High-sound-insulation gypsum plaster board and preparation method thereof

A paper-faced gypsum board and high-separation technology, which is applied in construction, building structure, covering/lining, etc., can solve the problems of poor lap density of gypsum crystals, many open pores of gypsum boards, and reduced surface density of gypsum boards. Achieve the effect of improving workability and fluidity, increasing sound insulation performance, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

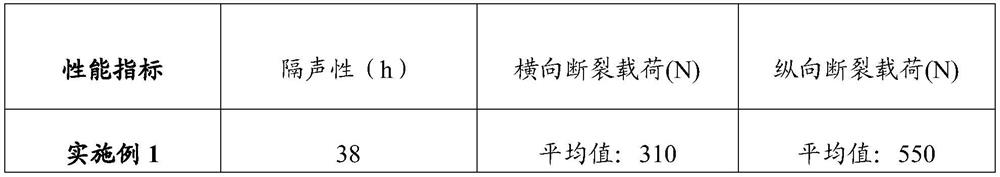

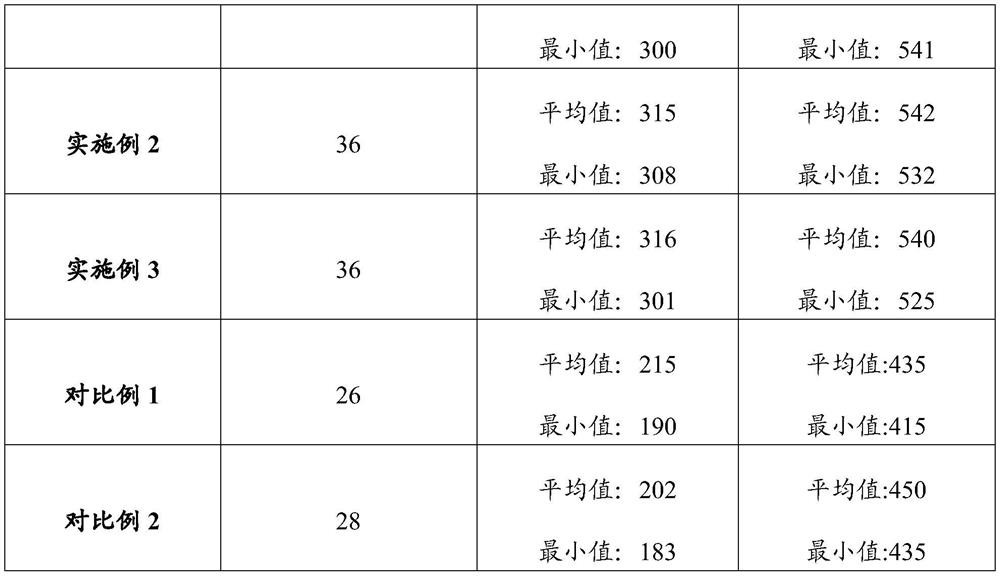

Examples

Embodiment 1

[0041] In the gypsum board prepared in this example, the specific surface area of the gypsum clinker is 3200 cm 2 / g; the first component in the sound insulation material is alkali-free glass fiber, and the second component is polypropylene butyl rubber blended fiber produced by Jinrun Rubber; the mass ratio of the first component and the second component is 2:1; the length of the glass fiber is 10 mm, and the single filament diameter of the glass fiber is 5 μm. The foaming agent is formulated from sodium lauryl sulfate produced by Futeng Chemical Industry and silicone resin polyether emulsion produced by Damai Chemical Industry; the mass ratio of the two is 1:1. The modified starch is modified cornstarch, and the rubber powder is the 5010N rubber powder produced by Wacker Chemical; the water reducer is the 312 water reducer produced by BASF;

[0042] The paper surface gypsum board that the present embodiment makes, concrete preparation steps are as follows:

[0043] 1) We...

Embodiment 2

[0048] In the gypsum board prepared in this embodiment, the specific surface area of the gypsum clinker is 3800 cm 2 / g; the first component in the sound insulation material is alkali-resistant glass fiber, and the second component is polypropylene butyl rubber produced by Jinrun Rubber; the mass ratio of the first component to the second component is 3:1 ; The length of the glass fiber is 15 mm, and the single filament diameter of the glass fiber is 10 μm. The foaming agent is formulated from sodium dodecylbenzenesulfonate produced by Futeng Chemical Industry and silicone resin polyether emulsion produced by Damai Chemical Industry; the mass ratio of the two is 1:1. The modified starch is modified tapioca starch, and the rubber powder is the 5044N rubber powder produced by Wacker Chemical; the water reducer is the F10 type melamine water reducer produced by BASF;

[0049] The paper surface gypsum board that the present embodiment makes, concrete preparation steps are as fo...

Embodiment 3

[0055] In the gypsum board prepared in this example, the specific surface area of the gypsum clinker is 4200 cm 2 / g; the first component in the sound insulation material is alkali-resistant glass fiber, and the second component is polypropylene butyl rubber produced by Jinrun Rubber; the mass ratio of the first component to the second component is 4:1 ; The length of the glass fiber is 20 mm, and the single filament diameter of the glass fiber is 18 μm. The foaming agent is formulated from sodium lauryl sulfate produced by Futeng Chemical and silicone resin polyether emulsion produced by Damai Chemical; the mass ratio of the two is 1:1. The modified starch is modified corn starch, and the rubber powder is 5544N rubber powder produced by Wacker Chemical; the water reducer is the KS-05 naphthalene water reducer produced by Sika;

[0056] The paper surface gypsum board that the present embodiment makes, concrete preparation steps are as follows:

[0057] 1) Weigh 100 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com