Harmful-substance processing material, its manufacturing method and harmful-substance processing method

A technology for harmful substances and treatment methods, applied in separation methods, water/sewage treatment, chemical instruments and methods, etc., which can solve the problems of reduced adsorption capacity, high price, and less satisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

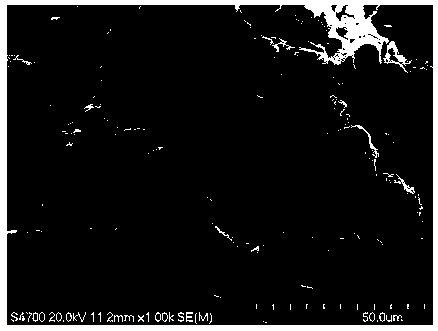

Image

Examples

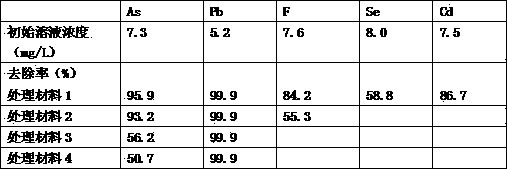

Embodiment 1

[0049] Active porous calcium silicate particles, using a commercially available lightweight air cell concrete board (manufactured by Clion Co., Ltd., SiO 2 : 49.5%, CaO: 35.3%, Al 2 o 3 : 4.4%, Fe 2 o 3 : 2.6%. SiO 2 / CaO ratio = 1.4) After drying and crushing, adjust to calcium silicate particles with a particle diameter of 1.2 mm or less and 0.1 mm or more. In addition, commercially available light calcined magnesia (manufactured by Ube Material Co., Ltd.) was used as a magnesium raw material, and commercially available aluminum sulfate powder (trade name: aluminum sulfate) was used as a pH adjuster.

[0050] Using a mixing mixer, stir and mix 40 weight units of calcium silicate particles, 30 weight units of light calcined magnesium oxide, 10 weight units of aluminum sulfate and 8 weight units of water at room temperature for 5 minutes, and then put them in a closed container It was allowed to stand still for 12 hours to undergo a hydration reaction to obtain a pow...

Embodiment 2

[0054] Using the same calcium silicate particles, magnesium raw materials, and aluminum sulfate as in Example 1, 10 weight units of calcium silicate particles, 3 weight units of light calcined magnesia, 1 weight unit of aluminum sulfate and 2 weight units were mixed with a mixing mixer. A unit of water was stirred and mixed at room temperature for 5 minutes, then placed in a closed container and left to stand for 12 hours for hydration reaction to obtain a powdery reactant (processing material 2) with an average particle size of 0.3 mm and a volume ratio of 0.76. The chemical composition of the powder reactant is SiO 2 : 21.3%, Al 2 o 3 : 2.4%, CaO: 16.5%, MgO: 35.8%, Fe 2 o 3 : 1.6%, SO 3 : 7.5%, moisture: 14.3%. In addition, after pulverizing the powdery reactant and analyzing it with an X-ray powder analyzer, it was found that there were peaks in the reaction including magnesium oxide, magnesium hydroxide, gypsum dihydrate, calcium silicate hydrate, silicon dioxide, an...

Embodiment 3

[0056] Using the same method as in Example 1, the commercially available lightweight cellular concrete slabs were pulverized and adjusted to calcium silicate particles with a particle size of 4.0-1.2 mm. And use the same magnesium raw material and aluminum sulfate as in Example 1.

[0057] Using a mixing mixer, stir and mix 4 weight units of porous calcium silicate, 3 weight units of light calcined magnesia, 1 weight unit of aluminum sulfate and 3 weight units of water at room temperature for 2 minutes, and then put them into an airtight container The mixture was allowed to stand in the middle for 12 hours to undergo a hydration reaction to obtain a granular reactant (processing material 3) with an average particle diameter of 4 mm and a volume ratio of 0.91. The chemical composition of the granular reactant is SiO 2 : 20.4%, Al 2 o 3 : 5.1%, CaO: 16.0%, MgO: 39.6%, Fe 2 o 3 : 1.8%, SO 3 : 16.7%, moisture: 25.2%. In addition, when the granular reactant was pulverized an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com