CO boiler-flue gas denitration reactor integrated unit

A denitrification reactor and combined device technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as dust ingress, achieve the effects of reducing investment, ensuring thermal efficiency, and improving heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

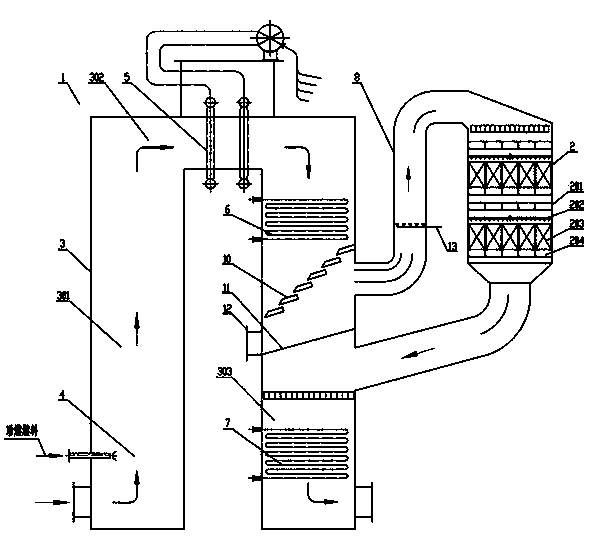

[0025] The specific scheme and usage of the denitration reactor of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] Depend on figure 1 As shown, the present invention provides a combined device of a CO boiler and a denitration reactor, the combined device includes a CO boiler 1 and a denitration reactor 2, the CO boiler 1 and the denitration reactor 2 are arranged side by side, and the CO boiler includes a flue 3 , combustion chamber 4, steam drum 5, evaporation section 6 and economizer section 7, the flue includes a first vertical flue 301, a horizontal flue 302 and a second vertical flue 303, the horizontal flue Both ends of the duct 302 communicate with the upper part of the first vertical flue 301 and the second vertical flue 303 respectively, the combustion chamber 4 is arranged in the first vertical flue 301, and the steam drum 5 is arranged in the horizontal flue 302 Inside, the evaporation section 6 and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com