Manganite epitaxial thin film and preparation method thereof

A technology of manganese oxide and epitaxial thin film, which is applied in the field of material science, can solve problems such as cracks on the surface of the thin film, and achieve the effects of small roughness, good giant magnetoresistance effect, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 manganese oxide epitaxial film

[0030] A. Preparation of precursor solution

[0031] Weigh 0.00525mol of lanthanum acetate, 0.00225mol of strontium acetate and 0.0075mol of manganese acetate, add 40ml of acetic acid and 10ml of water, heat to reflux to dissolve the solute completely, and obtain a transparent orange-yellow solution; Microporous membrane filtration to obtain stable lanthanum strontium manganese oxide (La 0.7 Sr 0.3 MnO 3 ) precursor solution;

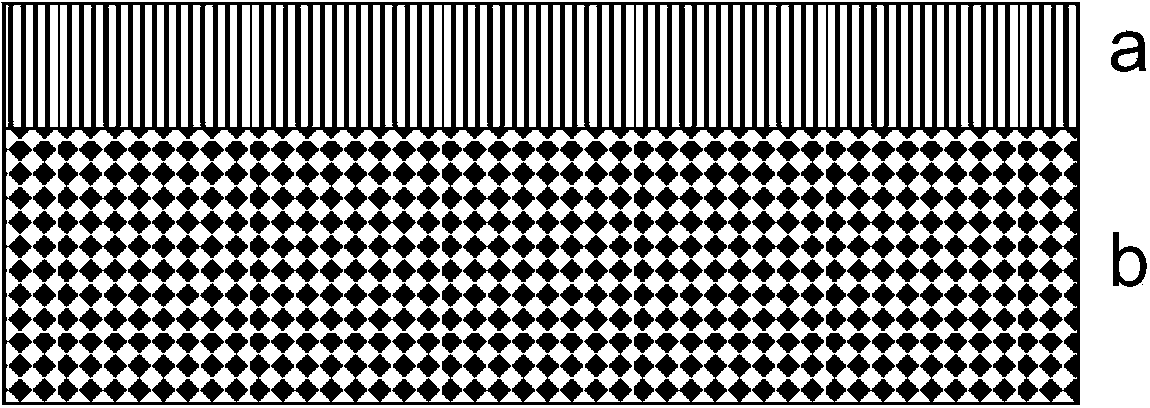

[0032] B. Preparation of epitaxial thin film

[0033] Add the prepared LSMO precursor solution dropwise to the cleaned SrTiO 3 On the substrate, three kinds of sample substrate crystal orientations (100), (110), (111), the rotation speed of the substrate is 5000 rpm, and keep for 30 seconds to obtain a layer of lanthanum strontium manganese oxide gel film; In an annealing furnace, heat at 200°C for 3 minutes, then pyrolyze at 400°C for 3 minutes, and finally anneal at 800°C for ...

Embodiment 2

[0034] Performance characterization of embodiment 2 manganese oxide epitaxial film

[0035] Various properties of the manganese oxide epitaxial film prepared in Example 1, ie, the LSMO film, were tested.

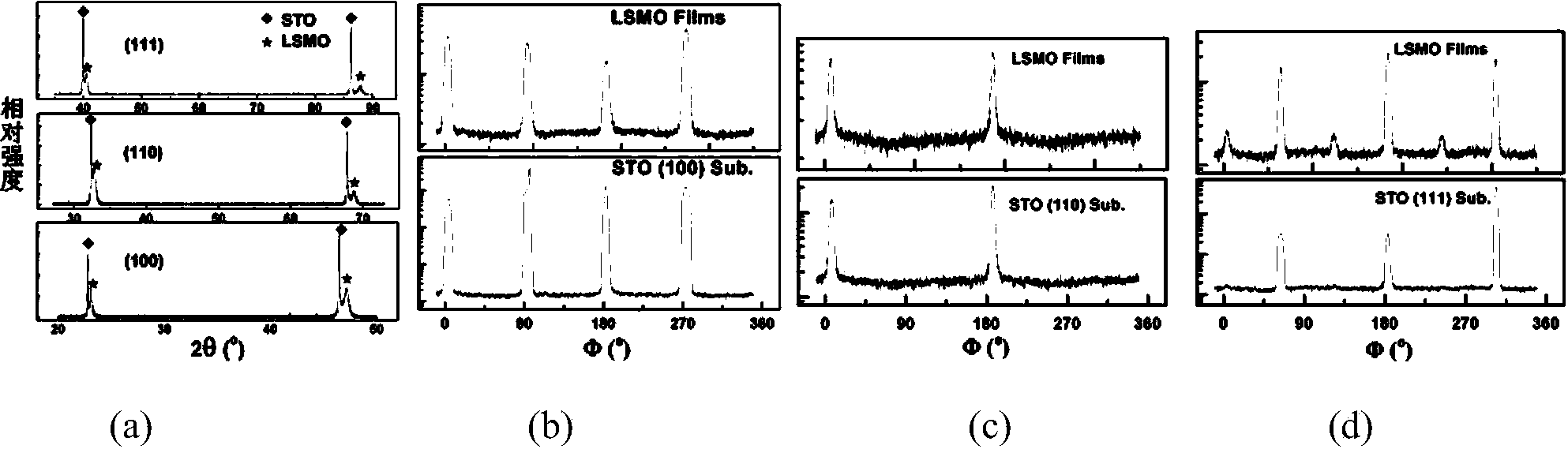

[0036] (1) Microstructure

[0037] X-ray diffraction is the diffraction effect caused by the interference of X-rays incident into the sample and the crystal lattice, and is used to characterize the crystallization properties of materials. 2θ~ω scanning is a typical scanning method of high-resolution scanning, which can remove the influence of the oblique section of the substrate on the test results; Φ scanning reflects the symmetry of the crystal in the horizontal direction, and then characterizes its epitaxy degree. The X-ray diffractometer used in this embodiment is the D8Discover high-resolution diffractometer of Bruker Company. The working voltage and current are 40kV×40mA, and the incident X-rays are Kα radiation produced by Cu targets, with a wavelength of 0.15406nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com