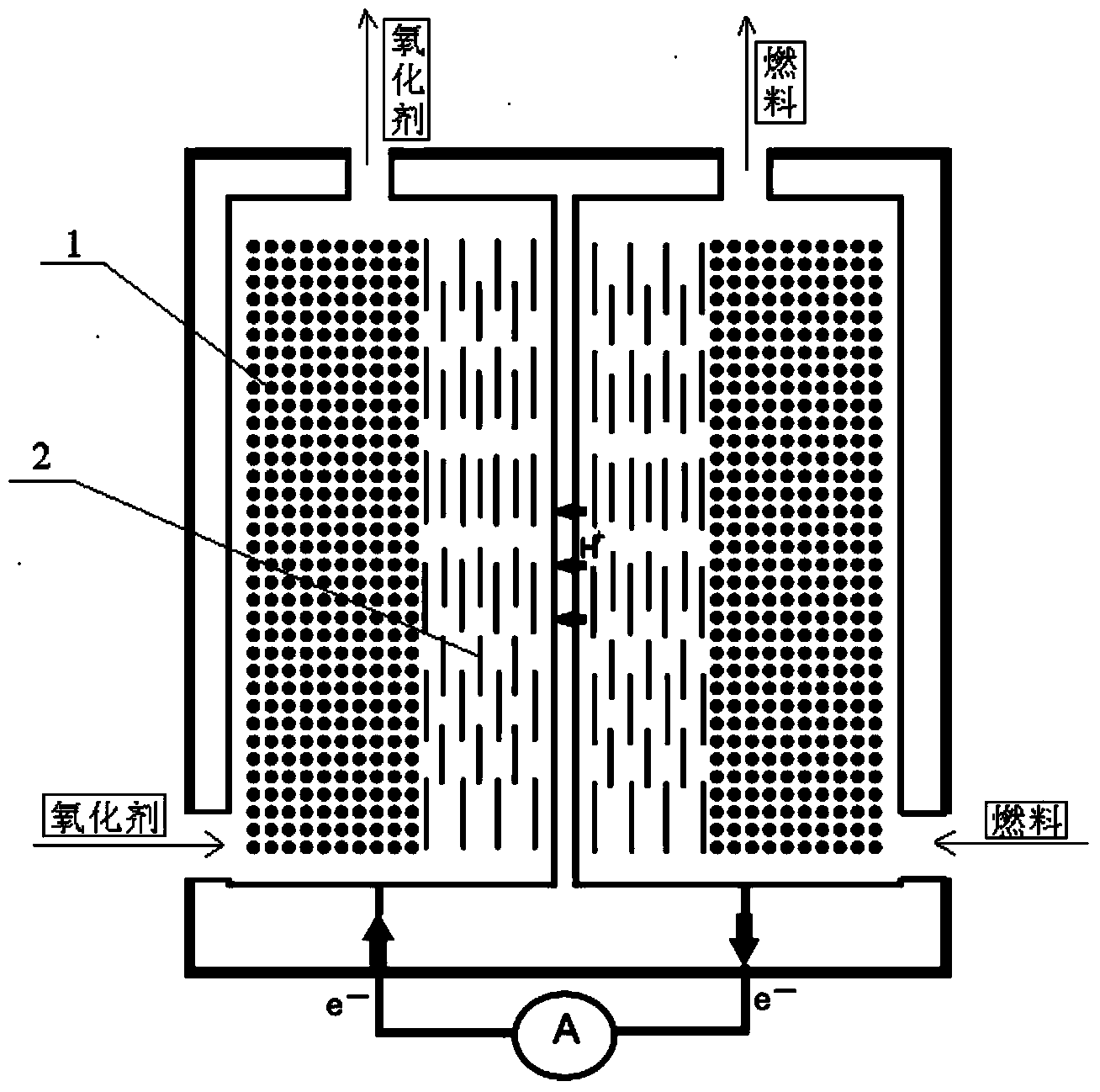

Micro membrane-free fuel cell with carbon-nanotube three-dimensional electrodes and preparation method thereof

A technology of carbon nanotubes and three-dimensional electrodes, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low power density and low fuel utilization rate, and achieve the effect of increasing contact area, high power density and fuel utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

