Composite foam sound insulation material and preparation method thereof

A technology of sound insulation material and composite foam, which is applied in the field of composite foam sound insulation material and its preparation, can solve the problems of inconvenient installation and construction, heavy weight, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

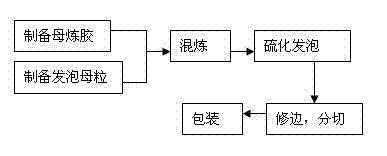

Method used

Image

Examples

Embodiment 1

[0045] Preparation of sound insulation material masterbatch:

[0046] Put 50 parts of chlorinated butyl rubber, 50 parts of hollow glass microspheres, and 20 parts of petroleum resin into a 20r / min internal mixer for mixing. The mixing temperature is 120°C, and the pressure of the top bolt is 0.4-0.8MPa. Knead for 10-15 minutes, then deglue, tamp, press, tablet, cool, park for 4-6 hours, and carry out secondary plasticating for 10-15 minutes.

[0047] Preparation of foam masterbatch:

[0048] Put 20 parts of chlorinated butyl rubber into an open mill and knead at a temperature of 80°C. After the rubber material is covered with rolls, add 20 parts of sodium bicarbonate in batches.

[0049] 20 parts of chlorinated butyl rubber, 120 parts of sound insulation material masterbatch, 12 parts of stearic acid, 1.5-2.5 parts of peptizer, 2 parts of DM, 3 parts of MgO2, 1 part of TMTD, 3 parts of ZnO, foaming agent master 40 parts of granules were put into the internal mixer, the mixi...

Embodiment 2

[0053] Preparation of sound insulation material masterbatch:

[0054] Mix 50 parts of bromobutyl rubber, 50 parts of barium sulfate, and 20 parts of petroleum resin in a 20r / min internal mixer. 10-15 minutes, then degumming, stamping, pressing, tableting, cooling, parking for 4-6 hours, and second plasticizing for 10-15 minutes.

[0055] Preparation of foam masterbatch:

[0056] Put 20 parts of bromobutyl rubber into an open mill and knead at a temperature of 80°C. After the rubber is covered with rolls, add 10 parts of BOSH foaming agent in batches.

[0057] 20 parts of bromobutyl rubber, 120 parts of sound insulation material masterbatch, 12 parts of stearic acid, 1.5-2.5 parts of peptizer, 2 parts of DM, 3 parts of MgO2, 1 part of TMTD, 3 parts of ZnO, foaming agent master 40 parts of granules were put into the internal mixer, the mixing temperature was 80°C, and the mixing was done for 10 minutes; glue removal, pounding, tableting, and tableting.

[0058] Put it into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com