Polymer based nanocomposite and preparing method thereof

A nanocomposite material and composite material technology, applied in the field of polymer nanocomposite materials and their preparation, can solve the problems of high toxicity of coupling reagents, single preparation ideas, cumbersome operation, etc., and achieve simple preparation, simple operation, and improved thermal stability performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

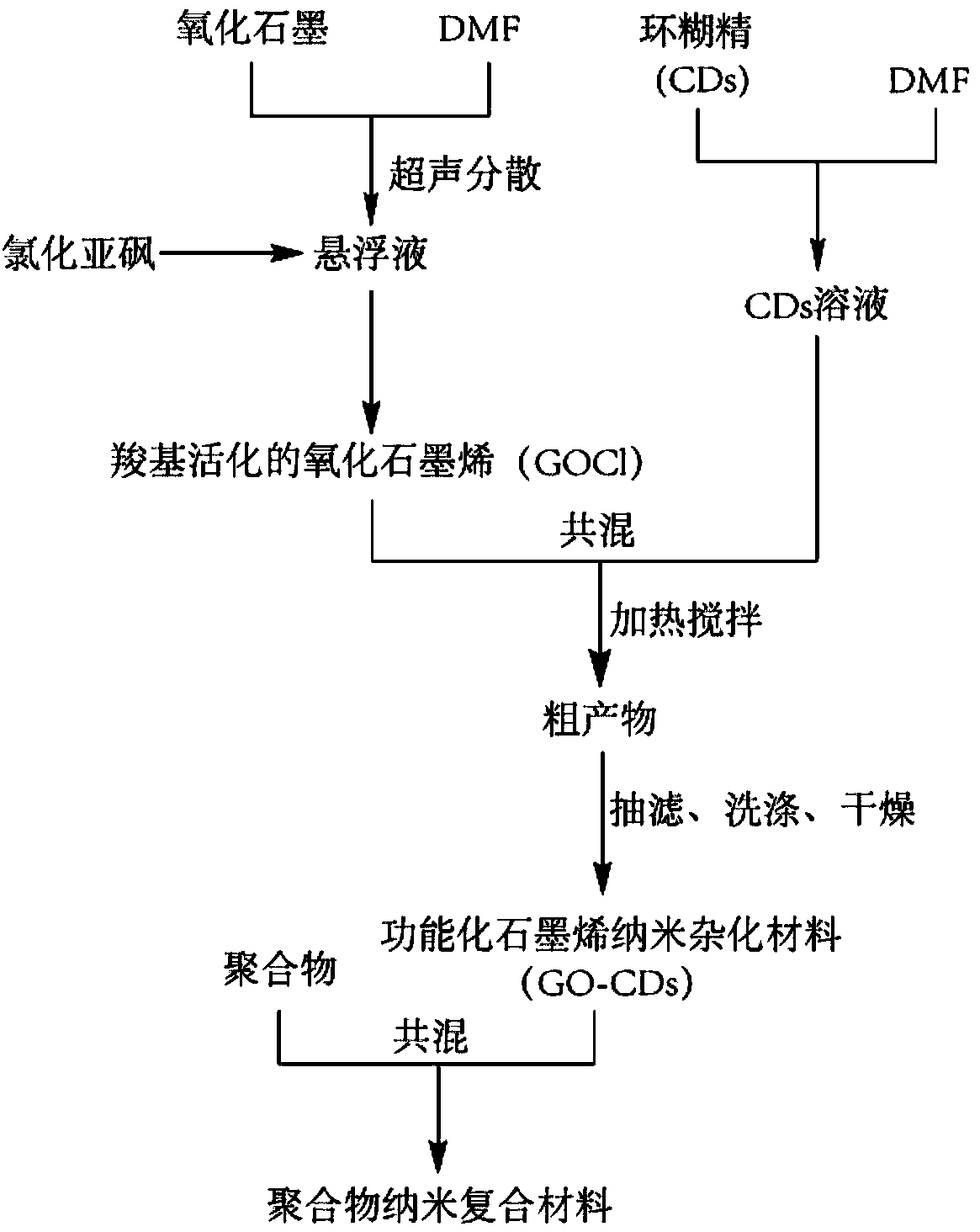

Method used

Image

Examples

Embodiment 1

[0050] The first step, the preparation of graphite oxide solid;