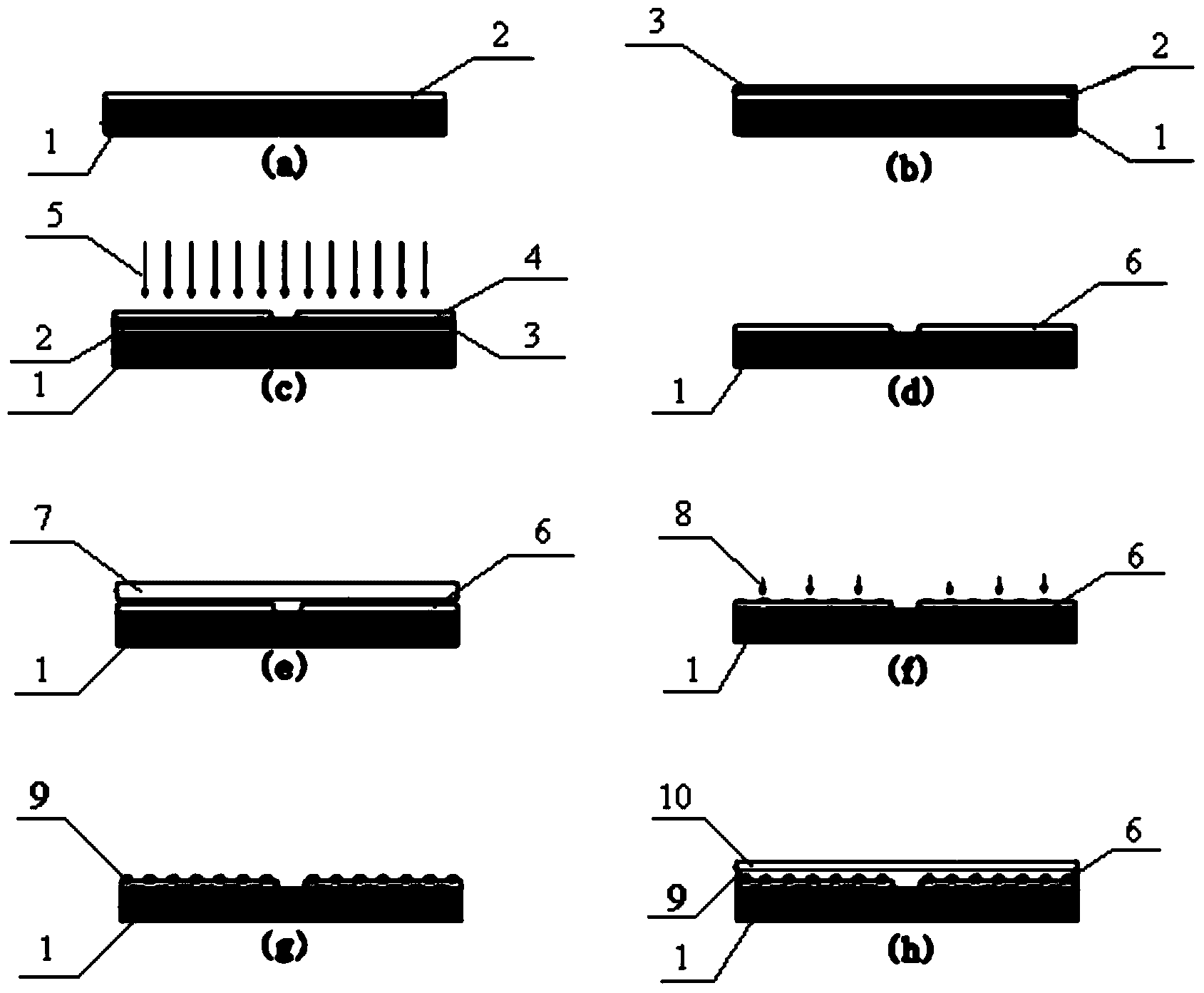

[0029] A micro-filmless fuel cell containing a carbon nanotube three-dimensional electrode is prepared by the following method, specifically comprising the following steps:

[0030] (1) Prepare metal electrode leads on the substrate:

[0031] 1.1 Prepare a layer of chromium metal film on the cleaned glass sheet (substrate) by magnetron sputtering method. The chromium metal film is used as the transition layer of the metal electrode lead. The process parameters of the magnetron sputtering method are: cavity Pressure 0.6Pa, sputtering power 100W, argon flow rate 12cm 2 / min, sputtering time 2min; adopt DC sputtering method to prepare a layer of gold metal film on the chromium metal film, the gold metal film is used as the conductive layer of the metal electrode lead, the process parameters of DC sputtering are: cavity pressure 8Pa , working current 8mA, sputtering time 90s; complete the preparation of chromium-gold double-layer metal film;

