Method for preparing itaconic acids copolyester with macromolecular network structure

A technology of network structure and copolyester is applied in the field of preparation of itaconic acid copolyester with macromolecular network structure, which can solve the problems of insufficient thermodynamic properties, reduced crystallization ability, disrupted molecular chain regularity, etc. Achieve the effect of improving mechanical properties and thermodynamic properties, easy operation and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

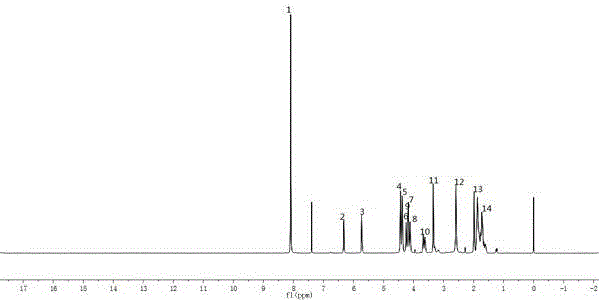

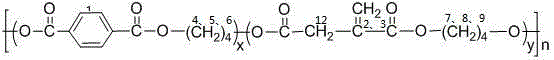

Image

Examples

Embodiment 1

[0025] The preparation method of the itaconic acid copolyester of macromolecular network structure described in the present embodiment comprises the following steps:

[0026] 1. Put terephthalic acid (0.02mol), dimethyl itaconate (0.18mol) and 1,4-butanediol (0.2mol) at a molar ratio of 1:9 in a 100ml flask, add esterification The catalyst tetrabutyl titanate is added in an amount of 0.1% of the total molar weight of the copolymerization system. Connect the water separator, thermometer and stirrer, raise the temperature to 150°C under the protection of nitrogen, and vigorously stir the reaction for 2~5 hours. When no more water is generated in the water separator, the prepolymerization stage ends, and the polyester prepolymer is obtained. .

[0027] 2. Heat up the polyester prepolymer obtained in step 1 to 180°C, depressurize to 50Pa to carry out polycondensation reaction, stir and react for 2 hours to remove small molecules, and obtain copolyester (polybutylene terephthalate...

Embodiment 2

[0030] The preparation method of the itaconic acid copolyester of macromolecular network structure described in the present embodiment comprises the following steps:

[0031] 1. Put terephthalate (0.18mol), dimethyl itaconate (0.02mol) and 1,4-butanediol (0.3mol) at a molar ratio of 9:1 in a 100ml flask, add The esterification catalyst tetrabutyl titanate is added in an amount of 3% of the total molar weight of the copolymerization system. Connect the water separator, thermometer and stirrer, raise the temperature to 190°C under the protection of nitrogen, and vigorously stir the reaction for 2~5 hours. When no more water is generated in the water separator, the prepolymerization stage ends, and the polyester prepolymer is obtained. .

[0032] 2. Heat up the polyester prepolymer obtained in step 1 to 230° C., reduce the pressure to 50 Pa to carry out polycondensation reaction, and stir for 6 hours to remove small molecules to obtain copolyester.

[0033] 3. After cooling, ad...

Embodiment 3

[0035] The preparation method of the itaconic acid copolyester of macromolecular network structure described in the present embodiment comprises the following steps:

[0036] 1. Put terephthalic acid (0.06mol), dimethyl itaconate (0.14mol) and 1,4-butanediol (0.26mol) at a molar ratio of 3:7 in a 100ml flask, add esterification The catalyst is antimony trioxide, and its addition amount is 1% of the total molar weight of the copolymerization system. Connect the water separator, thermometer and stirrer, raise the temperature to 160°C under the protection of nitrogen, and vigorously stir the reaction for 2~5 hours. When there is no more water in the water separator, the prepolymerization reaction stage ends, and the polyester prepolymer is obtained. .

[0037] 2. Heat up the polyester prepolymer obtained in step 1 to 200° C., reduce the pressure to 50 Pa to carry out polycondensation reaction, and stir for 3 hours to remove small molecules to obtain copolyester.

[0038] 3. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com