[0051] Pre-oxidize 20g of natural graphite (400 mesh) with 30mL of concentrated sulfuric acid, 10g of potassium persulfate and 10g of phosphorus pentoxide at 80°C, wash with water until pH = 7, and dry overnight at room temperature for use;

[0052] Cool 460mL of concentrated sulfuric acid to about 0°C, then add 20g of pre-oxidized graphite into it, slowly add 60g of potassium permanganate so that the temperature of the system does not exceed 20°C, after the addition is completed, raise the temperature to 35°C, and stir for 2 hours, And slowly add 920mL of deionized water in batches, so that the system temperature does not exceed 98°C, and after stirring for 15 minutes, add 2.8L of deionized water and 50mL of 30% hydrogen peroxide. The resulting bright yellow suspension was filtered under reduced pressure and washed. Until there is no sulfate ion in the filtrate, and when it is neutral, the product is dried in ...

Embodiment 2

[0065] The first to fourth steps are the same as steps one to four in Example 1;

[0066] In the fifth step, mix the GOCl obtained in the third step with the solution prepared in the fourth step, adjust the reaction temperature to 80°C, and react with constant temperature stirring for 2 days;

[0067] In the sixth step, the crude product obtained in the fifth step is suction-filtered, washed, and dried to obtain the β-CDs functionalized graphene nano-hybrid material, denoted as: GO-CDs 80 ;

[0068] Steps 7 to 10 are the same as steps 7 to 10 in Example 1.

