Catalyst module element for selective catalytic reduction, catalyst module using the element, and method for manufacturing the same

A catalyst module and selective technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, etc., can solve problems such as catalyst cracking, achieve simple manufacturing method, mobile The effect of excellent removal efficiency and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 6

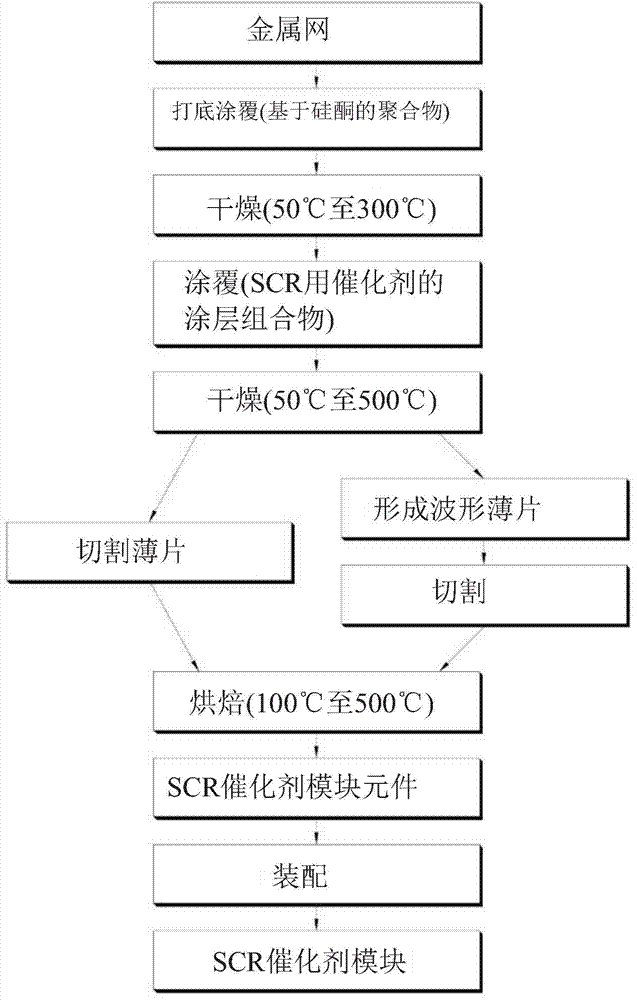

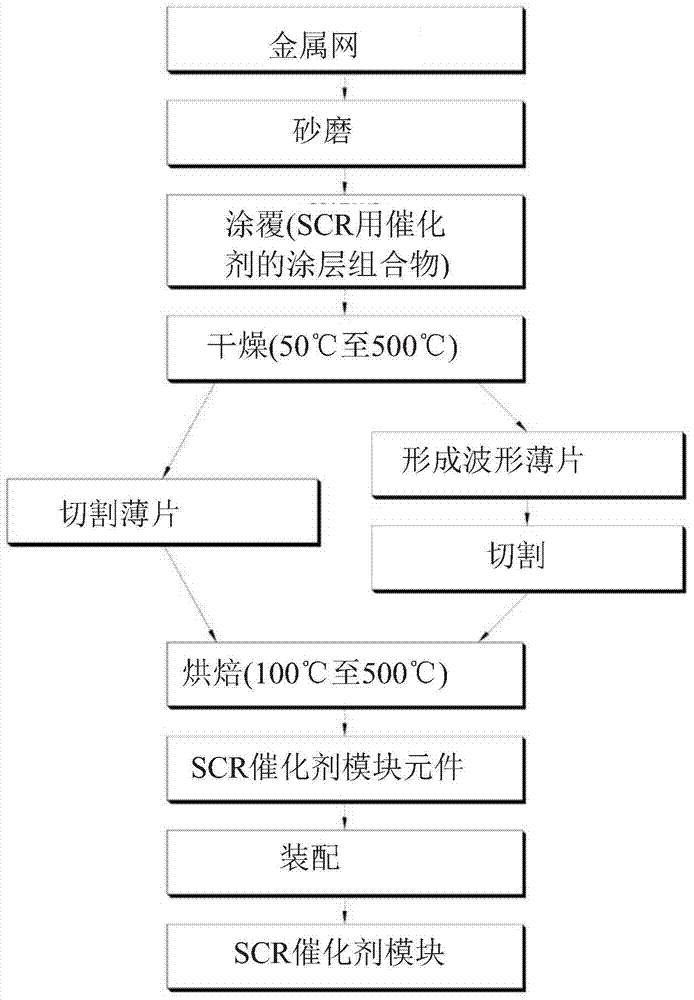

[0119] First, a metal mesh (3P, Hyugjae metal lath Co.) of STS304 stainless steel material with a thickness of 0.35 mm, a distance between wires of 3 mm, and a width of 450 mm was prepared.

[0120] The metal mesh was heat treated at 400° C. and treated with phosphoric acid to remove oil and contaminants so that the metal coating composition for SCR could adhere firmly to the metal mesh.

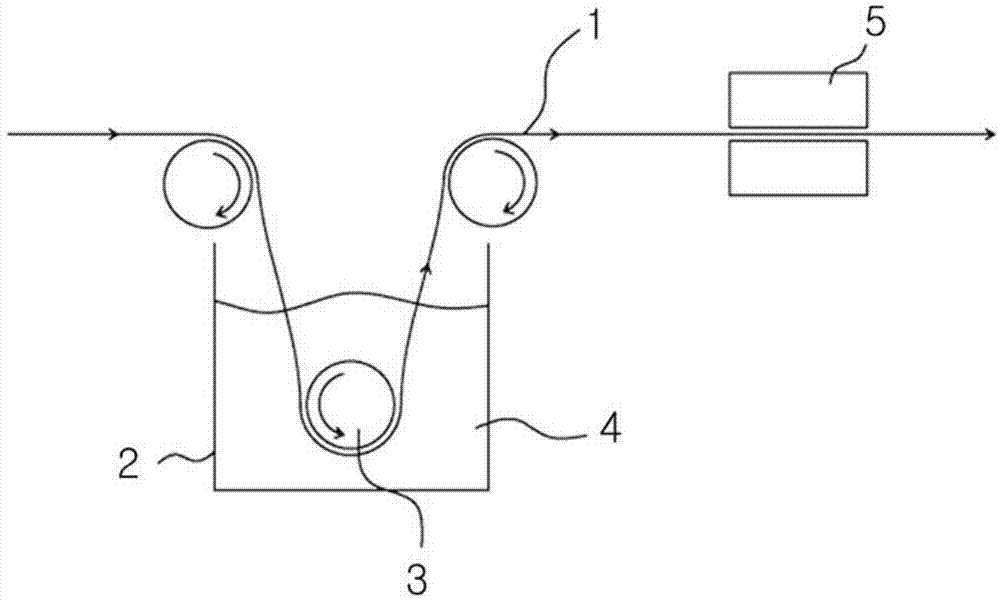

[0121] Sand the metal screen with alumina or silica. Separately, by mixing methyltrimethoxysilane with pH 4, water-dispersible silica (Ludox TM , DuPont) reaction to prepare a silicone-based polymer solution. The metal mesh was dipped into the silicone-based polymer solution to form an undercoat layer, and dried at 300° C. for 1 hour. In this case, the average thickness of the dried coating was 10 μm.

[0122]Thereafter, by adding silicone-based polymer, silicon-based ceramic powder or glass fiber powder (Glassue TM , KumKang Fiber Industries), SCR catalyst powder (Daeyoung C&E Co., Ltd....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diagonal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com