A wear-resistant surfacing alloy containing ceramic phases of mo and cr elements and its preparation process

A ceramic phase and alloy technology, applied in the field of material science, can solve the problems of increasing production costs, precious alloy elements, and non-appearance, and achieve the effects of increasing bonding strength, simplifying preparation methods, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The wear-resistant surfacing alloy of the ceramic phase containing Mo and Cr elements, according to the mass percentage of elements, Cr30%, Mo3%, Ni0.5%, C6%, the balance is iron element and other inevitable impurities.

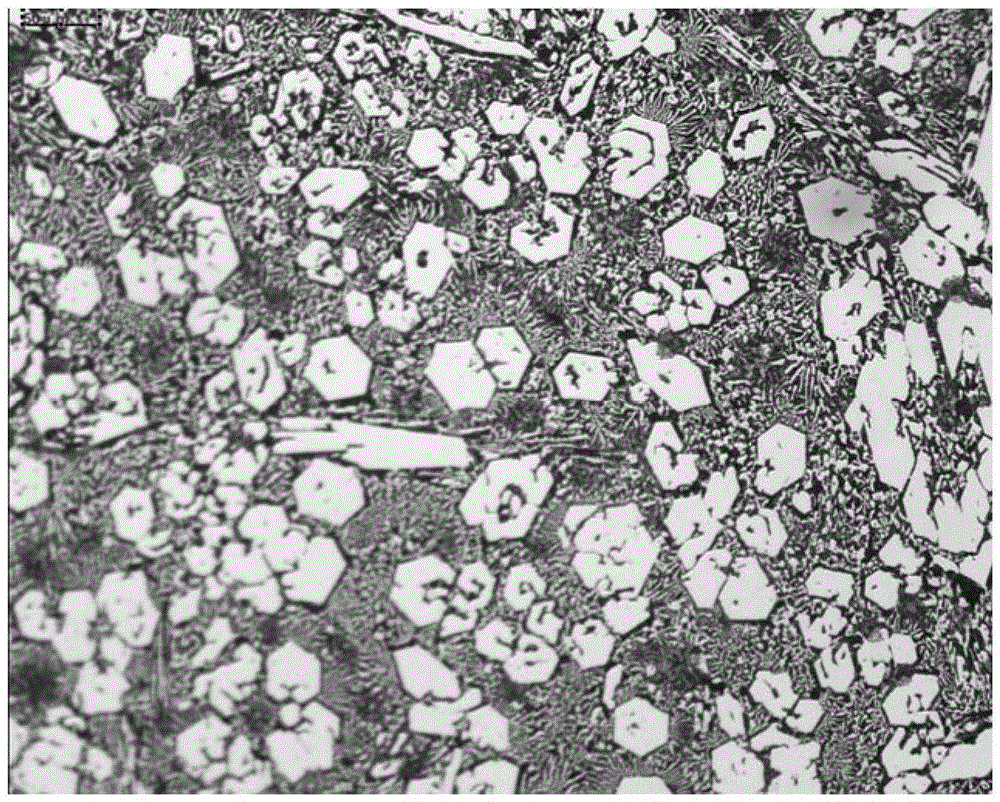

[0031] The above alloy system is used for plasma surfacing, and the hardness of the surfacing layer reaches 56-60HRC. The MMU-5G material end face high-temperature friction and wear tester is used for the pin wear test. The wear test parameters: speed 200r / min, test force 300N, wear time 5min, the test temperature is 500°C. The wear amount of the surfacing layer is 0.3317g, and the microstructure of the surfacing alloy is shown in figure 1 .

Embodiment 2

[0033] The wear-resistant surfacing alloy of the ceramic phase containing Mo and Cr elements, according to the mass percentage of elements, Cr25%, Mo4%, Ni0.8%, C7%, and the balance is iron and other inevitable impurities.

