Method for manufacturing motorcycle cooling pump gear

A manufacturing method and cooling pump technology, which are applied in the direction of manufacturing tools, material forming presses, presses, etc., can solve the problem that the cooling pump gear does not meet the basic requirements for use, the milling end face keyway and the shaving tooth production efficiency is low, energy, energy, The waste of human resources and other problems can ensure the stability of product quality, minimal machining allowance, and save steel raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

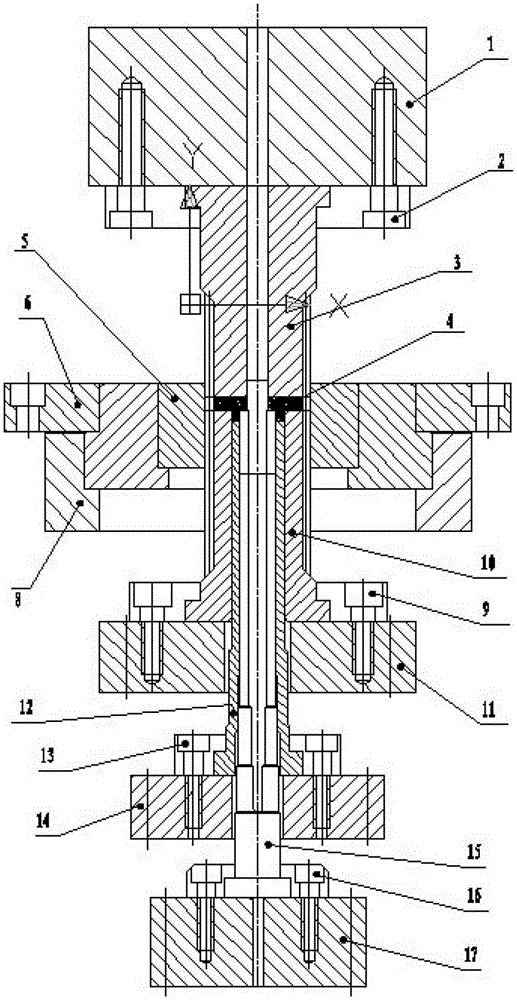

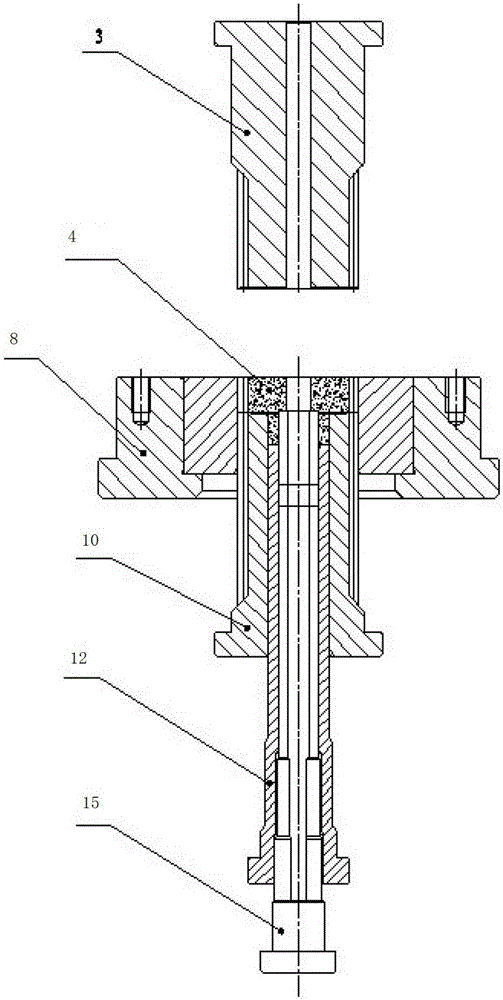

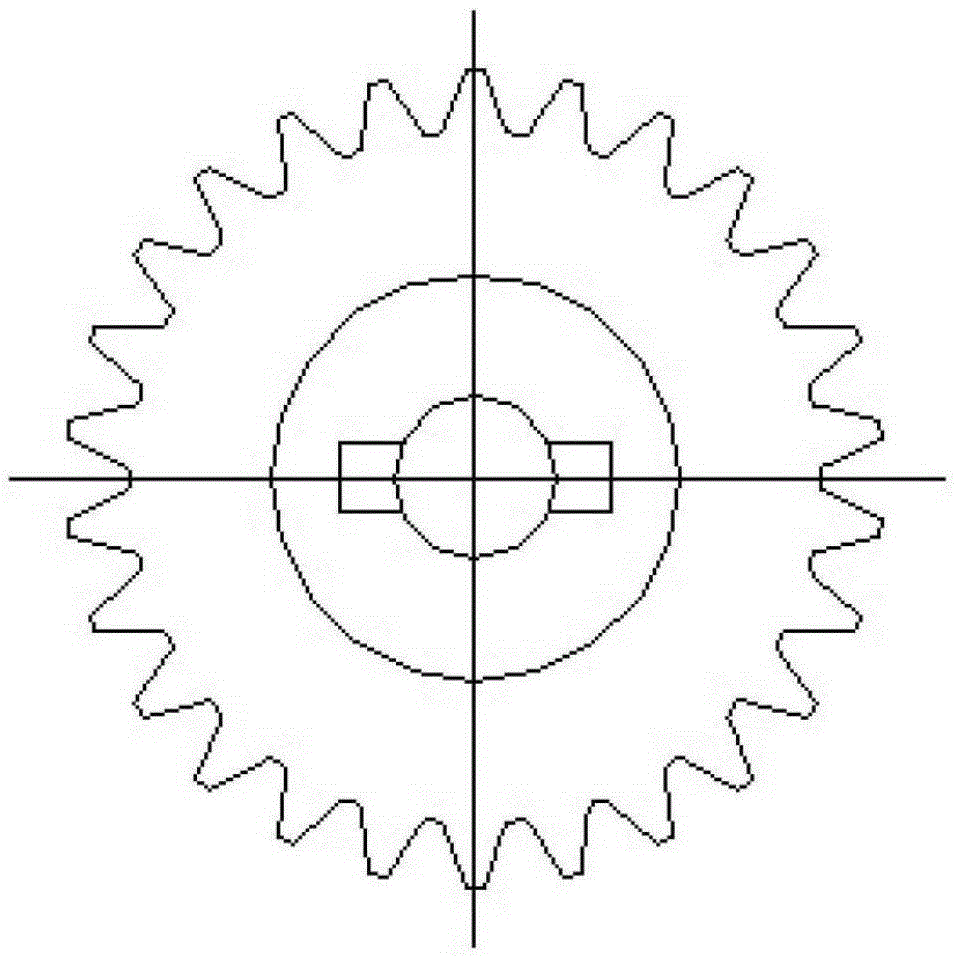

[0029] Example 1, see figure 1 , 3 , 4: A mold for manufacturing motorcycle cooling pump gears, including a cylindrical die 5 with a boss on the outer surface, an upper punch 3, a next punch 10 and a second punch 12, the next punch 10 Penetrate into the gear cavity of the female mold 5, the lower second punch 12 penetrates into the next punch 10, the female mold 5 is provided with a gear cavity through the axis, the lower second punch 12 The lower three punches 15 with bosses are sleeved inside. The upper part of the bosses of the lower three punches 15 is a cylinder, and the lower part is a cylinder with symmetrical protrusions. The cylinder is connected with a In the upper punch 3 of the central through hole, by pressing the gear cavity wall of the female mold 5, the underside of the upper punch 3, the upper end faces of the next punch 10 and the lower second punch 12, and the bosses of the lower third punch 15 1. Metal powder in the cavity formed by the outer surface of t...

