Strengthening method of surface of piercing plug of seamless steel tube rolling mill

A technology of seamless steel pipe and perforated plug, which is applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of affecting service life, short service life, wear and scrap, etc., to ensure metallurgical bonding and low welding temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

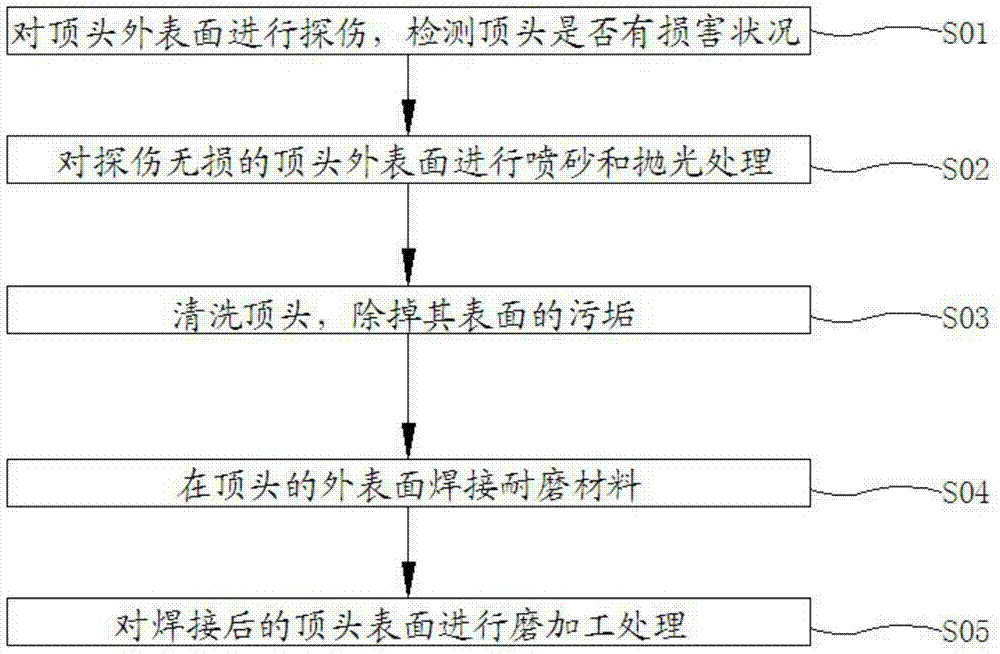

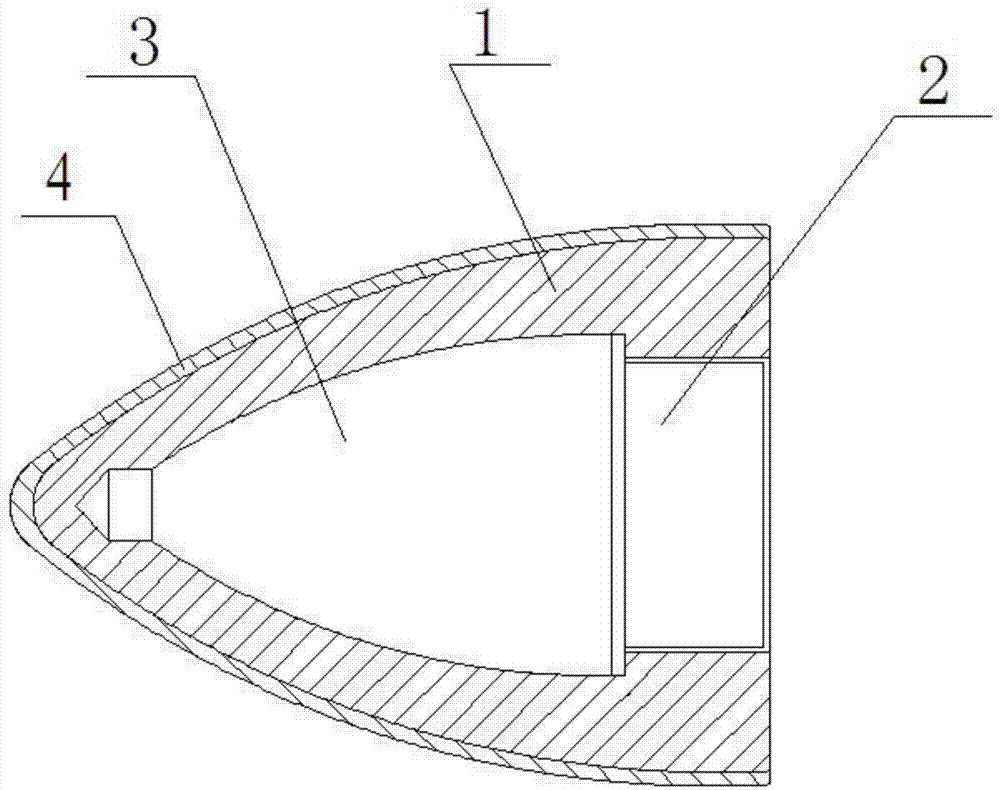

[0021] A method for strengthening the surface of a seamless steel pipe mill piercing plug according to the present invention is characterized in that it includes the following steps: Step 1 S01, inspecting the outer surface of the plug to detect whether the plug is damaged; Step 2 S02, non-destructive to the flaw detection The outer surface of the plug is subjected to sand blasting and polishing; Step 3 S03, cleaning the plug after sand blasting and polishing to remove the dirt on the surface; Step 4 S04, welding wear-resistant on the outer surface of the plug that has been removed from the dirt layer; Step 5 S05, grinding the welded plug surface, the welding material welded in the step 4 S04 is cobalt-based hard all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com