Silicon-carbide-core nano compound particle coated by nitrogen-doped carbon shell and preparation method of particle

A carbon shell-coated silicon carbide and nanocomposite particle technology, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of mass production of limited materials, insufficient stability, and cumbersome synthesis methods and other problems, achieve high thermal stability and chemical stability, improve service life, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take 20mg of cubic silicon carbide particles with an average particle size of 60nm, put them into a crucible, add two drops of saturated nickel chloride solution, stir evenly and dry them, then add 200mg of melamine powder and mix evenly, put them in a vacuum furnace, and vacuum to 10 -3 Pa, heated to 1000°C for 3 hours, then cooled to room temperature while maintaining a vacuum environment. The obtained powder was soaked in concentrated hydrochloric acid with a concentration of 37% for 12 hours to remove metallic nickel, washed with deionized water until neutral and dried to obtain nitrogen-doped carbon shell-coated silicon carbide core nanocomposite particles.

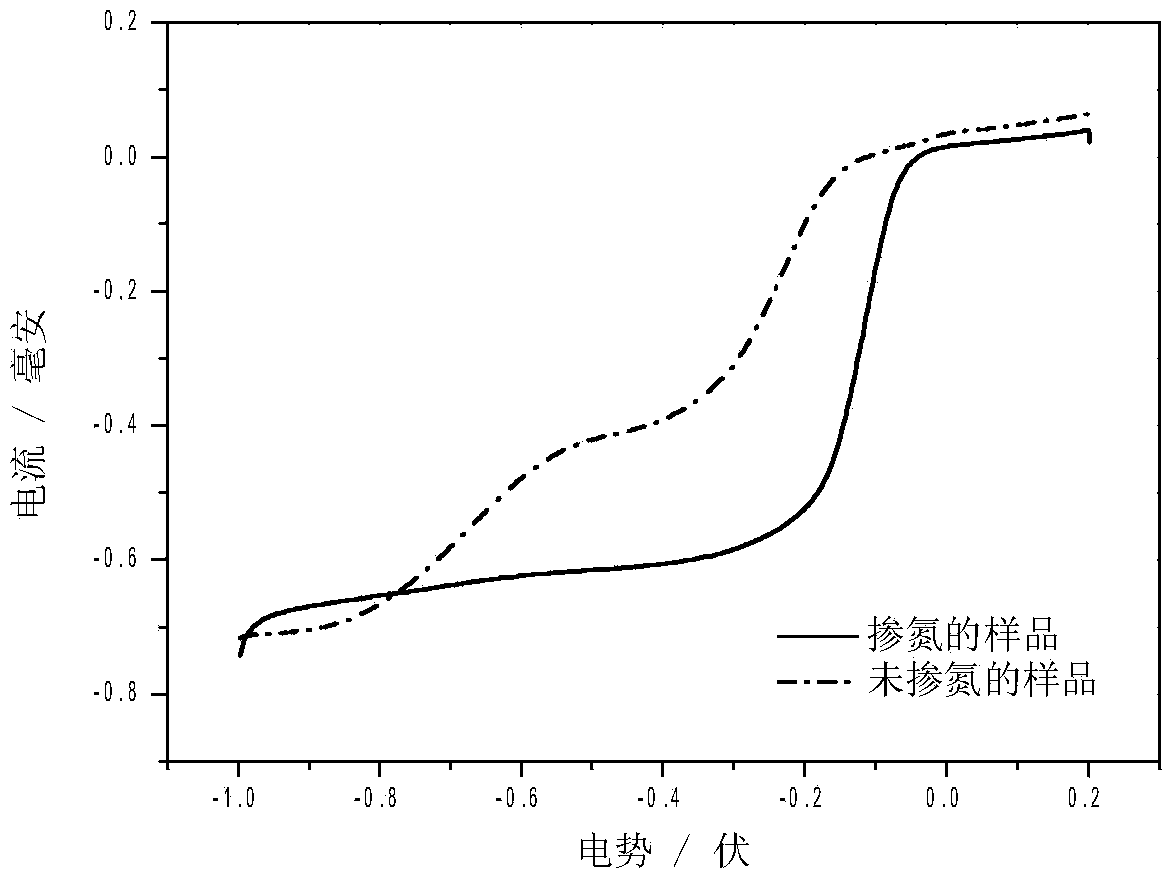

[0019] Such as figure 1 As shown, after vacuum heat treatment, a carbon layer is formed on the surface of nano-silicon carbide, and obvious defects can be observed in the carbon layer, which is caused by the introduction of nitrogen into the carbon layer.

[0020] Such as figure 2 As shown, peaks represent...

Embodiment 2

[0023] Take 20mg of silicon carbide whiskers with an average particle size of 100nm, put them into a crucible, add two drops of saturated nickel chloride solution, stir evenly, dry them, then put in 100mg of melamine powder and mix evenly, and vacuum to 10 -3 Pa filled with argon protection, heated to 1300 ° C for 2 hours, and cooled to room temperature under the condition of maintaining a vacuum environment. Soak the obtained powder with concentrated hydrochloric acid with a concentration of 37% for 14 hours to remove metallic nickel, wash with deionized water until neutral and dry to obtain nitrogen-doped carbon shell-coated silicon carbide core nanocomposite particles.

Embodiment 3

[0025] Take 20 mg of cubic silicon carbide particles with an average particle size of 180 nm, put them into a crucible, add two drops of saturated nickel chloride solution, stir evenly, and dry them, then add 100 mg of melamine powder and mix evenly, put them in a vacuum furnace, and pump Vacuum to 10 -3 Pa filled with nitrogen protection, heated to 1500 ° C for 0.5 hours, and cooled to room temperature under the condition of maintaining a vacuum environment. Soak the obtained powder with concentrated hydrochloric acid with a concentration of 37% for 13 hours to remove metallic nickel, wash with deionized water until neutral and dry to obtain nitrogen-doped carbon shell-coated silicon carbide core nanocomposite particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com