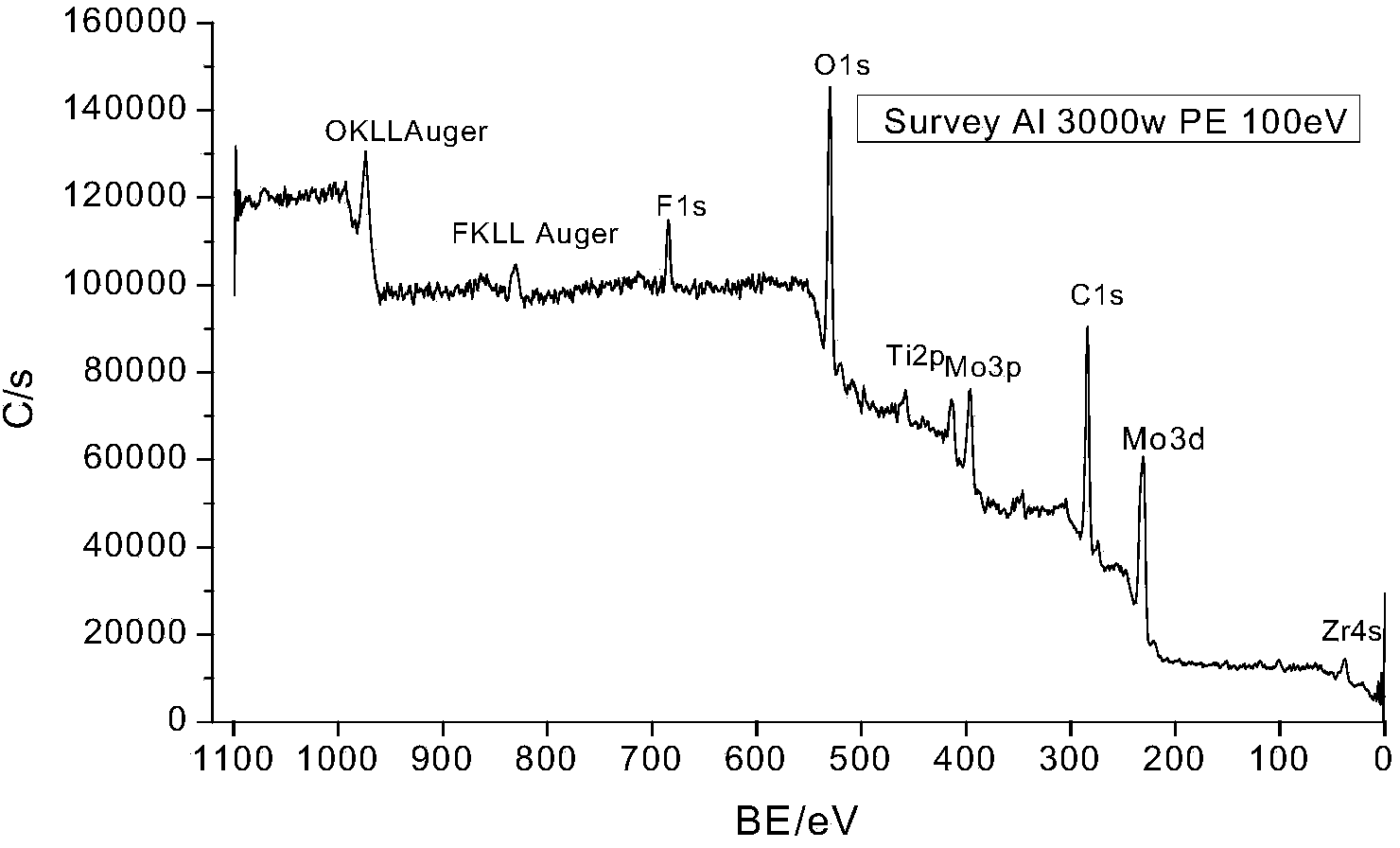

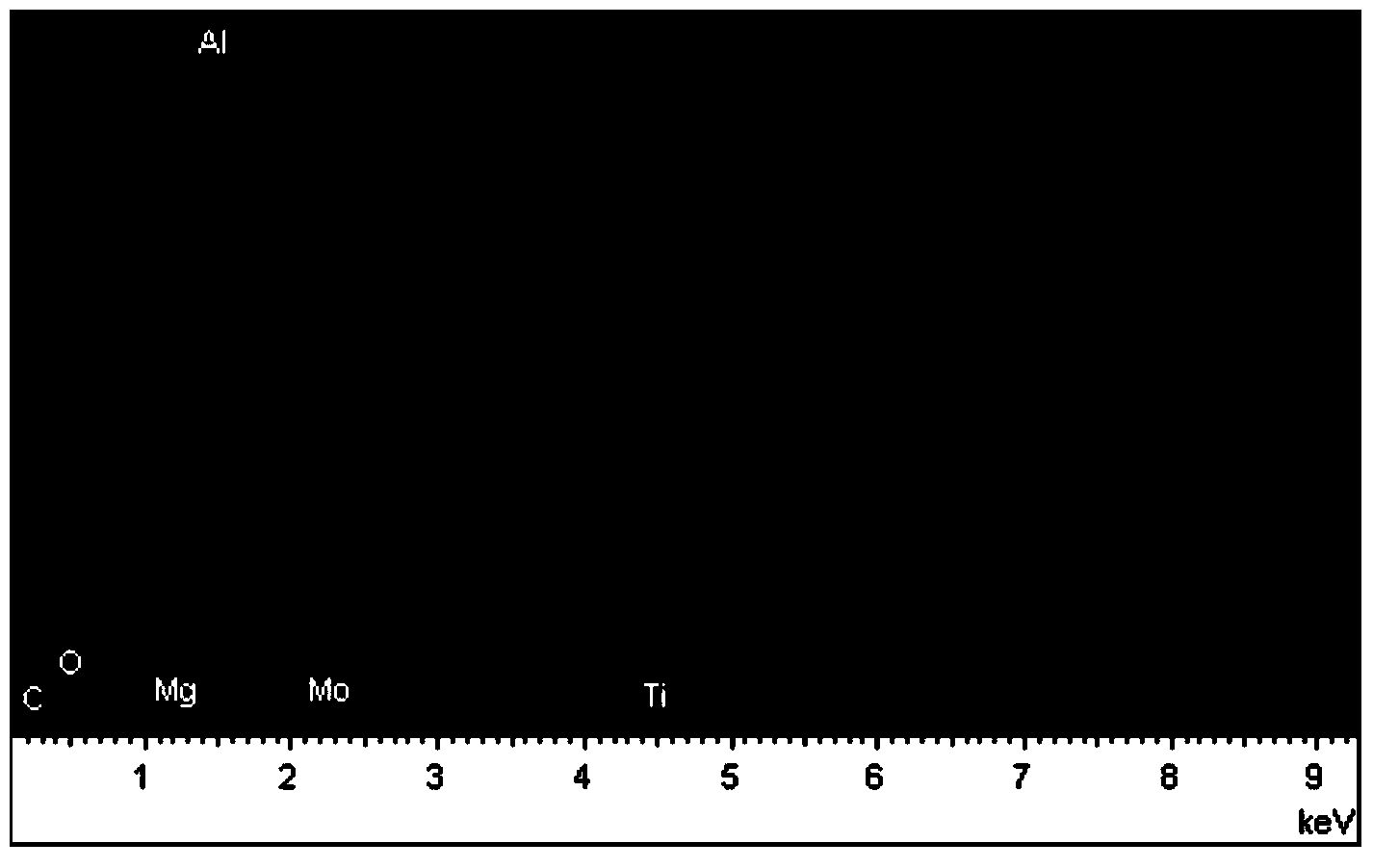

Image

Examples

Embodiment 1

[0030] Proceed as follows:

[0031] (1) Configuration of the treatment solution: 0.5g / L sodium molybdate, 2g / L potassium fluotitanate, 0.8g / L potassium fluozirconate, 0.8g / L tricitric acid in distilled water in sequence Sodium treatment solution 500ml, adjust the pH value of the solution in the range of 3.0-3.4 with dilute nitric acid for later use.

[0032] (2) Aluminum alloy pretreatment: Soak 6036 aluminum alloy in commercially available acid degreasing solution for 5min-10min, then rinse with tap water for 1min-2min, then rinse with distilled water until the oil is removed, and finally dry it for later use.

[0033] (3) Chemical conversion of aluminum alloy: the aluminum alloy cleaned in step (2) is placed in the above treatment solution for chemical conversion, the temperature is controlled at 25°C-30°C, and the treatment time is 5 minutes.

[0034] (4) Wash and dry the aluminum alloy transformed in step (3), and it can be seen that there is a golden yellow conversion fi...

Embodiment 2

[0037] Proceed as follows:

[0038] (1) Configuration of treatment liquid: 0.3g / L sodium molybdate, 2g / L potassium fluotitanate, 0.8g / L potassium fluozirconate, 0.8g / L tricitric acid were prepared in distilled water in sequence Sodium treatment solution 500ml, adjust the pH value of the solution in the range of 3.0-3.4 with dilute nitric acid for later use.

