Titanium alloy laser-MIG composite welding method

A composite welding and titanium alloy technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of rare process research and application, high chemical activity of titanium alloy, and pollution in high-temperature welding areas, and achieve easy Automatic welding, good weld performance, and the effect of reducing the requirements for assembly conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

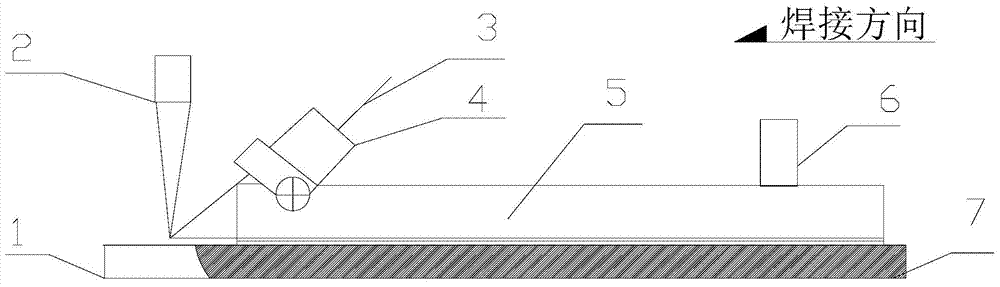

[0024] The laser used is the HL4006D Nd:YAG solid-state laser produced by TRUMFP in Germany, with a rated power of 4kW and a continuous wave laser with an output wavelength of 1.06μm, and a focusing lens with a focal length of 200mm; Binzel APDMFⅡ wire feeder.

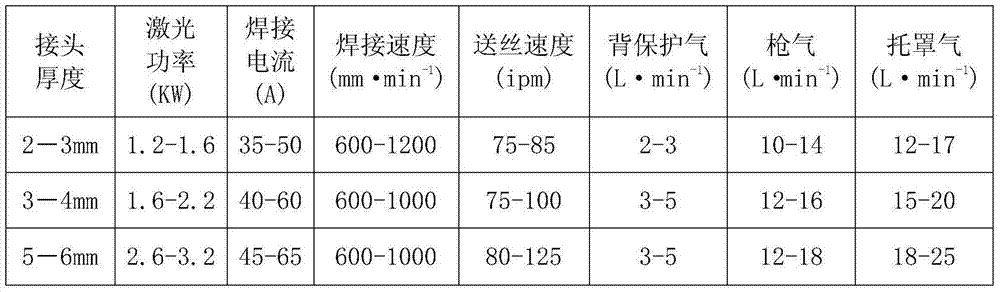

[0025] 1) TA12 titanium alloy material 6mm thick plate butt welding

[0026] The welding specifications are as follows: the groove type is type I; the welding wire is pure titanium welding wire with a diameter of 1.6mm; the distance between the light wires is 2mm, and the laser is in front; 60A, the shielding gas is 99.99% high-purity argon, the initial stage is YAG for 0.8s, MIG for 1s; the back shielding gas is 5L / min, the MIG gun gas is 18L / min, and the hood gas is 25L / min.

[0027] The titanium alloy flat plate butt weld obtained by the above-mentioned laser-MIG hybrid welding method has good shape, uniform corrugation, and good gas protection. There are no defects such as cracks, incomplete penetration and incom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com