Embodiment 2

[0043] A micro-filmless fuel cell containing a carbon nanotube three-dimensional electrode is prepared by the following method, specifically comprising the following steps:

[0044] (1) Prepare metal electrode leads on the substrate:

[0045] 1.1 Prepare a layer of chromium metal film on the cleaned silicon wafer (substrate) by magnetron sputtering method. The process parameters of magnetron sputtering method are: chamber pressure 0.5Pa, sputtering power 80W, argon flow rate 10cm 2 / min, sputtering time 3min; adopt DC secondary sputtering method to prepare a layer of gold metal film on the chromium metal film, this gold metal film is used as the conductive layer of metal electrode lead wire, the process parameter of DC secondary sputtering is: The cavity pressure is 9Pa, the working current is 10mA, and the sputtering time is 80s; the preparation of the chromium-gold double-layer metal film is completed;

[0046] 1.2 Use a coating machine to coat a layer of photoresist on the...

Embodiment 3

[0057] A micro-filmless fuel cell containing a carbon nanotube three-dimensional electrode is prepared by the following method, specifically comprising the following steps:

[0058] (1) Preparing metal electrode leads on the substrate: the same method as in Example 2 for preparing metal electrode leads.

[0059] (2) Printing catalyst paste for catalyzing carbon nanotube growth on Cr / Au metal leads:

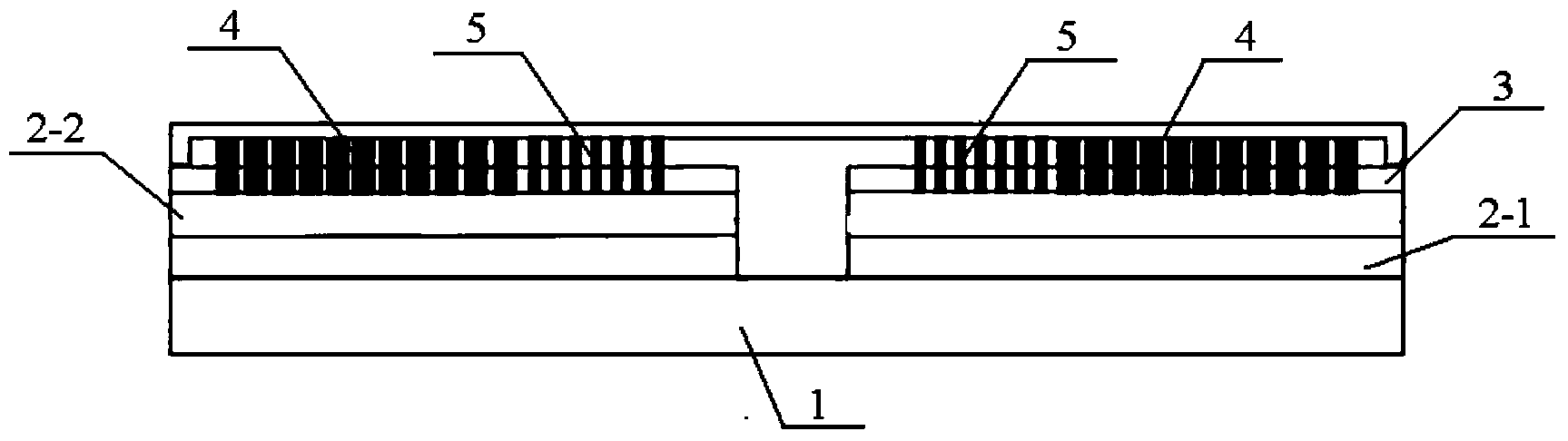

[0060] 1.1 According to the position requirements of the carbon nanotube stereoscopic electrode and the guide screen (see figure 2 ), use PDMS (polydimethylsiloxane) as material to prepare PDMS stamp;

[0061] 1.2 A catalyst slurry composed of iron metal salt and polyethylene glycol was printed on the Cr / Au metal wire by using a PDMS transfer stamp, and the role of the catalyst slurry was to catalyze the growth of carbon nanotubes.

[0062] (3) On the above-mentioned Cr / Au metal leads printed with catalyst paste, carbon nanotube stereoscopic electrodes and guide mesh plates wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rate density | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com