[0039] (2) Aluminum alloy pretreatment: Soak 6036 aluminum alloy in acid degreasing solution for 5min-10min, then rinse with tap water for 1min-2min, then rinse with distilled water until the oil is removed, and finally dry it for later use.

[0040] (3) Chemical transformation of aluminum alloy: the aluminum alloy cleaned in step (2) is placed in the above treatment solution for chemical transformation, the temperature is controlled at 30°C-31°C, and the treatment time is 5 minutes.

[0041] (4) Wash and dry the aluminum alloy transformed in step (3), and it can be seen that there is a golden yellow conversion film on t...

Embodiment 3

[0044] Proceed as follows:

[0045] (1) Configuration of the treatment solution: 0.6g / L sodium molybdate, 2g / L potassium fluotitanate, 0.8g / L potassium fluozirconate, 0.4g / L tricitric acid in distilled water in sequence Sodium treatment solution 500ml, adjust the pH value of the solution in the range of 3.0-3.4 with dilute nitric acid for later use.

[0046] (2) Aluminum alloy pretreatment: Soak 6036 aluminum alloy in acid degreasing solution for 5min-10min, then rinse with tap water for 1min-2min, then rinse with distilled water until the oil is removed, and finally dry it for later use.

[0047] (3) Chemical transformation of aluminum alloy: the aluminum alloy cleaned in step (2) is placed in the above treatment solution for chemical transformation, the temperature is controlled at 30°C-31°C, and the treatment time is 5 minutes.

[0048] (4) Wash and dry the aluminum alloy transformed in step (3), and it can be seen that there is a golden yellow conversion film on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com