Selective ITO (tin indium oxide) etching solution

A technology of indium tin oxide and indium tin oxide film, applied in the direction of surface etching composition, chemical instrument and method, can solve the problems of corrosion of ITO copper film, poor effect, slow etching rate, etc., and achieve complete etching and etching. Fast and effective rate, uniform etching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0030] Add 450g of hydrochloric acid with a mass concentration of 36% (including 162g of hydrochloric acid), 30g of acetic acid, 10g of hexamethylenediamine, and 10.01g of Rongqiang HA-110.01g, add deionized water to make 1000g of etching solution, and spray and etch at 40°C for 120 seconds. Among them, Rongqiang HA-11 is fatty alcohol polyoxyethylene polyoxypropylene ether compound. Compare and test the line resistance before and after etching, take the resistance between two points on different non-film-covered lines as the initial value for many times, and the etching is completed when the resistance is infinite. The resulting circuit diagram is as figure 1 shown.

specific Embodiment 2

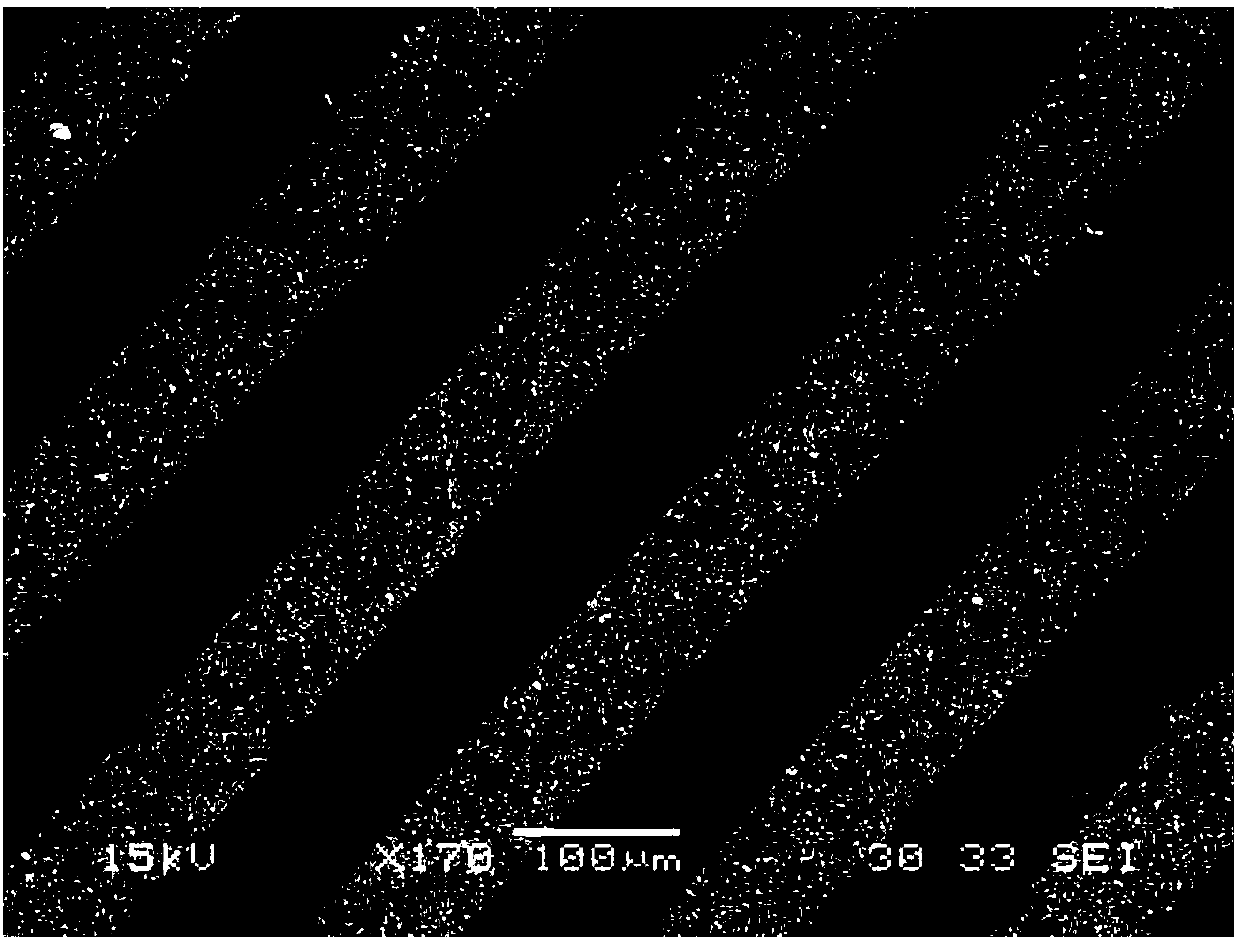

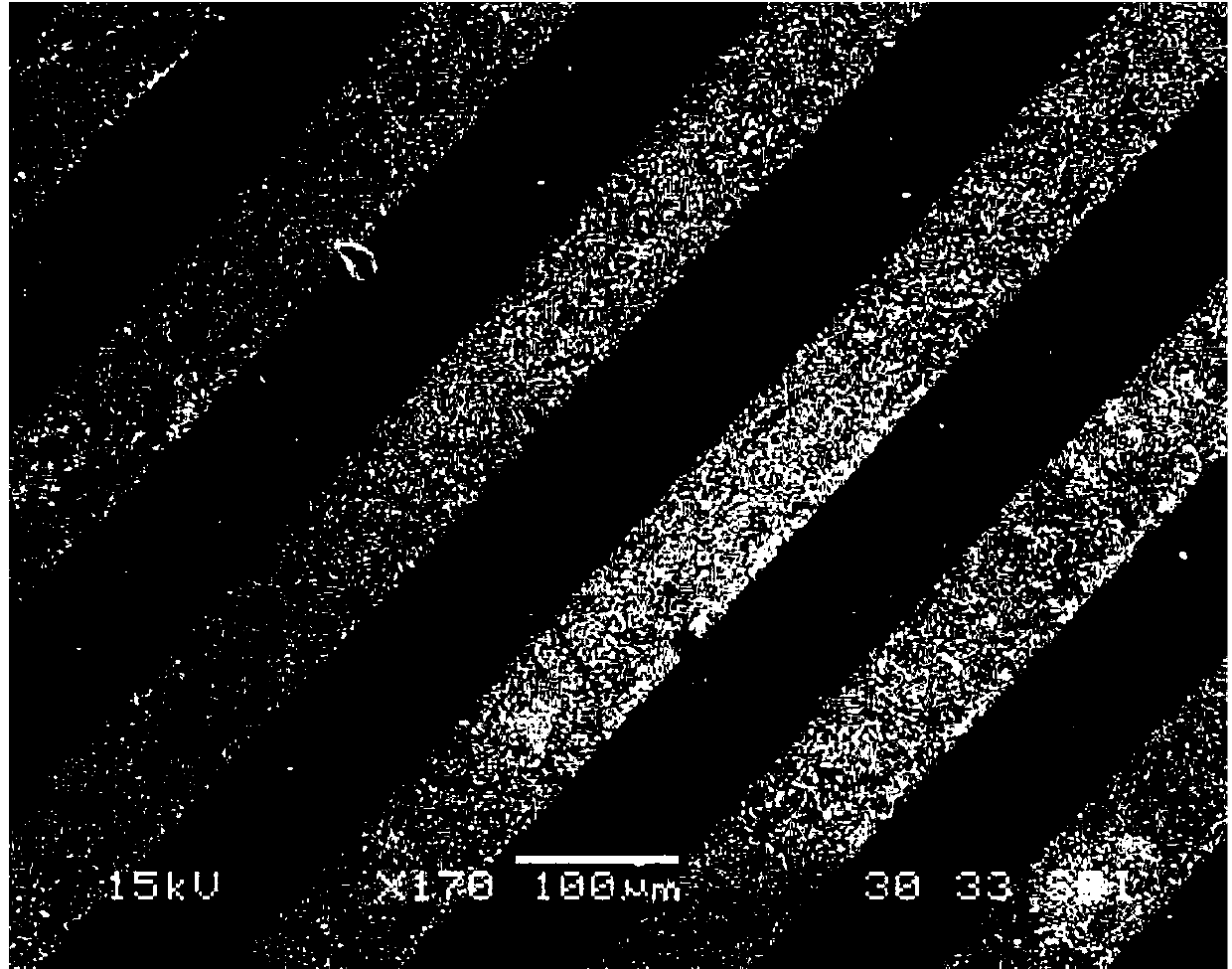

[0031] Add 600g of hydrochloric acid with a mass concentration of 36% (including 216g of hydrochloric acid), 30g of acetic acid, 20g of 2-hexylbenzimidazole, and 160.1g of Rongqiang RQ-160.1g, add deionized water to make 1000g of etching solution, and spray etch at 40°C 120 seconds and 20 minutes. Wherein RQ-16 is fatty alcohol ether nonionic surfactant polymer. Compare and test the line resistance before and after etching, take the resistance between two points on different non-film-covered lines as the initial value for many times, and the etching is completed when the resistance is infinite. The resulting circuit diagram is as figure 2 with image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com