Tempering low-emissivity coated glass containing silver alloy

A low-emissivity coating and silver alloy technology, applied in the direction of glass/slag layered products, metal layered products, chemical instruments and methods, etc., can solve problems such as oxidation or corrosion, soft silver film, and reduced optical and electrical properties , to meet the needs of color, improve the processing resistance, enhance the effect of oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

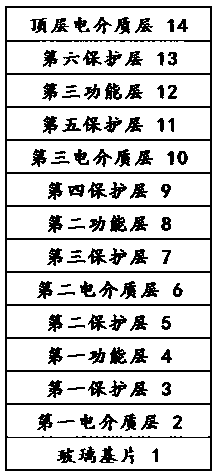

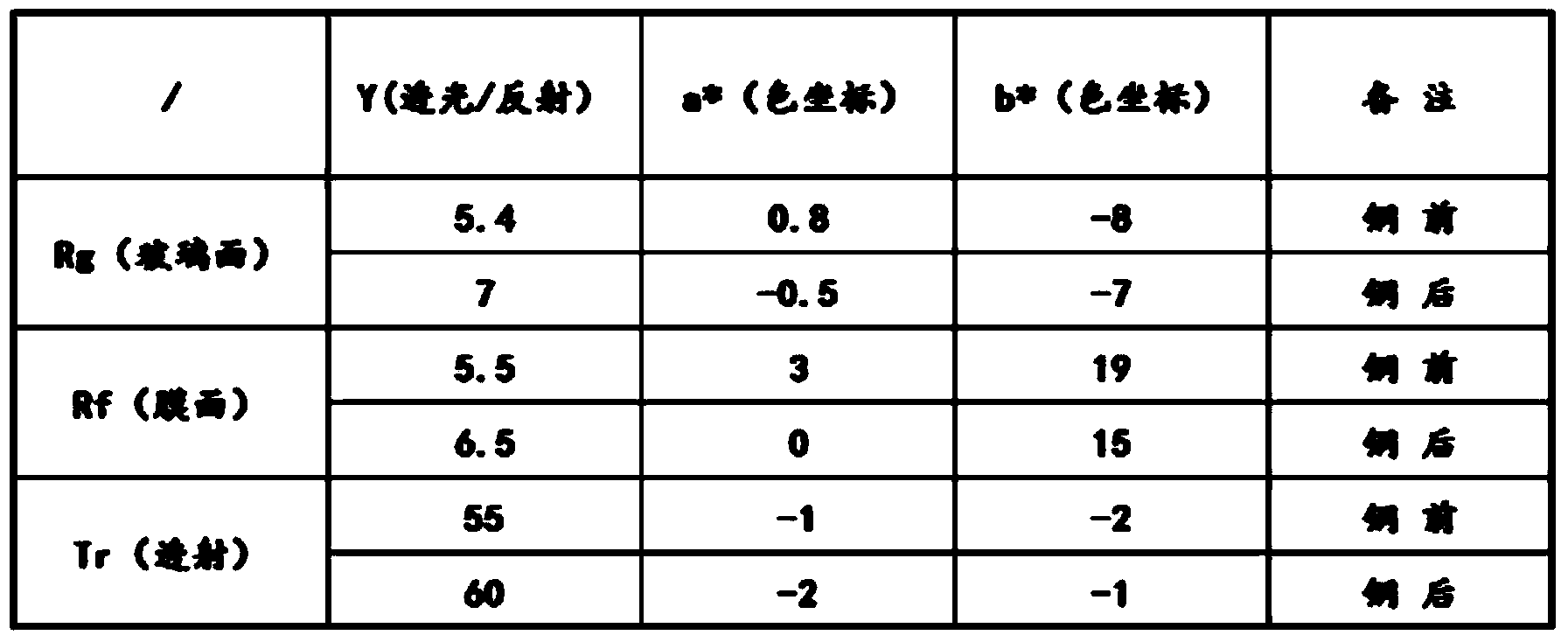

[0033] In this embodiment, the specific film structure is:

[0034] Glass / Si 3 N 4 / AZO / NiCr / Ag-Cu-Ni / NiCr / AZO / ZnSnO3 / AZO / NiCr / Ag / NiCr / AZO / ZnSnO3 / AZONiCr / Ag / NiCr / AZO / Si 3 N 4

[0035] In this embodiment, the first dielectric layer 2 and the top dielectric layer 14 are Si 3 N 4 The combination layer of AZO and AZO has a film thickness range of 25-100nm.

