Method for manufacturing fine-grain TA15 titanium alloy sheet for superplastic forming

A superplastic forming and titanium alloy technology, applied in metal rolling, temperature control and other directions, can solve the problems of difficult operability, complicated procedures and increased workload, and achieve simplified procedures, good hardenability, and reduced work. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

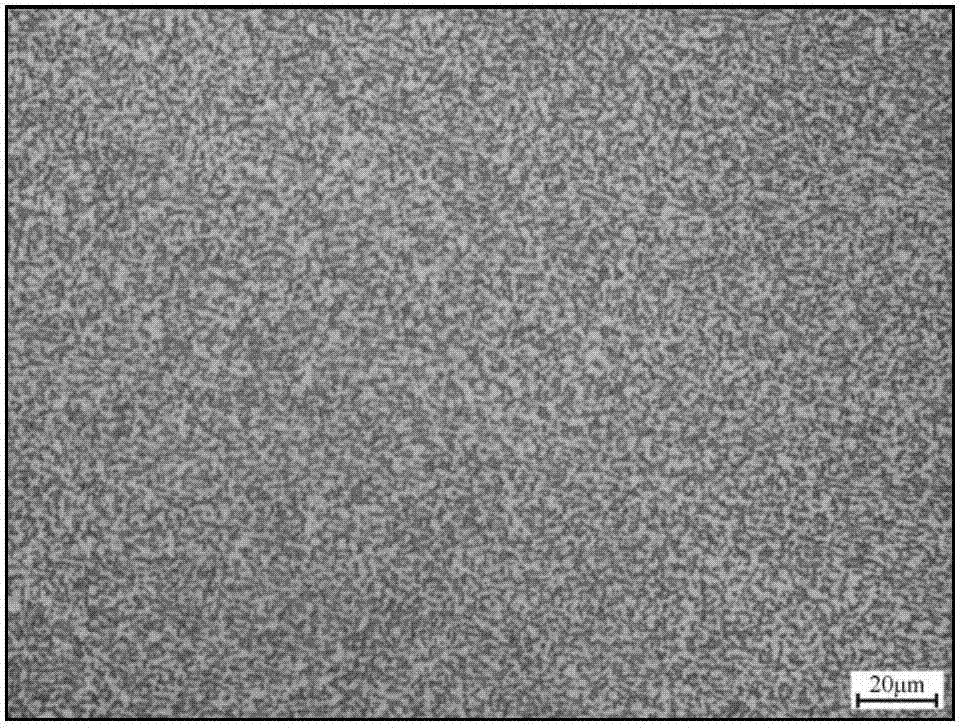

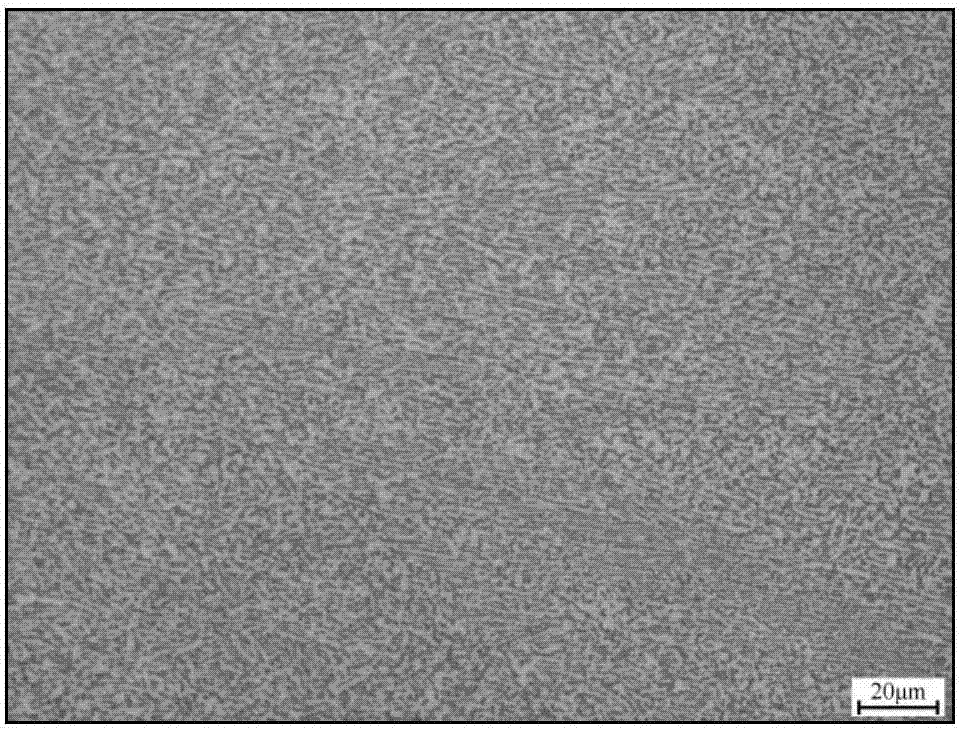

Image

Examples

Embodiment 1

[0033] Preparation of fine-grained TA15 titanium alloy sheet with a thickness of 0.6 mm for superplastic forming:

[0034] Step 1. Select a TA15 titanium alloy slab with a thickness of 120mm. After passing the external dimension and internal flaw detection inspection, it is sent to a 2800mm four-roll reversing hot rolling mill. The initial rolling temperature is 10°C above the β transformation point, and the final Under the condition that the rolling temperature is 10°C below the β transformation point, the first rolling of 6 passes is carried out, and the processing ratios of each pass are: 10%, 18%, 23%, 26%, 28%, 17%, and then The upper and lower surfaces of the TA15 titanium alloy slab after the first rolling are sprayed repeatedly at the same time to rapidly water-cool to room temperature at a cooling rate of not less than 10°C / s, and the first slab with a thickness of 30mm is obtained after surface grinding. Half finished board;

[0035] Step 2. Send the first semi-fini...

Embodiment 2

[0040] Preparation of fine-grained TA15 titanium alloy sheet with a thickness of 0.8 mm for superplastic forming:

