9Cr13MoVCo stainless steel strip steel and preparation method thereof

A technology of stainless steel strip and molten steel is applied in the field of stainless steel materials to achieve the effect of improving quenching hardness, excellent wear resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

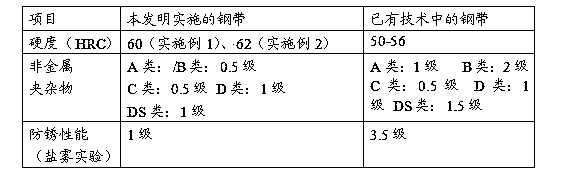

Examples

Embodiment 1

[0027] Take the preparation of 9Cr13MoVCo stainless steel hot-rolled strip steel with a width of 250mm and a thickness of 18mm as an example:

[0028] A) Smelting, adding high-carbon martensitic stainless steel, carbon steel waste and accurately calculated related ferroalloys to the intermediate frequency furnace for preliminary smelting according to different periods to obtain primary molten steel. Sampling and analyzing the initial molten steel and adjusting the mass % content of chemical elements in the initial molten steel: 0.88% carbon, 0.56% silicon, 37% manganese, 0.015% phosphorus, 0.007% sulfur, 13.22% Chromium, 0.20% molybdenum and 0.15% vanadium, 0.30% cobalt, and the remainder is iron. After the above-mentioned samples are analyzed and the mass % content of the chemical elements is adjusted, the slag is removed and reduced to obtain qualified components, slag white, The primary molten steel with good fluidity should be controlled at 1617°C; after that, the primary ...

Embodiment 2

[0036] Take the preparation of 9Cr13MoVCo stainless steel strip with a width of 250mm and a thickness of 4.0mm as an example:

[0037] A) Smelting, putting mold steel scrap, carbon steel scrap and ferroalloy into the intermediate frequency furnace for primary smelting to obtain primary molten steel, sampling and analyzing the primary molten steel and adjusting the mass % content of chemical elements in the primary molten steel to: 0.90% carbon, 0.46% silicon, 40% manganese, 0.013% phosphorus, 0.005% sulfur, 13.45% chromium, 0.25% molybdenum and 0.10% vanadium, 0.25% cobalt, and the rest is iron. After the above-mentioned sampling analysis and adjustment of the mass % content of chemical elements, slag removal and reduction are carried out to obtain a primary molten steel with qualified components, slag white, and good fluidity. The temperature of the primary molten steel is controlled at 1615°C; after that Put the initial molten steel into the LF furnace ladle for LF furnace r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com