Method for preparing large-diameter seamless tubular product by squeezing equipment

A technology of seamless pipes and extrusion equipment, applied in the field of steel pipe processing, can solve the problems of difficulty in mass production of composite pipes, complex process flow, adverse effects on pipe fatigue strength and service life, etc., and achieves easy control of pipe wall thickness, Guarantee the quality of products and the effect of dense organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

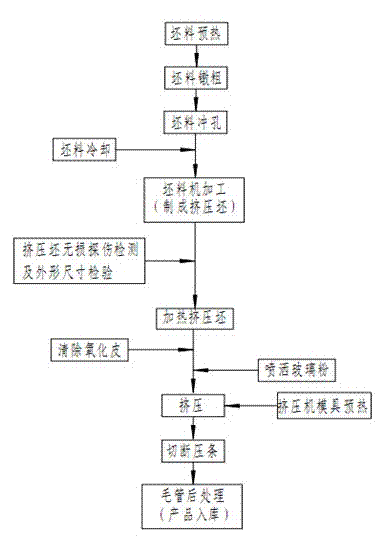

[0037] Referring to Figure 1, taking ASME TP304L austenitic stainless steel large-diameter seamless steel pipe as an example to illustrate the hot extrusion process manufacturing method of using extrusion equipment to manufacture large-diameter special alloy pipes, the product size parameters of the steel pipe are: outer diameter φ406.4 ~φ1320.8mm, wall thickness 20~240mm, steel pipe length ≤13 meters. Its specific operation steps are:

[0038] ⅰ. Billet preheating: Electroslag steel ingot is used as the billet, and its quality and size are combined with extrusion process technical conditions. It is heated in a natural gas chamber furnace and heated in three steps. The maximum furnace temperature is 1220°C.

[0039] ⅱ. Billet upsetting: the billet is made on a 160MN three-station billet making machine, and the hollow billet is made through free upsetting, closed upsetting, punching and piercing operations.

[0040] Ⅲ. The extruded billet is cooled to room temperature in an un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com