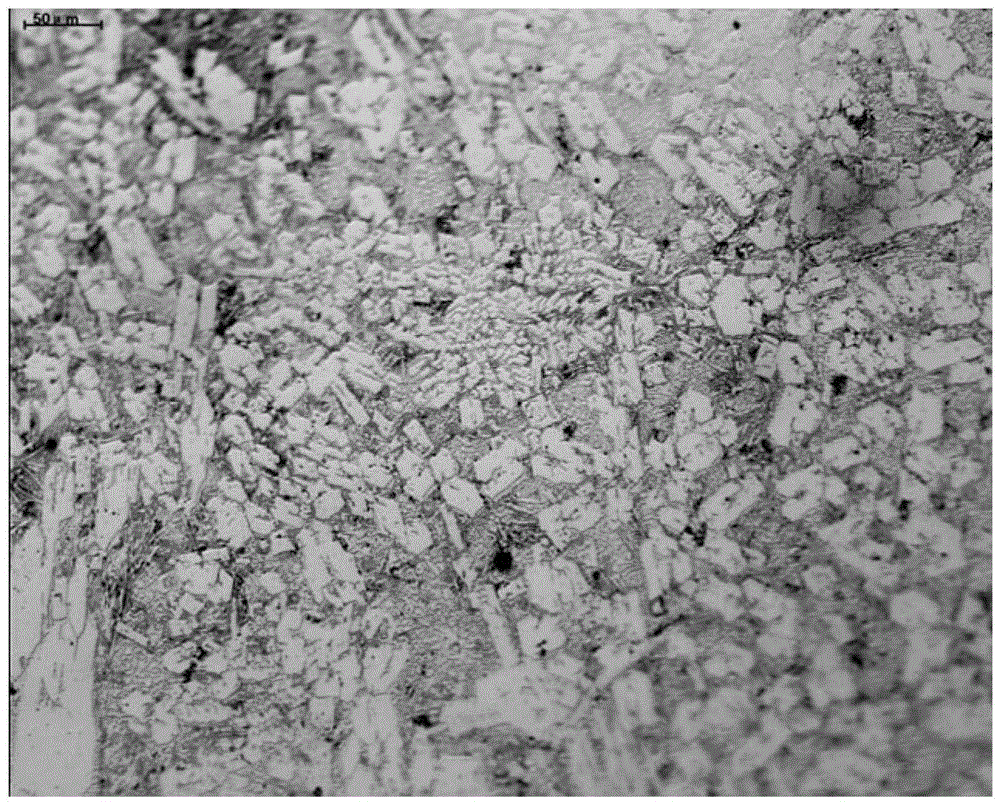

[0034] The above-mentioned alloy materials are used for plasma surfacing, and the hardness of the surfacing layer reaches 50-58HRC. The MMU-5G material end face high-temperature friction and wear testing machine is used for the pin wear test. The wear test parameters: speed 200r / min, test force 300N, wear The time is 5 minutes, and the test temperature is 500°C. The wear amount of the surfacing layer is 0.3929g, and the microstructure of the surfacing alloy is shown in figure 2 .

Embodiment 3

[0036] The wear-resistant surfacing alloy of the ceramic phase containing Mo and Cr elements, according to the mass percentage of elements, Cr20%, Mo5%, Ni1%, C8%, the balance is iron element and other inevitable impurities.

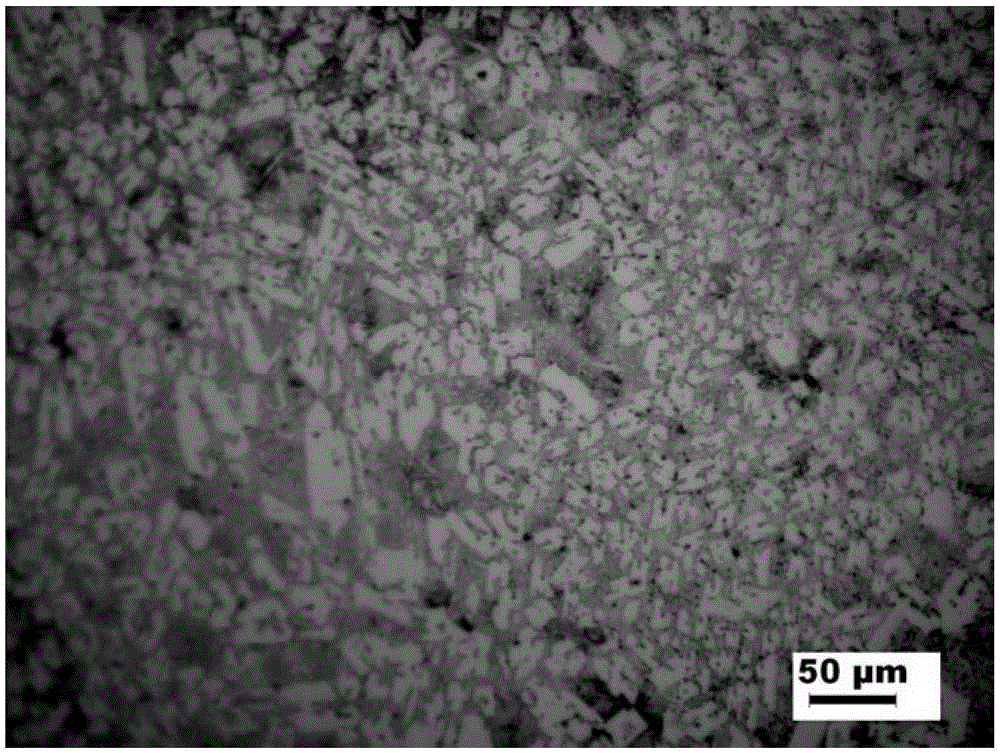

[0037]The above-mentioned alloy materials are used for plasma surfacing, and the hardness of the surfacing layer is 50-55HRC. The MMU-5G material end face high-temperature friction and wear testing machine is used for the pin wear test. The wear test parameters are rotation frequency 200r / min, test force 300N, The wear time is 5min, and the test temperature is 500°C. The wear amount of the surfacing layer is 0.2919g, and the microstructure of the surfacing alloy is shown in Fig. 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com