Carbon powder canister material level meter

A powdered carbon and tank material technology, applied in the field of material level gauges, can solve problems such as carbon black environmental pollution, flammable gas explosion, and measurement inconvenience, and achieve the effects of accurate measurement signals, overcoming short circuits, and simple results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

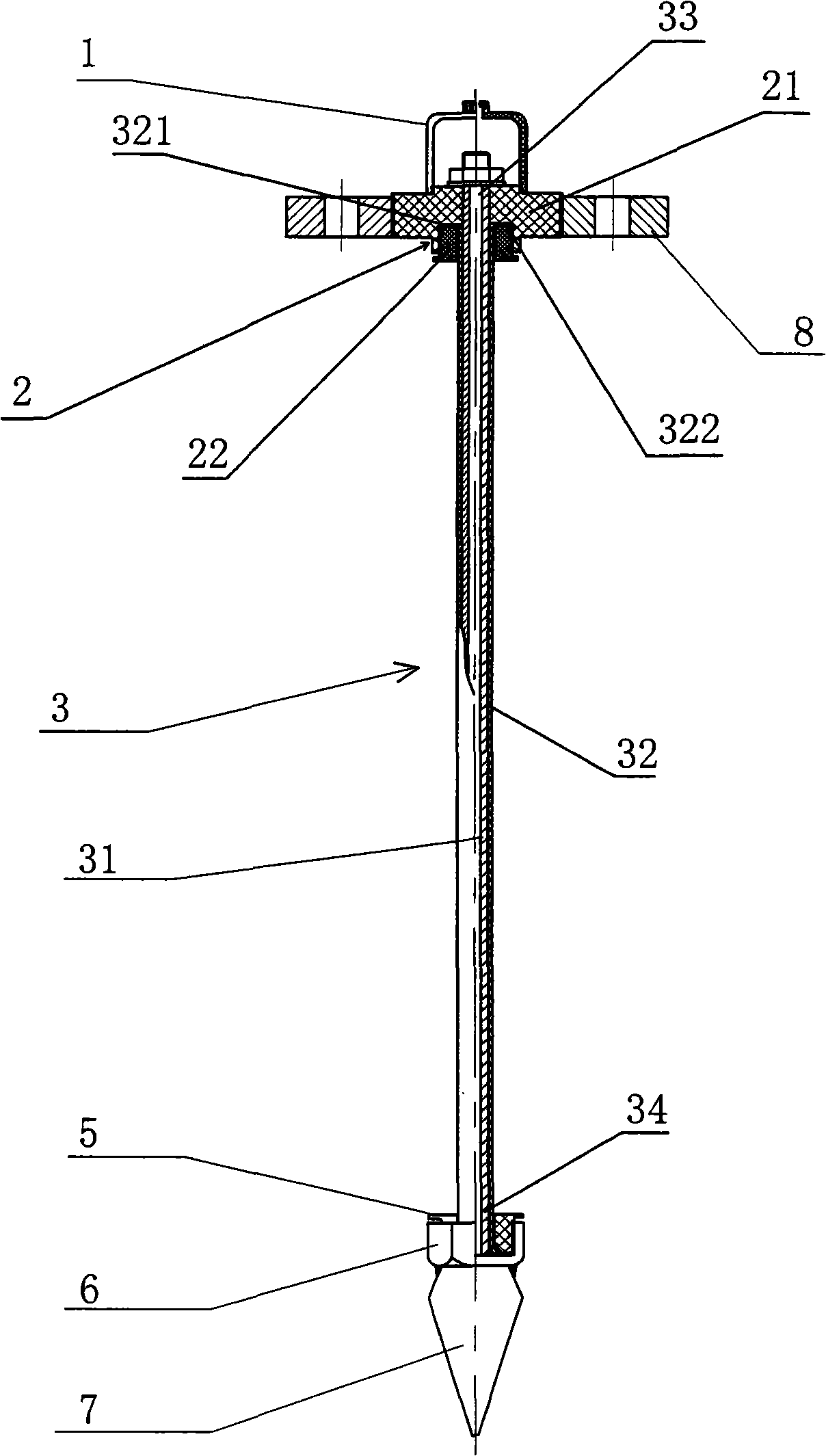

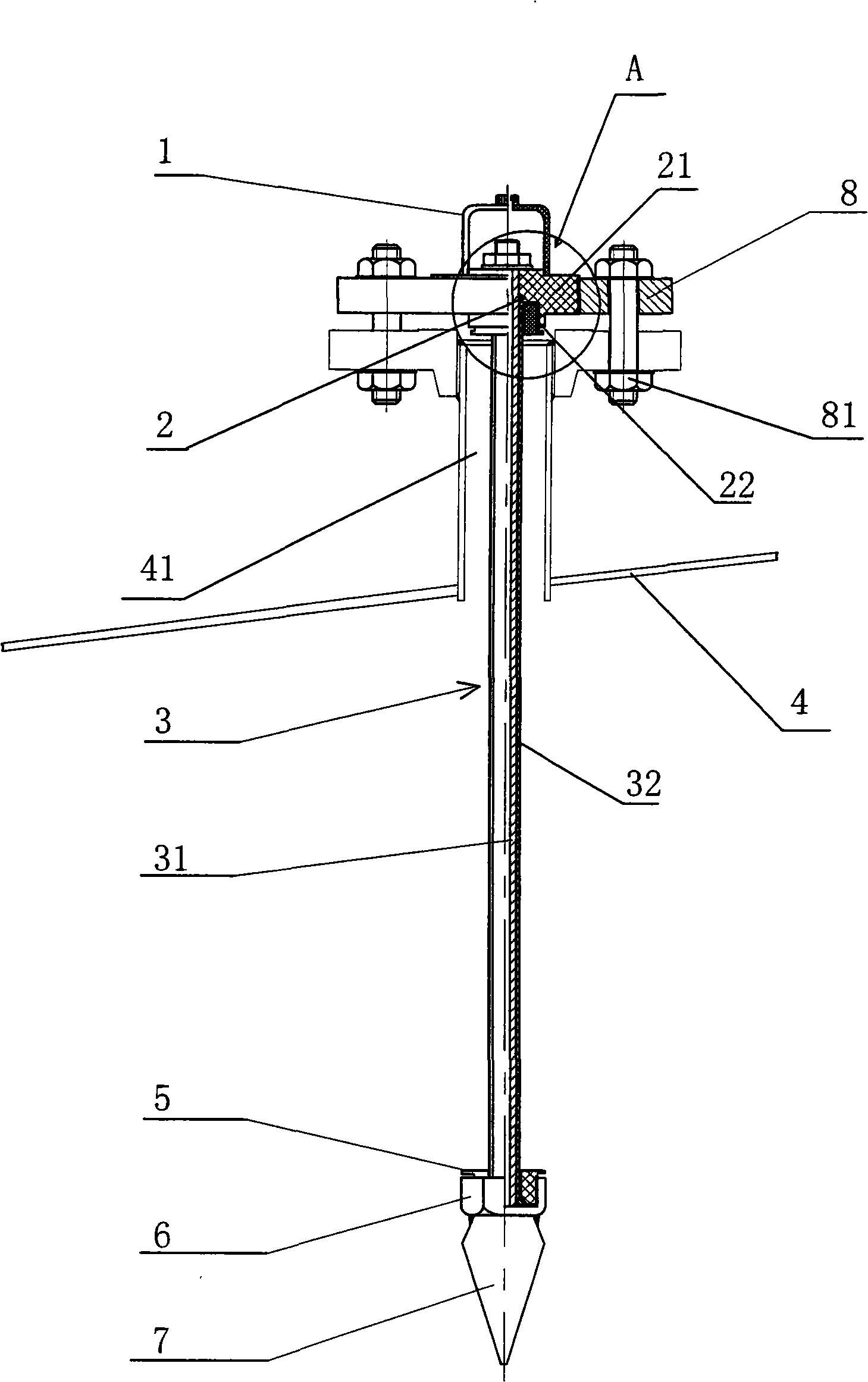

[0018] see Figure 2 ~ Figure 4 , the powder charcoal tank material level meter disclosed by the present invention is installed on the powder charcoal tank 4, and is used to detect the position height and the level change of the carbon black distribution in the powder charcoal tank 4, including a junction box 1, connected to the junction box 1 Tube 3 , first lock 2 and second lock 5 , flange 8 , and a probe 7 . The connecting pipe 3 extends inside the powder-coke tank 4 and includes a conductive wire tube 31 and an insulating wire tube 32 wrapped around the conductive wire tube 31 .

[0019] The conductive wire tube 31 is a hollow armored wire-disturbing tube. In this embodiment, it is a very thin flexible hollow tube processed from a stainless steel. The tube material not only has a certain degree of flexibility, but also has a considerable Strength of. It is bendable during transportation and installation, so it can be made into any length probe. In other embodiments of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com