[0036]In this embodiment, the first, second, third, fourth, fifth, and sixth protective layers are NiCr layers, and the film thickness range is 1-20 nm.

[0037] In this embodiment, the second and third dielectric layers 6 and 10 are combined layers of AZO, ZnSnO3 and AZO, and the film thickness range is 10-80nm.

[0038] In this embodiment, the first functional layer 4 is an Ag-Cu-Ni alloy, wherein the mass ratio of Ag is 90%, the mass ratio of Cu is 8%, and the mass ratio of Ni is 2%. That is, Ag-Cu-Ni=90:8:2; the second and third functional layers 8 and 12 are Ag layers, and the film thickness range is 5-30nm.

[0...

no. 2 example

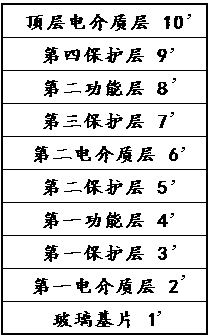

[0044] In this embodiment, the specific film structure is:

[0045] Glass / Si 3 N 4 / AZO / NiCr / Ag / NiCr / AZO / ZnSnO3 / AZO / NiCr / Ag-Cu-Al / NiCr / AZO / ZnSnO3 / AZONiCr / Ag / NiCr / AZO / Si 3 N 4

[0046] In this embodiment, the first dielectric layer 2 and the top dielectric 14 are Si 3 N 4 The combination layer of AZO and AZO has a film thickness range of 30-80nm.

[0047] In this embodiment, the first, second, third, fourth, fifth, and sixth protective layers are NiCr layers, and the thickness of the film is in the range of 0.5-20 nm.

[0048] In this embodiment, the second and third dielectric layers 6 and 10 are combined layers of AZO, ZnSnO3 and AZO, and the film thickness range is 20-80nm.

[0049] In this embodiment, the second functional layer 8 is an Ag-Cu-Al alloy, wherein Ag accounts for 90%, Cu accounts for 5%, and Al accounts for 5%. That is, Ag-Cu-Ni=90:5:5. The first and third functional layers 4 and 12 are Ag layers, and the film thickness range is 5-25nm.

[0050] The f...

no. 3 example

[0055] In this embodiment, the specific film structure is:

[0056] Glass / Si 3 N 4 / AZO / NiCr / Ag / NiCr / AZO / ZnSnO3 / AZO / NiCr / Ag / NiCr / AZO / ZnSnO3 / AZO / NiCr / Ag-Cu-Pt / NiCr / AZO / Si 3 N 4

[0057] In this embodiment, the first dielectric layer 2 and the top dielectric layer 14 are Si 3 N 4 The combination layer of AZO and AZO has a film thickness range of 15-120nm.

[0058] In this embodiment, the first, second, third, fourth, fifth, and sixth protective layers are NiCr, and the film thickness range thereof is 0.5-10 nm.

[0059] In this embodiment, the second and third dielectric layers 6 and 10 are combined layers of AZO, ZnSnO3 and AZO, and the film thickness range is 5-30 nm.

[0060] In this embodiment, the third functional layer 12 is an Ag-Cu-Pt alloy, wherein Ag accounts for 95%, Cu accounts for 4%, and Pt accounts for 1%. That is, Ag-Cu-Pt=95:4:1. The first and second functional layers 4 and 8 are Ag layers, and the film thickness range is 3-30nm.

[0061] The following...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com