Preparation method of room temperature sulfurated silicon rubber material co-enhanced by lignin and white black carbon

A technology of room temperature vulcanization and white carbon black, which is applied in the field of rubber materials to achieve the effects of cost reduction, simple process and remarkable reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

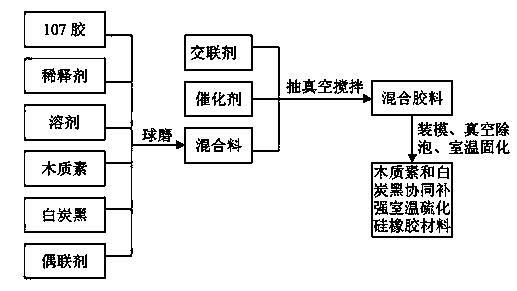

Method used

Image

Examples

Embodiment 1

[0010] (1) Lignin purification: 100 g of wheat straw enzymatic lignin residue was added to 500 ml of 12% NaOH solution under continuous stirring and boiled for 2 h, and then the insoluble matter was removed by hot filtration. After the filtrate was cooled to room temperature, the pH value was adjusted to 7 with 1 mol / L of HCl, and lignin was precipitated after standing, and purified such as figure 1 lignin in

[0011] (2) Preparation of room temperature vulcanized silicone rubber material synergistically reinforced by lignin and silica: 100 g of 107 glue with a viscosity of 10000 cp, 5 g of methyl silicone oil, 80 g of n-hexane, 2 g of lignin, and 10 g of silica Mix with 0.1 g of coupling agent KH560 in a high-energy ball mill for 2 h at high speed, add 0.1 g of diisobutyltin dilaurate and 5 g of tetraethoxysilane, stir in vacuum for 10 min, pour into a mold for vacuum defoaming Cured at room temperature for 24 hours, cut into dumbbell-shaped samples for tensile performance t...

Embodiment 2

[0013] (1) lignin purification and modification are the same as in Example 1;

[0014] (2) Preparation of lignin-reinforced room temperature vulcanized silicone rubber material: 100 g of 107 glue with a viscosity of 10000 cp, 5 g of methyl silicone oil, 100 g of n-hexane, 4 g of lignin, 10 g of white carbon black and 0.1 g of dioxane The joint agent KH560 was ball-milled at a high speed in a high-energy ball mill for 2 hours, then 0.2 g of diisobutyltin dilaurate and 5 g of tetraethoxysilane were added, stirred in a vacuum for 10 minutes, poured into a mold for vacuum defoaming, and cured at room temperature for 24 hours , cut into dumbbell-shaped samples according to GB / T528-1998 for tensile performance test, the tensile strength is 0.48 MPa, the elongation at break is 54%, compared with pure room temperature vulcanized silicone rubber, respectively increased by 71% and decreased by 24% (corresponding The tensile strength test value of the blank sample of pure room temperatur...

Embodiment 3

[0016] (1) lignin purification and modification are the same as in Example 1;

[0017] (2) Preparation of lignin-reinforced RTV silicone rubber material: 100 g of 107 glue with a viscosity of 10000 cp, 5 g of methyl silicone oil, 100 g of n-hexane, 2 g of lignin, 8 g of white carbon black and 0.1 g of The joint agent KH560 was ball-milled at a high speed in a high-energy ball mill for 2 hours, then 0.2 g of diisobutyltin dilaurate and 5 g of tetraethoxysilane were added, stirred in a vacuum for 10 minutes, poured into a mold for vacuum defoaming, and cured at room temperature for 24 hours , cut into dumbbell-shaped samples according to GB / T528-1998 for tensile performance testing, the tensile strength is 0.72 MPa, and the elongation at break is 73%, which are respectively increased by 157% and 9% compared with pure room temperature vulcanized silicone rubber (corresponding The tensile strength test value of the blank sample of pure room temperature vulcanized silicone rubber w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com