Composite negative plate for lithium ion battery as well as preparation method of composite negative plate and lithium ion battery

A technology for lithium-ion batteries and negative plates, applied in electrode manufacturing, battery electrodes, electrode rolling/calendering, etc., can solve problems such as battery deformation, battery short circuit, etc., achieve long service life, improve cycle service life, and be easy to prepare Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

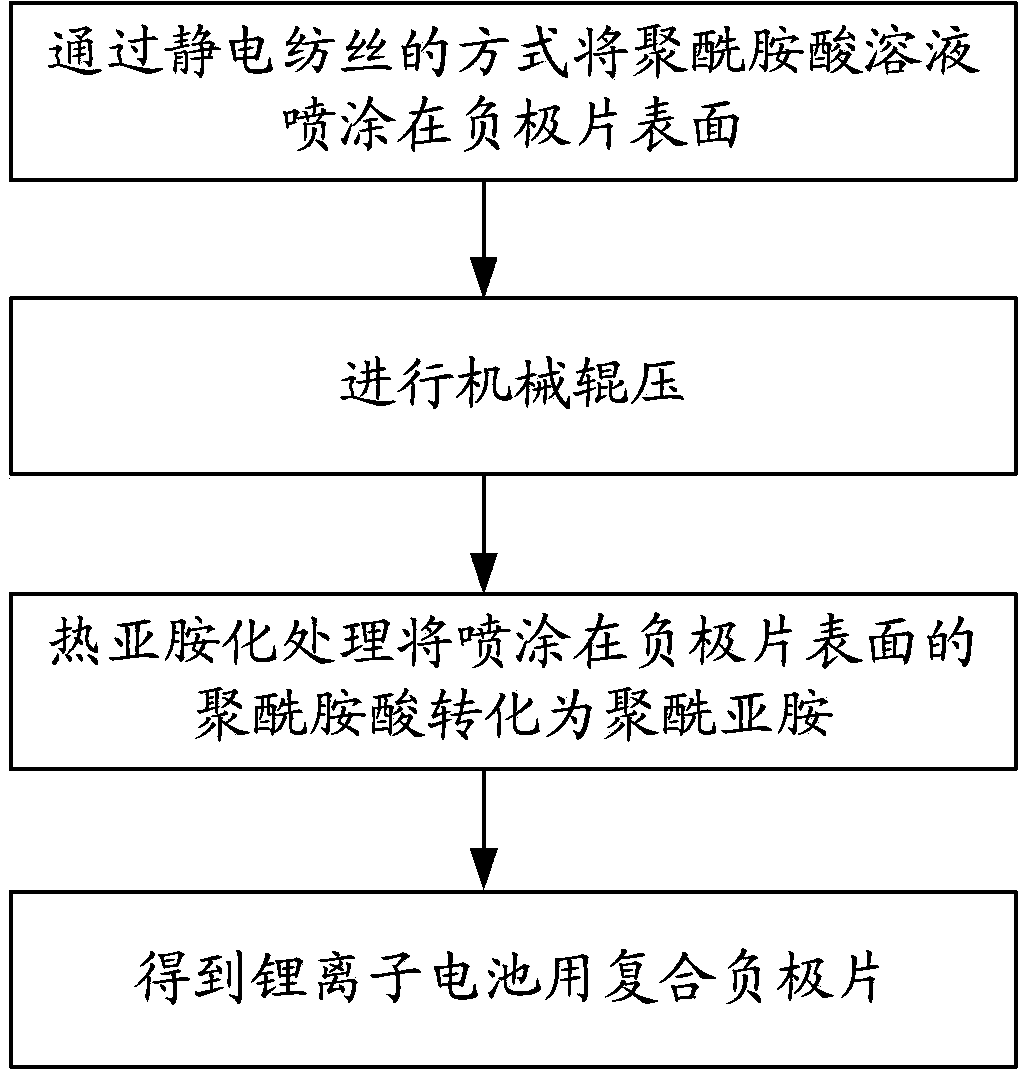

[0048] In a second aspect, embodiments of the present invention provide a method for preparing a composite negative electrode sheet for a lithium-ion battery, such as figure 1 As shown, it includes the following steps: spray the polyamic acid solution on the surface of the negative electrode sheet by electrospinning, then carry out mechanical rolling, and finally convert the polyamic acid sprayed on the surface of the negative electrode sheet into polyamide by thermal imidization treatment. imine, and form a polyimide nanofiber film on the surface of the negative electrode sheet to obtain a composite negative electrode sheet for lithium ion batteries.

[0049] In the second aspect of the embodiment of the present invention, the polyamic acid solution is prepared as follows: add a binary organic acid anhydride and an organic diamine into an organic solvent, stir, and undergo condensation reaction to obtain a polyamic acid solution.

[0050] The binary organic acid anhydrides ar...

Embodiment 1

[0077] A preparation method for a composite negative electrode sheet for a lithium ion battery, comprising the steps of:

[0078] (1) Synthesis of polyamic acid solution

[0079] Add 45 grams of pyromellitic dianhydride (PMDA) and 42 grams of diaminodiphenyl ether (ODA) to the mixing tank, add 500 milliliters of N, N-dimethylformamide (DMF), and then The mixture was stirred and reacted for 2 hours, and a condensation reaction occurred to obtain a uniform polyamic acid solution.

[0080] (2) Negative sheet preparation

[0081] The mixture of 200 grams of negative electrode active material artificial graphite, 3 grams of binder styrene-butadiene rubber (SBR) and 3 grams of carboxymethyl cellulose (CMC) is added to 200 grams of water, then stirred in a vacuum mixer to form a uniform slurry . The slurry was evenly coated on both sides of a 9-micron copper foil, and the surface density of the coating was controlled to be 17.8 mg / cm2, then dried at 100° C., and rolled to obtain a...

Embodiment 2

[0090] A preparation method for a composite negative electrode sheet for a lithium ion battery, comprising the steps of:

[0091] (1) Synthesis of polyamic acid solution

[0092] Add 45 grams of isopropyl diphthalic anhydride and 42 grams of diphenylsulfone diamine into the mixing tank, add 500 milliliters of N, N-dimethylacetamide (DMAc), then stir and react at 10°C for 8 hours, and condensation occurs The reaction obtains a uniform polyamic acid solution.

[0093] (2) Negative sheet preparation

[0094] The mixture of 200 grams of negative electrode active material artificial graphite, 3 grams of binder styrene-butadiene rubber (SBR) and 3 grams of carboxymethyl cellulose (CMC) is added to 200 grams of water, then stirred in a vacuum mixer to form a uniform slurry . The slurry was evenly coated on both sides of a 9-micron copper foil, and the surface density of the coating was controlled to be 17.8 mg / cm2, then dried at 100° C., and rolled to obtain a negative electrode s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Needle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com