Pack rolling production method of titanium steel composite board

A production method and composite plate technology, applied in the direction of metal rolling, etc., can solve the problems of small environmental pollution production specifications and product specifications, and achieve the effects of controllable product specifications, controllable production scale, and overcoming large environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

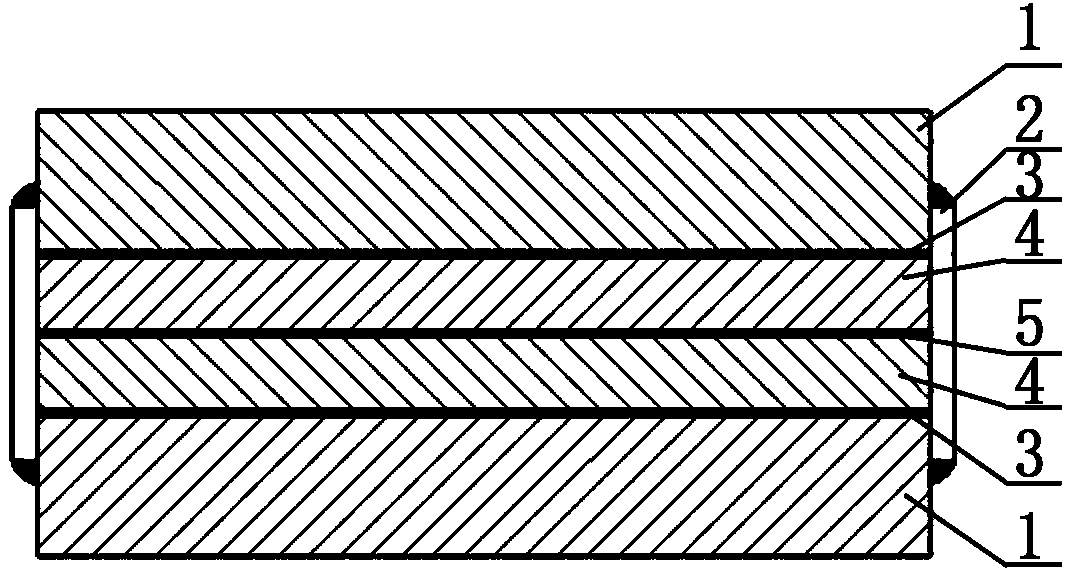

[0026] according to Figure 1~2 The composite slab structure and production method of the present invention are described in detail. The stack rolling production method of the titanium-steel clad plate includes the following steps: material selection-surface treatment-billet assembly (sealed and welded periphery-inlaid welded conduit-air tightness inspection-vacuumizing)-slab heating-rolling (hot rolling) - heat treatment diffusion welding - surface cleaning - leveling - annealing - trimming.

[0027] It mainly involves the following equipment: shearing machine, grinding machine, hot rolling mill, heating furnace, acid-base washing tank, air pump, hydraulic press, argon arc welding machine, vacuum pump, burner.

[0028] Specifically, it includes the following steps:

[0029] 1) Select the plate materials of cladding plate 4 (titanium plate of the present invention), substrate 1 (steel plate of the present invention), and transition layer 3 (pure iron plate of the present inv...

Embodiment 2

[0039] The thickness ratio of the titanium plate to the steel plate is 1.5:10; the release agent is a mixture of magnesium oxide powder and talcum powder with a weight ratio of 1.0:0.6. Other steps are with embodiment 1.

Embodiment 3

[0041] The thickness ratio of the titanium plate to the steel plate is 1.2:10; the release agent is a mixture of magnesium oxide powder and talcum powder with a weight ratio of 1.0:1.6. Other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com