Preparation method for mesoporous carbon-based solid acid catalyst and application of mesoporous carbon-based solid acid catalyst

A solid acid catalyst and mesoporous carbon technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, fatty acid esterification, etc., can solve problems such as difficult product purification, improper waste liquid treatment, and difficulty in continuous production. High catalytic esterification and acid reduction activity, suitable strength and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1. Weigh 1.6g of glucose, 0.16g of concentrated sulfuric acid and 30mL of distilled water, mix and stir to obtain a clear solution, and use supercritical carbon dioxide as a solvent to introduce it into 1g of mesoporous silica SBA-15 casting powder , wherein the mass fraction of carbon dioxide in the mixed solution is 80%, which is maintained for 2 hours. Then the mixture was dried at 100° C. for 6 hours, and then heated to 160° C. for pre-carbonization for 6 hours to obtain a carbon-silicon composite. Then put it in a tube furnace, raise the temperature to 900°C at 1°C / min under a nitrogen atmosphere, and roast for 5 hours, mix the obtained solid with 5g 2mol / L sodium hydroxide solution, and stir at room temperature for 24 hours to remove SiO, after filtering and washing, vacuum drying at 100° C. for 6 hours to obtain the mesoporous carbon material. Take 1 g of mesoporous carbon material and 20 mL of concentrated sulfuric acid, put them into a polytetrafluoroe...

Embodiment 2

[0035] Embodiment 2. Weigh 1.0g sucrose, 0.18g phosphoric acid and 30mL distilled water, mix and stir to obtain a clear solution, and use supercritical carbon dioxide as a solvent to import it into 1g of mesoporous silica MCM-48 casting powder, Wherein the mass fraction of carbon dioxide accounting for the mixture is 60%, which is maintained for 4 hours. Then the mixture was dried at 100° C. for 6 hours, and then heated to 160° C. for pre-carbonization for 6 hours to obtain a carbon-silicon composite. Then put it in a tube furnace, raise the temperature to 800°C at 5°C / min under a nitrogen atmosphere, and carbonize it for 8 hours. SiO, after filtering and washing, vacuum drying at 100° C. for 6 hours to obtain the mesoporous carbon material. Take 1 g of mesoporous carbon material and 20 mL of p-toluenesulfonic acid, put them into a polytetrafluoroethylene-lined reactor, keep at 180 °C for 10 hours, and cool to room temperature naturally. After filtering, washing with distill...

Embodiment 3

[0036] Embodiment 3. Take by weighing 2.0g glycerin, 0.12g hydrochloric acid and 30mL distilled water, mix and stir to obtain clear solution, and with supercritical carbon dioxide as solvent, it is imported in 1g mesoporous silica KIT-6 mold powder, Wherein the mass fraction of carbon dioxide accounting for the mixed liquid is 40%, which is maintained for 8 hours. Then the mixture was dried at 100° C. for 6 hours, and then heated to 160° C. for pre-carbonization for 6 hours to obtain a carbon-silicon composite. Then put it in a tube furnace, heat up to 700°C at 10°C / min under a nitrogen atmosphere, and carbonize it for 10 hours. The resulting solid is mixed with 20mL of hydrofluoric acid solution and stirred at room temperature for 24 hours to remove the mesoporous silica. , after filtering and washing, vacuum drying at 100° C. for 6 hours to obtain the mesoporous carbon material. Take 1 g of mesoporous carbon material and 20 mL of phosphoric acid, put them into a polytetrafl...

PUM

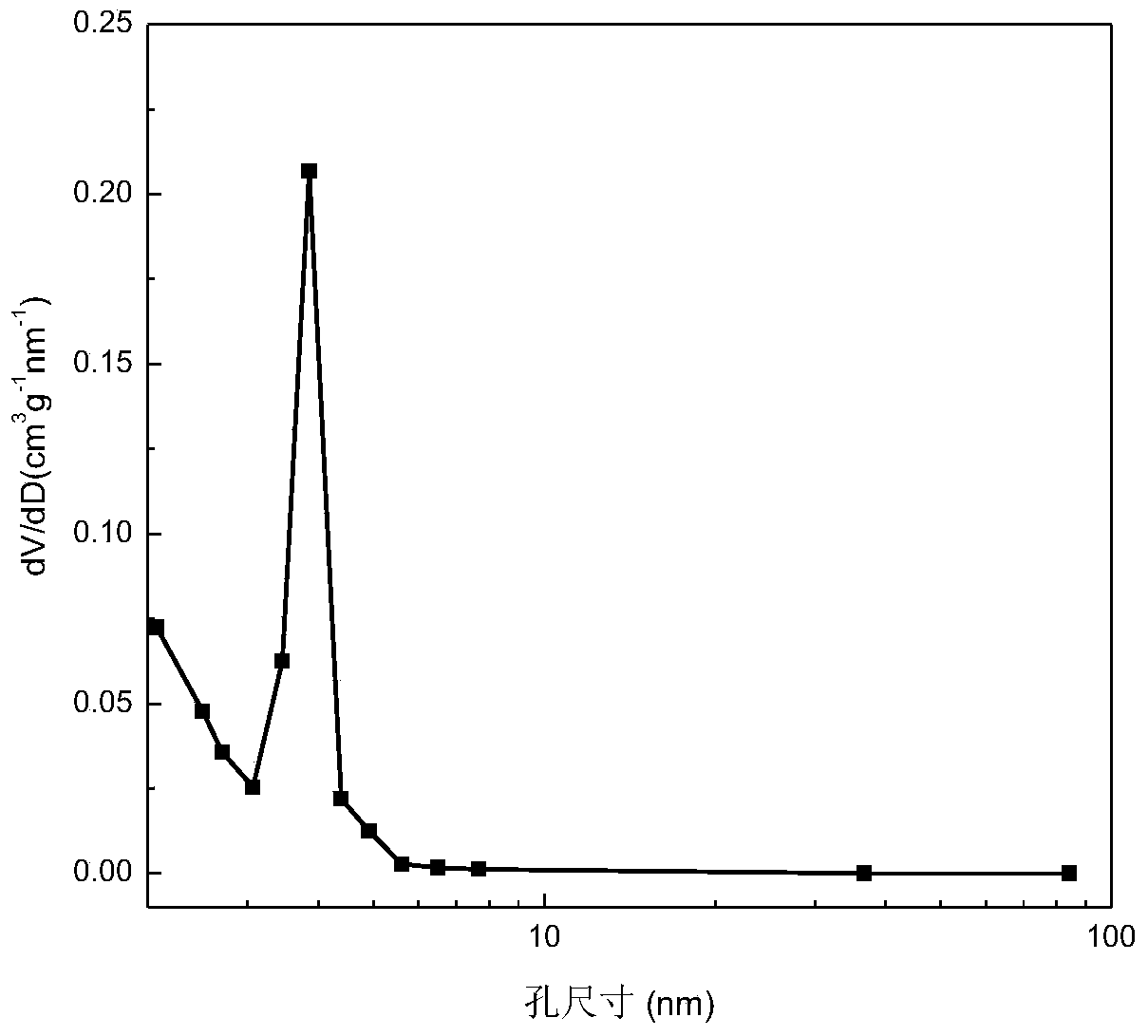

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com