[0041] Step 1. Select a TA15 titanium alloy slab with a thickness of 150mm. After passing the appearance size and internal flaw detection inspection, it is sent to a 2800mm four-roll reversing hot rolling mill. The initial rolling temperature is 10°C above the β transformation point, and the final Under the condition that the rolling temperature is 15°C below the β transformation point, the first rolling of 7 passes is carried out, and the processing ratios of each pass are: 10.5%, 20%, 25%, 28%, 20%, 9%, 5% %, then the upper and lower surfaces of the TA15 titanium alloy slab after the first rolling are sprayed repeatedly at the same time to make it rapidly water-cooled to room temperature at a cooling rate of not less than 10°C / s, and the thickness is obtained after surface grinding. 40mm first semi-finished sheet;

[0042] Step 2. Send the first semi-finished ...

Embodiment 3

[0047] Preparation of fine-grained TA15 titanium alloy sheet with a thickness of 1.0 mm for superplastic forming:

[0048] Step 1. Select a TA15 titanium alloy slab with a thickness of 180mm. After passing the external dimension and internal flaw detection inspection, it is sent to a 2800mm four-roll reversing hot rolling mill. The initial rolling temperature is 12°C above the β transformation point, and the final Under the condition that the rolling temperature is 12°C below the β transformation point, the first rolling of 8 passes is carried out, and the processing ratios of each pass are: 8.5%, 15%, 21.5%, 28%, 21.5%, 19.2%, 5.5% %, 5%, and then repeatedly spray the upper and lower surfaces of the TA15 titanium alloy slab after the first rolling to make it rapidly water-cooled to room temperature at a cooling rate of not less than 10°C / s, and after surface grinding Obtain the first semi-finished sheet material that thickness is 45mm;

[0049] Step 2. Send the first semi-fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com