Drawing die for tinned copper wire wrapped with diamond metal sintered body and preparation method thereof

A technology of metal sintering and tinned copper wire, applied in the direction of drawing dies, etc., can solve the problems of large deviation in service life, large brittleness, easy cracking, etc., and achieve the effect of increasing the number of repairs, ensuring strength, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

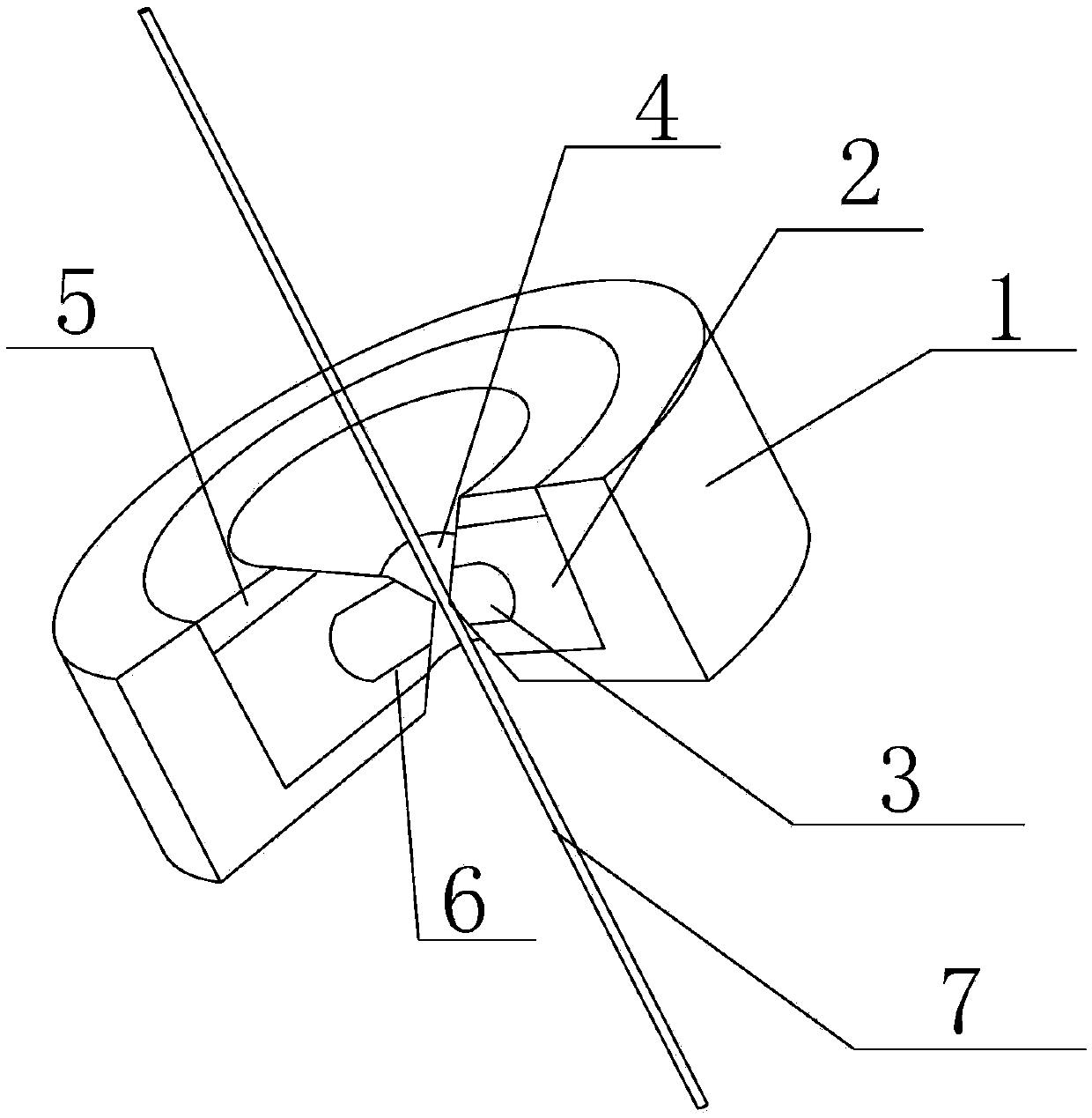

[0021] The preparation method of the drawing die of the present embodiment comprises the following steps:

[0022] (1) Put part of the mixed metal powder into the mold shell 1, cover the gland 5, compact it at room temperature on the sintering press, and take out the gland 5;

[0023] (2) Put a diamond particle 3 into the center of the metal powder compacted in step (1); the diamond particle 3 is 0.02 carats to 0.03 carats, and the diameter of the effective overlapping area is 0.6 mm;

[0024] (3) Put the remaining mixed metal powder into the mold shell 1 again, cover the gland 5, put it into a sintering press for high-temperature sintering and compaction; heat the mold shell 1 added with the mixed metal powder, and heat it while heating Apply pressure, heat to 900-1100°C and keep the temperature constant, heat to the set temperature and pressurize to 4.5MPa and then keep the pressure constant, the heating and pressing time is 3-5 minutes in total;

[0025] (4) Hole the cente...

Embodiment 2

[0030] The mixed metal powder of this embodiment includes Al60, Ni30%, Ti8%, Fe1%, Cl%. Other implementations are the same as in Example 1.

Embodiment 3

[0032] The mixed metal powder of this embodiment includes Al55%, Ni35%, Ti5%, Fe4%, Cl%. Other implementations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com