Modified lignin intumescent flame retardant TPO composite material as well as preparation method and application of composite material

A composite material and intumescent flame-retardant technology, which is applied in the field of modified lignin intumescent flame-retardant TPO composite material and its preparation and application, can solve the problems of loose and porous charcoal thermal conductivity and high charcoal formation rate, and achieve weather resistance Good, high char formation rate, high tensile strength at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of modified lignin intumescent flame-retardant TPO composite material, the preparation method comprises the following steps:

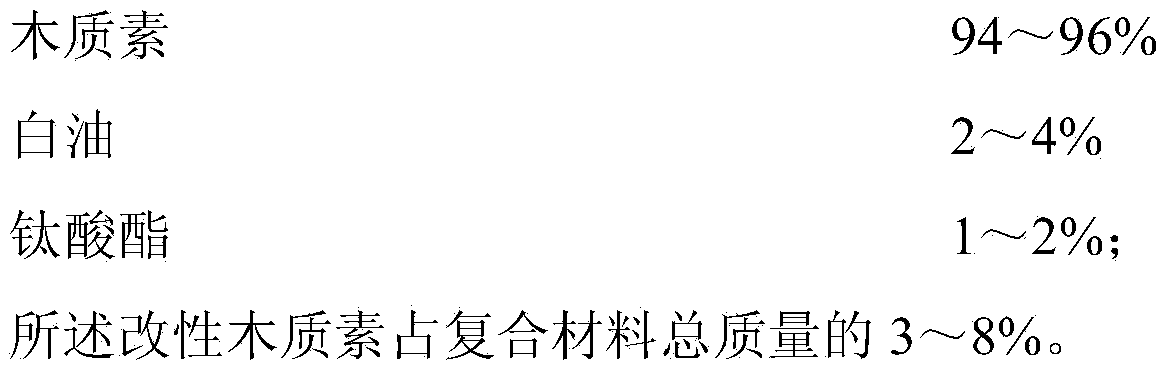

[0024] ①Add 96% lignin by mass to the high mixer, mix 2% white oil and 2% titanate by mass, and then add to the high mixer, and mix for 5 minutes to obtain modified wood white;

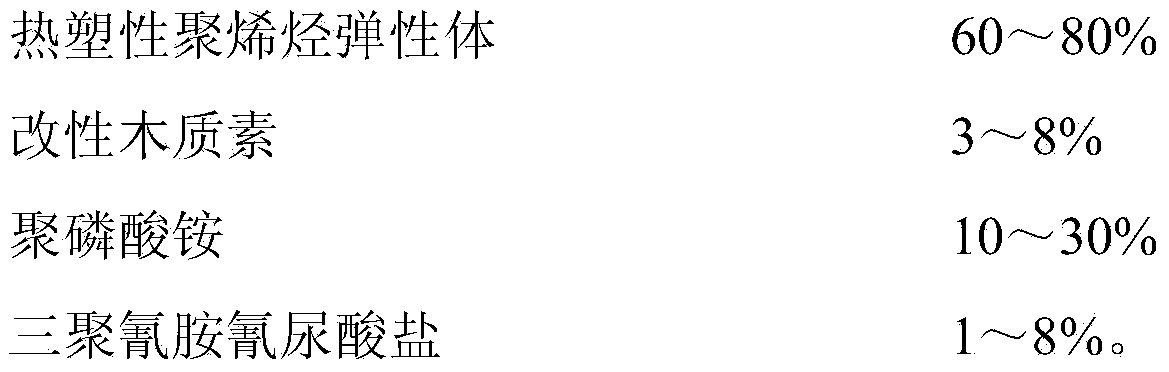

[0025] ②The thermoplastic polyolefin elastomer, modified lignin, ammonium polyphosphate and melamine cyanurate were vacuum-dried at 90°C for 4 hours. The thermoplastic polyolefin elastomer was a melt blend of polypropylene and EPDM rubber. , 70% by mass of thermoplastic polyolefin elastomer, 3% by mass of modified lignin, 21.3% by mass of ammonium polyphosphate and 5.7% by mass of melamine cyanurate in the open mill Kneading at 170°C for 10min, press molding at 175°C in a flat vulcanizer.

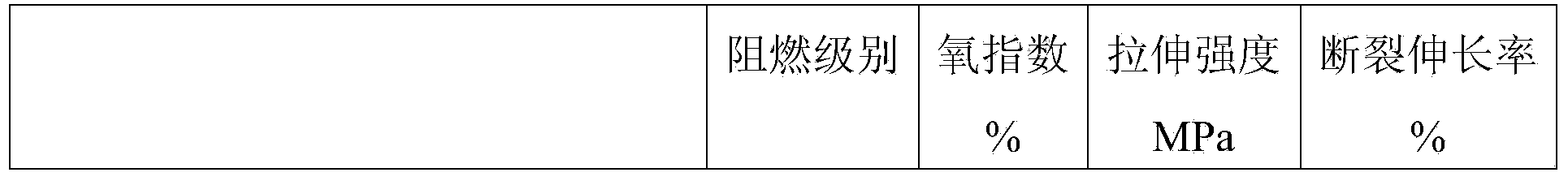

[0026] The performance evaluation and characterization results of the roofing waterproof composite material prepared in Example 1 are shown in Table 1.

Embodiment 2

[0028] The difference from Example 1 is:

[0029] The thermoplastic polyolefin elastomer, modified lignin, ammonium polyphosphate and melamine cyanurate were vacuum-dried at 90° C. for 4 hours. The thermoplastic polyolefin elastomer was a melt blend of polypropylene and EPDM rubber. 70% by mass of thermoplastic polyolefin elastomer, 4% by mass of modified lignin, 22.7% by mass of ammonium polyphosphate and 3.3% by mass of melamine cyanurate in open mill 170 Kneading for 10min, press molding at 175°C in a flat vulcanizer.

[0030] The performance evaluation and characterization results of the roofing waterproof composite material prepared in Example 2 are shown in Table 1.

Embodiment 3

[0032] The difference from Example 1 is:

[0033] The thermoplastic polyolefin elastomer, modified lignin, ammonium polyphosphate and melamine cyanurate were vacuum-dried at 90° C. for 4 hours. The thermoplastic polyolefin elastomer was a melt blend of polypropylene and EPDM rubber. 70% by mass of thermoplastic polyolefin elastomer, 5% by mass of modified lignin, 23.4% by mass of ammonium polyphosphate and 1.6% by mass of melamine cyanurate in open mill 170 Kneading for 10min, press molding at 175°C in a flat vulcanizer.

[0034] The performance evaluation and characterization results of the roofing waterproof composite material prepared in Example 3 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com