Solvent-free film-coating controlled-release fertilizer and preparation method thereof

A controlled-release fertilizer and solvent-free technology, applied in the direction of fertilizer forms, fertilizer mixtures, nitrogen fertilizers, etc., can solve the problems of uneven distribution of coating liquid, achieve the effects of shortening coating time, ensuring controlled-release performance, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1, preparation coated controlled-release fertilizer

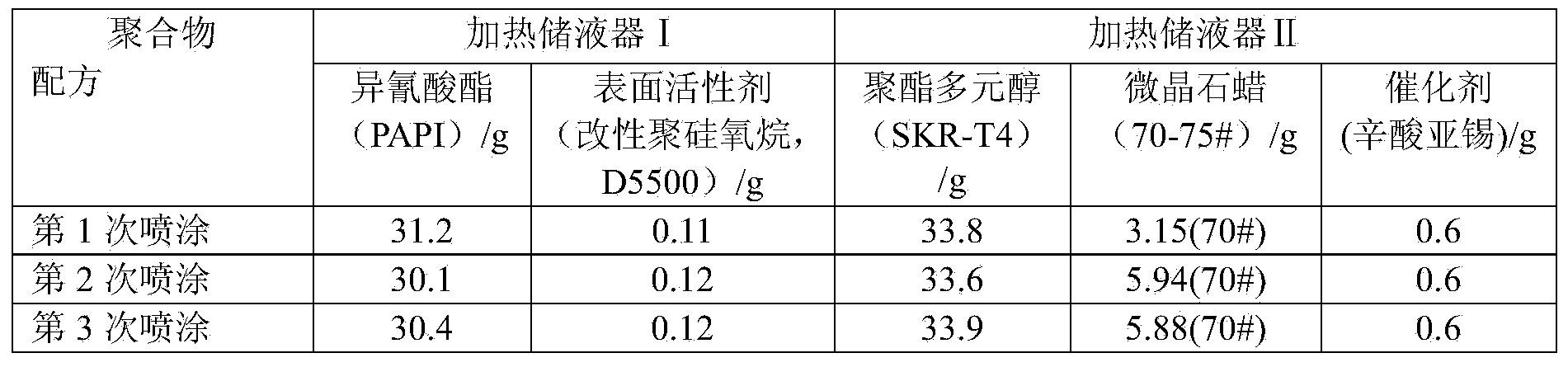

[0063] The formula table of this embodiment is shown in Table 1.

[0064] Table 1 Coating polymer formula table

[0065]

[0066] (1) Weigh 3kg of 2-3mm large grain urea for later use. Weigh 31.2 grams of diphenylmethane polyisocyanate (PAPI, Bayer company), put it in the heating liquid reservoir I8 and raise the temperature to 75 ° C, drop in 0.11 g of surfactant, stir well and keep warm at 75 ° C; at the same time, weigh the polyester Put 33.8g of polyol in another heating reservoir Ⅱ3, weigh 3.15g of microcrystalline paraffin wax (melting point 70°C, commercially available), put it into the heating reservoir Ⅱ3 and raise the temperature to 85°C, keep warm and stir, The microcrystalline paraffin wax is evenly dispersed in the polyol solution, and finally 0.6 g of the catalyst is added dropwise and continued to stir evenly.

[0067] (2) While the temperature of the two solutions is rising, continue ...

Embodiment 2

[0073] Embodiment 2, preparation coated controlled-release fertilizer

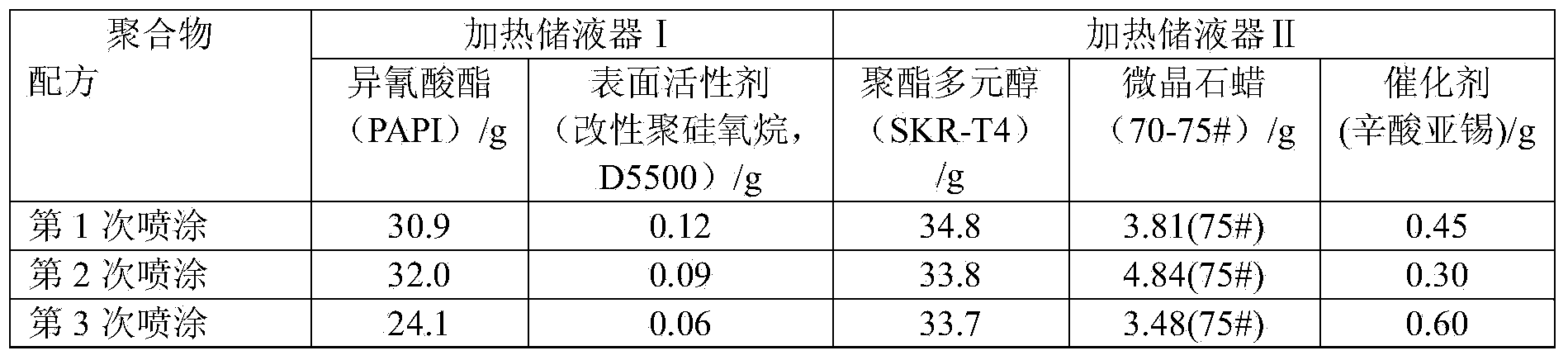

[0074] The formula table of this embodiment is shown in Table 2.

[0075] Table 2 Coating polymer formula table

[0076]

[0077](1) Weigh 3kg of 3-4mm large grain urea for use. Weigh 30.9 grams of polyisocyanate (PAPI, Bayer company), place it in the heating reservoir I8 and raise the temperature to 80°C, drop in 0.12g of surfactant, stir evenly and keep warm at 80°C; at the same time, weigh 34.8g of polyester polyol , put it in the heating reservoir Ⅱ3, weigh 3.81g of microcrystalline paraffin wax (melting point 75°C, commercially available), put it into the heating reservoir Ⅱ3 and raise the temperature to 95°C, keep warm and stir to make the microcrystalline paraffin evenly Disperse in the polyol solution, and finally add 0.45 g of the catalyst dropwise and continue to stir evenly.

[0078] (2) While the temperature of the two solutions is rising, continue to prepare the coating solution for the ...

Embodiment 3

[0082] Embodiment 3, preparation coated controlled-release fertilizer

[0083] The formula table of this embodiment is shown in Table 3.

[0084] Table 3 Coating polymer formula table

[0085]

[0086] (1) Weigh 2~3mm compound fertilizer (N:P 2 o 5 :K 2 O=15:15:15, mass ratio) 5kg spare. The first spraying solution is 40.0g of PAPI, 0.2g of surfactant is added to the heating reservoir Ⅰ8, stirred and heated to 85°C, 60.8g of polyol, 4.67g of microcrystalline paraffin wax 70# (melting point 70°C) and 0.67g of catalyst , added to the heating reservoir II3, stirred and heated to 90 ° C for later use. According to the formula shown in Table 3, add the 2 materials required for secondary spraying into the heating reservoir I8, stir and heat to 80°C, add the corresponding 3 materials in Table 3 into the heating reservoir II3, stir and heat to 90°C, according to the above method, weigh the materials required for the third time in Table 3 and add them to the corresponding heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com