Lithium manganate anode material and preparation method thereof

A cathode material, lithium manganate technology, used in manganate/permanganate, battery electrodes, electrical components, etc., can solve the problems of wide particle size distribution, uneven composition of synthetic materials, uneven mixing, etc. Achieve the effects of excellent high temperature cycle performance, simple preparation method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of lithium manganate cathode material, comprising the following steps:

[0024] 1) Prepare 10L of 2mol / L manganese sulfate solution, 10L of 0.1mol / L cobalt sulfate solution, and 10L of 0.05mol / L chromium sulfate solution, mix the three solutions, and stir for 1 hour to obtain a mixed salt solution;

[0025] 2) Prepare 10L each of sodium hydroxide solution and ammonia solution with a concentration of 1mol / L, and mix them to obtain a precipitant solution;

[0026] 3) Add 10L of deionized water into the 100L reaction kettle as the bottom liquid, use a peristaltic pump to control the flow rate of the mixed salt solution and the precipitant solution, and inject the two into the reaction kettle at the same time, and keep the pH of the solution in the range of 7 to 13 Inside, the temperature of the reactor is room temperature, and the stirring speed is 200 rpm, until all the salt solution is added to the reactor;

[0027] 4) According to x=1.94 in the mol...

Embodiment 2

[0032] A preparation method of lithium manganate cathode material, comprising the following steps:

[0033] 1) Prepare 10L of 0.2mol / L manganese sulfate solution, 10L of 0.02mol / L cobalt sulfate solution, and 10L of 0.02mol / L chromium nitrate solution, mix the three solutions, and stir for 1 hour to obtain a mixed salt solution;

[0034] 2) Prepare 10L each of sodium hydroxide solution and ammonia solution with a concentration of 2mol / L, and mix them to obtain a precipitant solution;

[0035] 3) Add 10L of deionized water into the 100L reaction kettle as the bottom liquid, use a peristaltic pump to control the flow rate of the mixed salt solution and the precipitant solution, and inject the two into the reaction kettle at the same time, and keep the pH of the solution in the range of 7 to 13 Inside, the temperature of the reactor is room temperature, and the stirring speed is 300 rpm, until all the salt solution is added to the reactor;

[0036] 4) According to x=1.88 in the ...

Embodiment 3

[0041] A preparation method of lithium manganate cathode material, comprising the following steps:

[0042] 1) Prepare 10L of 0.5mol / L manganese nitrate solution, 5L of 0.5mol / L cobalt nitrate solution, and 5L of 0.5mol / L chromium chloride solution, mix the three solutions, and stir for 1 hour to obtain a mixed salt solution;

[0043] 2) Prepare 10L each of sodium hydroxide solution and ammonia solution with a concentration of 3mol / L, and mix them to obtain a precipitant solution;

[0044] 3) Add 10L of deionized water into the 100L reaction kettle as the bottom liquid, use a peristaltic pump to control the flow rate of the mixed salt solution and the precipitant solution, and inject the two into the reaction kettle at the same time, and keep the pH of the solution in the range of 7 to 13 Inside, the temperature of the reaction kettle was room temperature, and the stirring speed was 300 rpm, until all the salt solution was added into the reaction kettle.

[0045]4) According ...

PUM

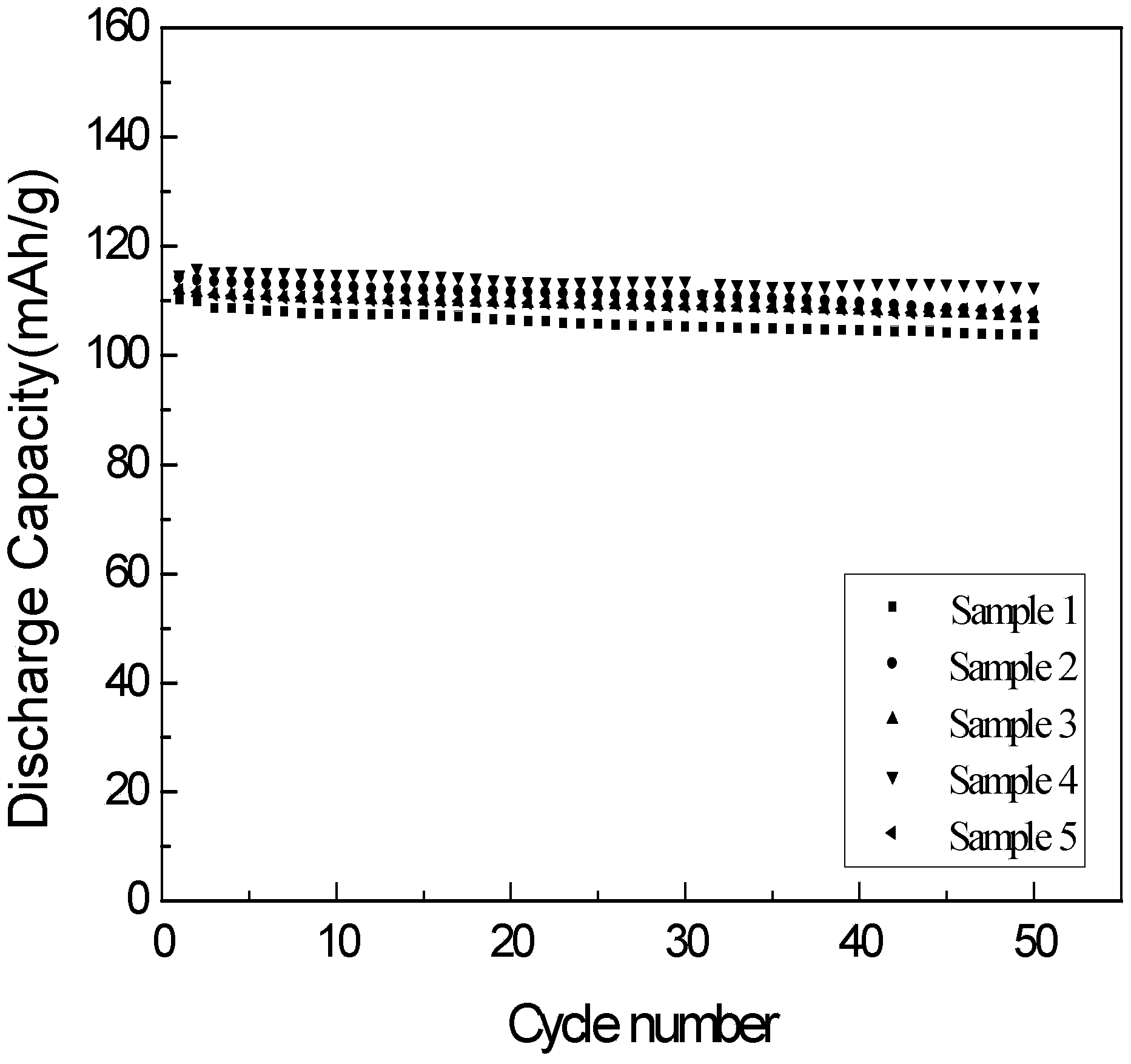

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com