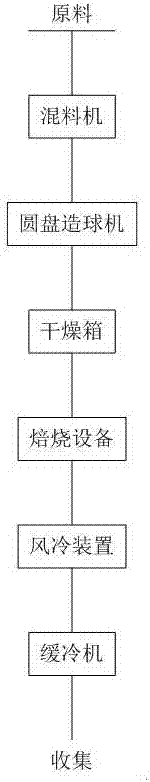

Device system for producing sintering-expanded haydite by red mud

A roasting device and ceramsite technology, which is applied in the production of ceramic materials, ceramic products, ceramic molding machines, etc., can solve the problems of inability to swell the ceramsite and insufficient gas generation, and achieve the goal of reducing the adhesion rate, saving resources and saving energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 40 parts of sintering red mud, 30 parts of fly ash powder, 15 parts of coal gangue, 10 parts of clay, and 5 parts of blue carbon powder were dried and ball milled, and passed through a 200-mesh square hole sieve, and pelletized on a disc. Spray water in the machine to make 8-12mm ceramsite wet pellets, put the ceramsite wet pellets into the drying box for drying, the drying temperature is 105°C, and dry for 24 hours. After drying, the ceramsite pellets are placed Put it into the muffle furnace for roasting, the roasting system is the highest temperature of 1200°C, roasting for 30min. After firing, it is rapidly cooled to below 400°C. The produced ceramsite meets the requirements of the national standard GB / T1743.1-2010 and can be used as a light aggregate for concrete.

Embodiment 2

[0053] 60 parts of Bayer red mud, 20 parts of fly ash powder, 10 parts of coal gangue, 5 parts of blue carbon powder, and 5 parts of clay were dried and ball-milled respectively, and all passed through a 200-mesh square hole sieve in a disc pelletizer Spray water in the medium to make 10-15mm ceramsite wet pellets, put the ceramsite wet pellets into the drying box for drying, the drying temperature is 105°C, and dry for 24 hours. The dried ceramsite pellets are sent to Roasting in the grate machine, the roasting system is the highest temperature of 1250 ° C, roasting 15min. After firing, it is rapidly cooled to below 400°C. The produced ceramsite meets the requirements of the national standard GB / T1743.1-2010 and can be used as a light aggregate for concrete.

Embodiment 3

[0055] Dry 50 parts of Bayer red mud, 25 parts of fly ash powder, 10 parts of coal gangue, 10 parts of blue carbon powder, and 5 parts of clay, respectively, after drying and ball milling, pass through a 200-mesh square hole sieve, and put them in a disc pelletizer Spray water in the medium to make 12-15mm ceramsite wet pellets, put the ceramsite wet pellets into the drying box for drying, the drying temperature is 105°C, and dry for 24 hours. The dried ceramsite pellets are sent to Roasting in a rotary hearth furnace, the roasting system is the highest temperature of 1150 ° C, roasting 20min. After firing, it is rapidly cooled to below 400°C. The produced ceramsite meets the requirements of the national standard GB / T1743.1-2010 and can be used as a light aggregate for concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com