Embodiment 2

[0033] Embodiment 2, a kind of manufacturing method of motorcycle cooling pump gear, is raw material with metal powder, and metal powder is selected two or more in iron powder, copper powder, nickel powder and molybdenum powder, adds graphite powder, described Graphite powder is graphite powder for powder metallurgy, mixed with a lubricant, filled into a mold, pressed and sintered.

[0034] Before pressing and forming, the metal powder, graphite powder and lubricant are mixed in a mixing equipment. The mixing equipment is a conical mixer, a V-shaped mixer or a three-dimensional mixer, and the mixing time is 50 minutes.

[0035] Pressing adopts hydraulic press or mechanical press, and the process conditions are pressing pressure: 100 tons; pressing product density: 7.0g / cm 3 .

[0036] The sintering adopts a mesh belt furnace or a boat pusher furnace, the sintering atmosphere is nitrogen-hydrogen mixed gas, and the process conditions are sintering temperature: 1150°C; sinterin...

Embodiment 3

[0037] Embodiment 3, a kind of manufacturing method of motorcycle cooling pump gear, referring to embodiment 1, differs from embodiment 1 in that the mixing time is 30 minutes; the pressing process condition is a pressing pressure of 90 tons; the pressing product density is 6.8g / cm 3 .

[0038] The sintering process conditions are as follows: the sintering temperature is 1000° C.; the sintering time is 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com