A kind of preparation method of high molecular weight fluorosilicone raw rubber

A technology of fluorosilicone raw rubber and high molecular weight, which is applied in the field of preparation of high molecular weight fluorosilicone raw rubber, which can solve the problems of low vinyl content, wide molecular weight distribution, and high viscosity of the system, and achieve uniform vinyl distribution and reduced volatile matter , the effect of high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

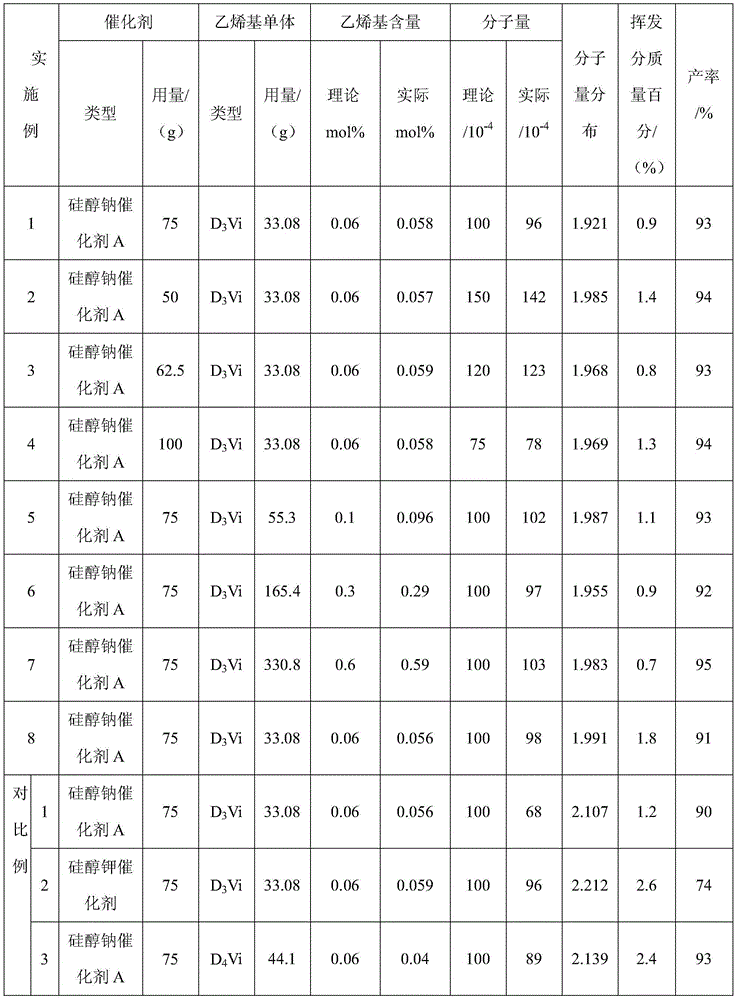

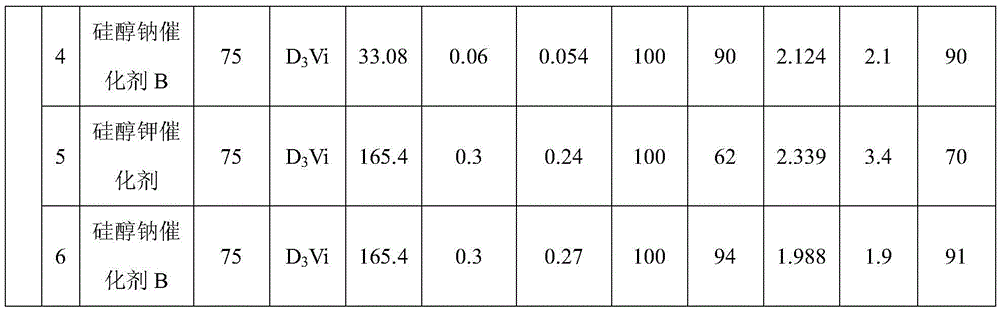

Examples

Embodiment 1

[0039] In the step (1) of Example 1, the sodium hydroxide is ground into powder, and passed through a 100-200 mesh sieve.

[0040] Example 1

[0041] A preparation method of high molecular weight fluorosilicone raw rubber, comprising steps as follows:

[0042] (1) Grind 2g of sodium hydroxide into powder, add 200g of tetramethyldivinyldisiloxane, then react at 85°C for 6h, and remove low boilers under reduced pressure to obtain a sodium silanolate catalyst, which is denoted as Sodium silanolate catalyst A;

[0043] The conditions for removing low boilers under reduced pressure are: vacuum degree -0.0096MPa, 70°C, time 2h;

[0044] (2) Put 100kgD 3 F, 33.08gD 3 Add Vi into a 200L reactor, dehydrate for 1 hour at 50°C and a vacuum of -0.0096MPa, then replace the air with high-purity nitrogen, raise the temperature to 90°C, continue to pass nitrogen, and then add 75g of sodium silanolate catalyst A, The reaction was carried out under a nitrogen atmosphere, and then the tempe...

Embodiment 2

[0051] A preparation method of high molecular weight fluorosilicone raw rubber, the preparation steps are the same as Example 1, the difference is that the amount of sodium silanolate catalyst A added in step (2) is 50g.

Embodiment 3

[0053] A preparation method of high molecular weight fluorosilicone raw rubber, the preparation steps are the same as Example 1, the difference is that the amount of sodium silanolate catalyst A added in step (2) is 62.5g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com