Preparation method for low-density porous metal material

A porous metal and low-density technology, which is applied in the field of preparation of low-density porous metal materials, can solve the problems of high cost, complicated preparation process, and large pore size, and achieve the effects of high porosity, high specific surface area, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

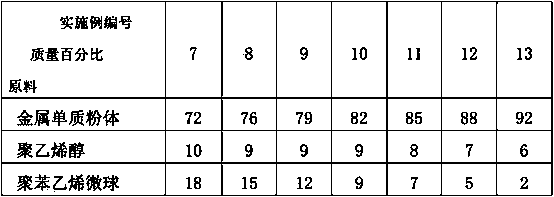

Examples

Embodiment 1

[0028] A method for preparing a low-density porous metal material (low-density porous iron), comprising the following steps:

[0029] (1) Use 0.2-0.5μm iron powder as the original metal powder, 10μm industrial grade PS microspheres as the pore-forming agent, completely dissolve 0.5g PVA in 10ml deionized water by magnetic stirring, take 0.5g PS microspheres and add the above In the PVA aqueous solution, the PS balls were uniformly dispersed by ultrasonic stirring, and then 4.0 g of iron powder was added, ultrasonically dispersed and stirred to form a uniformly dispersed slurry.

[0030] (2) Insert a cylindrical polytetrafluoroethylene tube into the slurry, and the inner diameter of the mold tube is 5.0mm, then place the sample container in the freezing cavity, and use liquid nitrogen as the freezing medium for freezing and molding. After freezing, the container was removed and placed in a vacuum drying oven for dehydration and drying, and the dried sample was demolded.

[003...

Embodiment 2

[0033] A method for preparing a low-density porous metal material (low-density porous aluminum), comprising the following steps:

[0034] (1) Use 0.5-1.0μm aluminum powder as the original metal powder, 10μm industrial grade PS microspheres as the pore-forming agent, completely dissolve 0.5g PVA in 10ml deionized water by magnetic stirring, take 0.8g PS microspheres and add the above In the PVA aqueous solution, the PS balls were uniformly dispersed by ultrasonic stirring, and then 3.7 g of aluminum powder was added, ultrasonically dispersed and stirred to form a uniformly dispersed slurry.

[0035] (2) Insert a cylindrical polytetrafluoroethylene tube into the slurry, and the inner diameter of the mold tube is 10 mm, then place the sample container in the freezing cavity, and use heavy oil as the freezing medium for freezing and molding. After freezing, the container was removed and placed in a vacuum drying oven for dehydration and drying, and the dried sample was demolded. ...

Embodiment 3

[0038] A method for preparing a low-density porous metal material (low-density porous copper), comprising the following steps:

[0039] (1) With 1.0-5.5μm copper powder as the original metal powder and 20μm industrial-grade PS microspheres as the pore-forming agent, completely dissolve 0.5g of PVA in 10ml of deionized water by magnetic stirring, take 1.0g of PS microspheres and add them to the above In the PVA aqueous solution, the PS balls were uniformly dispersed by ultrasonic stirring, and then 3.5 g of copper powder was added, ultrasonically dispersed and stirred to form a uniformly dispersed slurry.

[0040](2) Insert a cylindrical polytetrafluoroethylene tube into the slurry, and the inner diameter of the mold tube is 10mm, then place the sample container in the freezing cavity, and use liquid nitrogen as the freezing medium for freezing and molding. After freezing, the container was removed and placed in a vacuum drying oven for dehydration and drying, and the dried sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com