Carbon fiber impregnating adhesive and preparation method thereof

A technology of impregnating glue and carbon fiber, which is applied in the field of construction material preparation, can solve the problems of low viscosity of carbon fiber impregnating glue, shedding of carbon fiber sheets, poor bonding performance, etc., and achieve excellent physical and mechanical properties, enhanced bonding performance, Excellent wettability and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

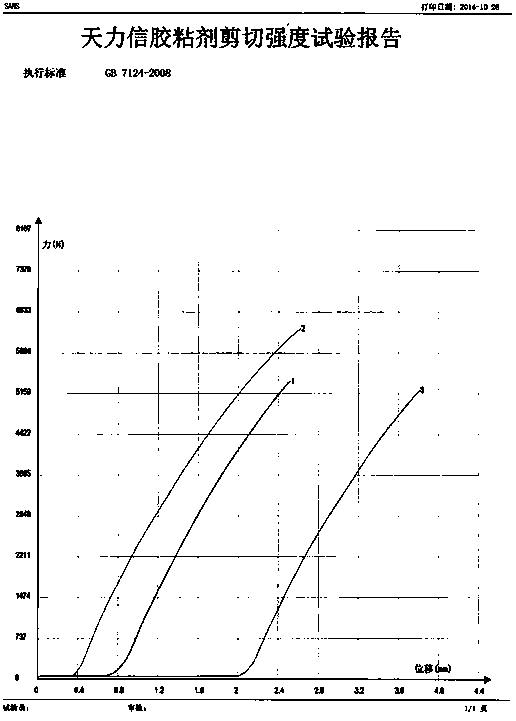

Image

Examples

Embodiment 1

[0024] A carbon fiber impregnated glue of the present invention is composed of component A and component B, wherein the mixing ratio of component A and component B by weight is 4:1, and component A by weight includes ring 90-110 parts of oxygen resin, 5-25 parts of diluent, 10-30 parts of toughening agent, 0.5-1.5 parts of defoamer, 2-6 parts of gas silicon, 6-26 parts of active calcium powder; the B component By weight, it includes 25-45 parts of curing agent, 1-5 parts of accelerator, 0.5-1.5 parts of coupling agent, and 0.125-0.75 parts of color paste; the total amount of the A component is 113.5-188.5 parts, and the B group The total amount of servings is 28.4-47.1 servings.

[0025] The preparation method of a kind of carbon fiber impregnated glue of the present invention comprises the following steps, step 1, A component is mixed, and the epoxy resin raw material after weighing and measuring, diluent raw material, toughening agent raw material, defoaming agent raw materi...

Embodiment 2

[0028] A carbon fiber impregnated glue of the present invention is composed of component A and component B, wherein the mixing ratio of component A and component B by weight is 4:1, and component A by weight includes ring 95 parts of epoxy resin, 10 parts of thinner, 15 parts of toughening agent, 1 part of defoamer, 3 parts of fumed silicon, 10 parts of active calcium powder; the B component includes 30 parts of curing agent, accelerator 2 parts, 1 part of coupling agent, 0.5 parts of color paste; the total amount of the A component is 134 parts, and the total amount of the B component is 33.5 parts.

[0029] The preparation method of a kind of carbon fiber impregnated glue of the present invention comprises the following steps, step 1, A component is mixed, and the epoxy resin raw material after weighing and measuring, diluent raw material, toughening agent raw material, defoaming agent raw material are added respectively High-speed dispersing kettle Ⅰ disperses and stirs. S...

Embodiment 3

[0032]A carbon fiber impregnated glue of the present invention is composed of component A and component B, wherein the mixing ratio of component A and component B by weight is 4:1, and component A by weight includes ring 100 parts of epoxy resin, 15 parts of diluent, 20 parts of toughening agent, 1 part of defoamer, 4 parts of gas silicon, 16 parts of active calcium powder; The B component includes 35 parts of curing agent, accelerator 2.5 parts, 1 part of coupling agent, and 0.5 parts of color paste; the total amount of the A component is 156 parts, and the total amount of the B component is 39 parts.

[0033] The preparation method of a kind of carbon fiber impregnated glue of the present invention comprises the following steps, step 1, A component is mixed, and the epoxy resin raw material after weighing and measuring, diluent raw material, toughening agent raw material, defoaming agent raw material are added respectively High-speed dispersing kettle Ⅰ disperses and stirs. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com