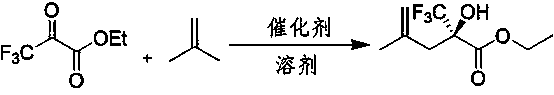

Method for preparing (R)-2-hydroxyl-2-trifluoromethyl-4-methyl-4-ethyl pentenoate under asymmetric catalysis at low temperature

A technology for ethyl pentenoate and catalytic preparation, applied in asymmetric synthesis, organic chemistry methods, chemical instruments and methods, etc., can solve problems such as high price of asymmetric catalysts, and achieve high yield and good stereoselectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

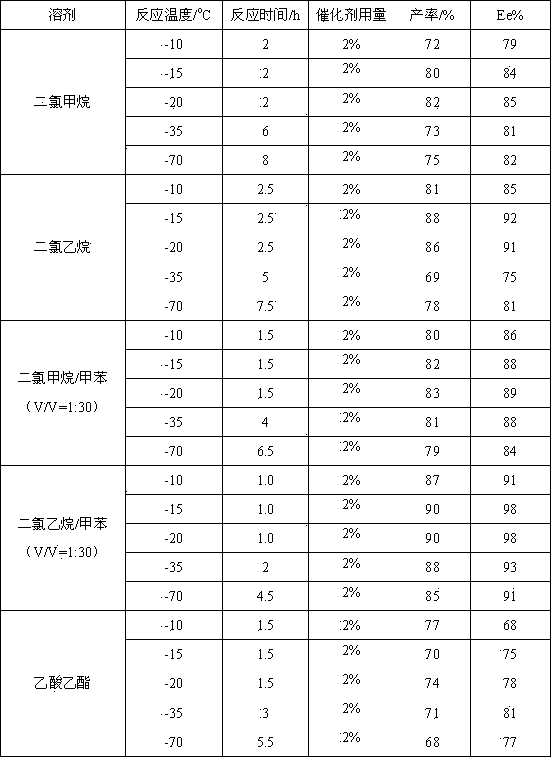

[0034] Example 1: Preparation of pure (R)-2-hydroxy-2-trifluoromethyl-4-methyl-4-pentenoic acid ethyl ester with a yield of 90% and an ee value of 98%.

[0035] Preferably (Pd / Sunphos, Ligand L1, Ar=phenyl) take ethyl trifluoropyruvate (8.505 g, 50 mmol, 1 eq) and place it in a baked reaction tube, and prepare the prepared catalyst as catalyst Solution, measured with a syringe (0.80 mL, concentration 8 g / L, 5 μmol, 0.01% eq) and added to the reaction system, stirred at room temperature for 30 minutes, then cooled the reaction system to -15 ~-20 o C. Add the prepared isobutene solution (364 g / L, solvent is toluene) into the reaction system to start the reaction. After the reaction was finished, post-treatment and distillation were carried out to obtain a colorless oily pure product. The resulting pure product has an enantiomeric excess of 98%: Rf = 0.59 (ethyl acetate : petroleum ether = 1 / 50), boiling point 97-103°C (60 mmHg); [α] D 23.7 = -6.8 o (c = 2.47, CHCl 3 ); H-N...

Embodiment 2

[0036] Example 2: Preparation of pure (R)-2-hydroxy-2-trifluoromethyl-4-methyl-4-pentenoic acid ethyl ester with 88% yield and 95% ee value.

[0037] Preferably (Pd / Sunphos, Ligand L2, Ar=4-methylphenyl) take ethyl trifluoropyruvate (8.505 g, 50 mmol, 1eq) and place it in a baked reaction tube, and prepare the The catalyst was prepared as a catalyst solution, which was measured with a syringe (0.82 mL, concentration 8.2 g / L, 5 μmol, 0.01% eq) and added to the reaction system, stirred at room temperature for 30 minutes, and then the reaction system was placed in an ice-salt bath Cool down to -15~-20 o C. Add the prepared isobutene solution (364 g / L, solvent is toluene) into the reaction system to start the reaction. After the reaction is finished, post-treatment and distillation are carried out to obtain the pure product.

Embodiment 3

[0038] Example 3: Preparation of pure (R)-2-hydroxy-2-trifluoromethyl-4-methyl-4-pentenoic acid ethyl ester with a yield of 65% and an ee value of 88%.

[0039] (Pd / Sunphos, Ligand L3 , Ar=3,5-dimethylphenyl) weigh ethyl trifluoropyruvate (8.505 g, 50 mmol, 1 eq) and place it in a baked reaction tube, prepare the prepared catalyst as a catalyst solution, Measure (1.01 mL, concentration 10.1 g / L, 5 μmol, 0.01%eq) with a syringe and add to the reaction system, stir at room temperature for 30 minutes, then cool the reaction system to -15~- 20 o C. Add the prepared isobutene solution (364 g / L, solvent is toluene) into the reaction system to start the reaction. After the reaction is finished, post-treatment and distillation are carried out to obtain the pure product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| enantiomeric excess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com