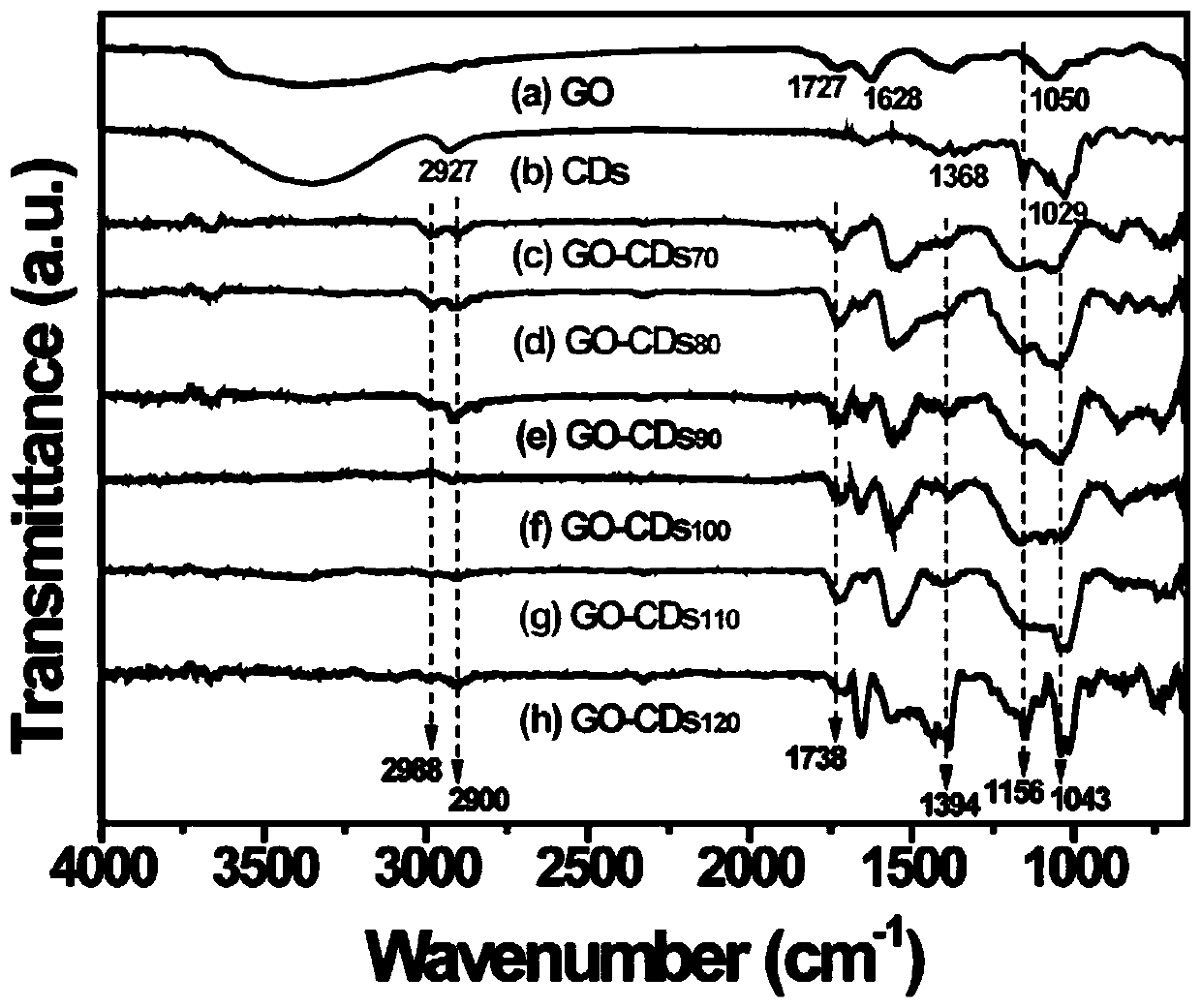

[0069] GO-CDs 80 The infrared spectrum of the filler is as image 3 d, proving that the nano-hybrid material has been successfully synthesized.

[0070] β-CDs functionalized graphene nanohybrid materials (GO-CDs 80 ) thermal stability analysis curve such as Figure 4 As shown in c, it is proved that the thermal stability of the nano-hybrid material has been greatly improved.

Embodiment 3

[0072] The first to fourth steps are the same as steps one to four in Example 1;

[0073] In the fifth step, mix the GOCl obtained in the third step with the solution prepared in the fourth step, adjust the reaction temperature to 90°C, and react with constant temperature stirring for 2 days;

[0074] In the sixth step, the crude product obtained in the fifth step is suction-filtered, washed, and dried to obtain the β-CDs functionalized graphene nano-hybrid material, denoted as: GO-CDs 90 ;

[0075] Steps 7 to 10 are the same as steps 7 to 10 in Example 1.

[0076] GO-CDs 90 The infrared spectrum of the filler is as image 3 e shows that the nano-hybrid material has been successfully synthesized.

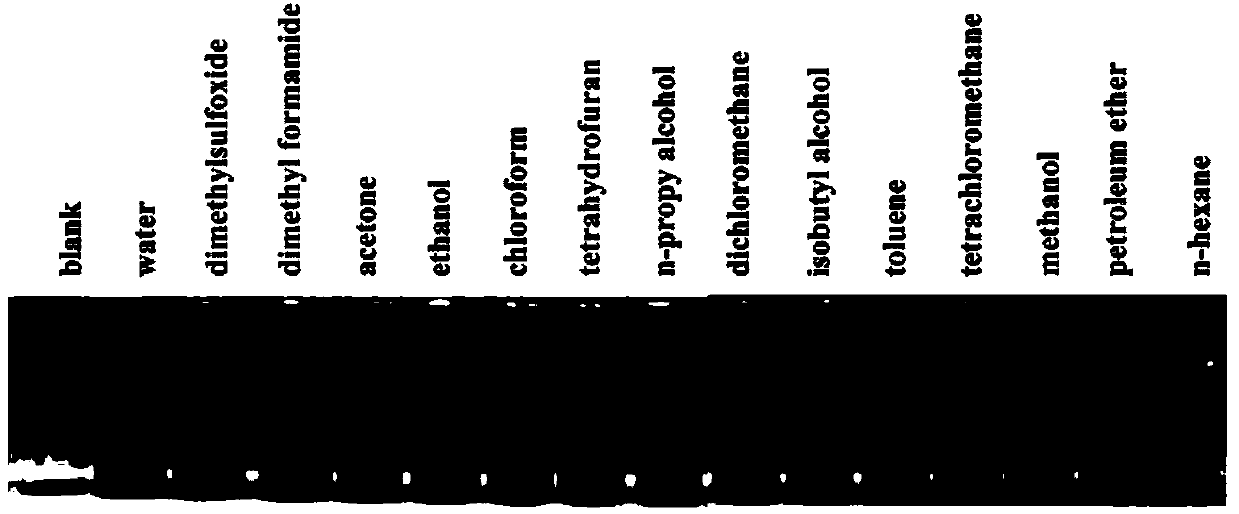

[0077] The photo of the dispersion performance of the synthesized β-CDs functionalized graphene nano-hybrid material in solvent is as follows: image 3 As shown, it can be found that it can be dispersed not only in high-polarity solvents, but even in low-polarity solvents.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com