A kind of selective nickel-based hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst, catalyst technology, applied in the direction of selective hydrorefining, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem that diolefins do not have hydrogenation selectivity and the like , to achieve the effect of good hydrogenation activity, strong hydrogenation stability and thermal stability, and strong poison ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Dissolve 20.7g of citric acid in water at 30°C, add 10.4g of lithium carbonate to prepare 60ml of aqueous solution, spray 300g of pseudo-boehmite alumina powder with this solution, knead while spraying, then add 80ml of water, 5ml of nitric acid ( 60% content) and 9.7g silica sol (containing 40% silica), continue to knead and extrude, dry at 120°C for 4 hours in the air, and roast at 980°C for 4 hours to obtain modified Al 2 o 3 carrier.

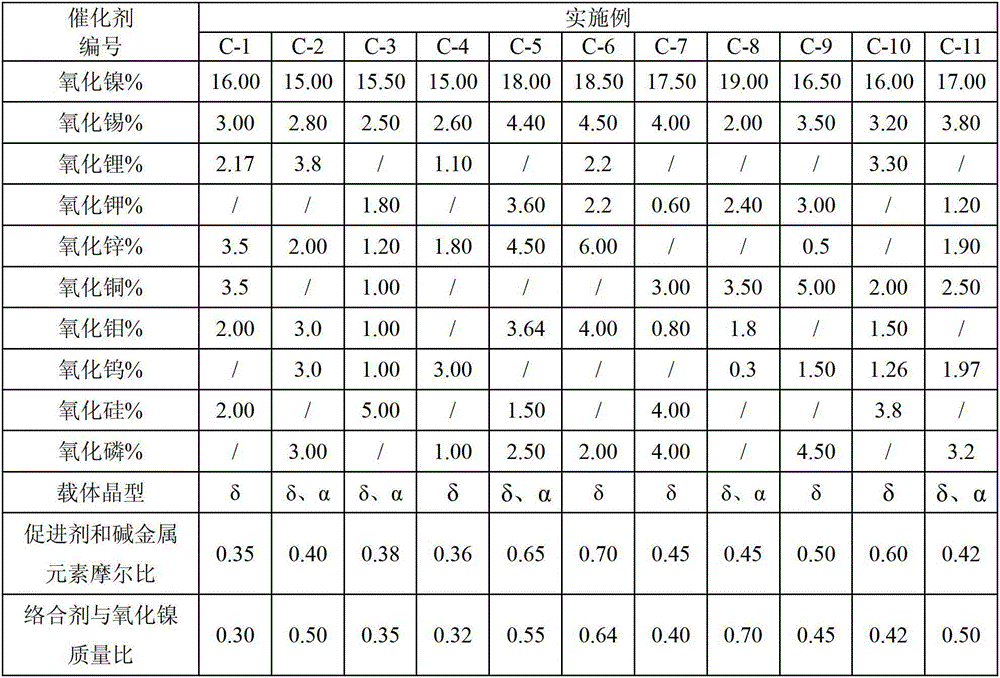

[0038] At 30°C, 86.4g of nickel nitrate, 7.2g of sodium stannate, 17.1g of zinc nitrate, 14.3g of copper nitrate, and 3.3g of ammonium molybdate were made into 90ml of aqueous solution, then 6.5g of tetraethylene glycol was added, and then immersed in 100g On the modified carrier, aged for 6 hours, dried at 120°C for 2 hours in air, and calcined at 350°C for 4 hours to prepare catalyst C-1. The composition of the catalyst is shown in Table 2.

Embodiment 2

[0044] Dissolve 42.6g of citric acid in water at 35°C, add 18.7g of lithium carbonate to prepare 60ml of aqueous solution, spray 300g of pseudo-boehmite alumina powder with this solution, knead while spraying, then add 80ml of water, 5ml of nitric acid ( Content 60%) and 9.7g phosphoric acid (content 85%), continue to knead and extrude, dry at 130°C for 2 hours in the air, and roast at 1050°C for 4 hours to obtain modified Al 2 o 3 carrier.

[0045] At 30°C, 80.7g of nickel nitrate, 6.6g of sodium stannate, 9.8g of zinc nitrate, 4.9g of ammonium molybdate, and 4.5g of ammonium tungstate were made into 90ml of aqueous solution, then 10.0g of triethylene glycol was added, and then immersed in 100g of modified carrier was aged for 6h, dried in air at 120°C for 3h, and calcined at 500°C for 6h to prepare catalyst C-2. The catalyst composition is shown in Table 2.

Embodiment 3

[0051] Dissolve 3.0g of citric acid and 1.3g of oxalic acid in water at 40°C, add 5.3g of potassium carbonate to prepare a 60ml aqueous solution, spray 300g of pseudo-boehmite alumina powder with this solution, knead while spraying, and then add 80ml of water and 5ml of nitric acid (content 60%) and 24.9g silica sol (containing 40% silica), continue to knead and extrude into strips, dry at 120°C for 3h in the air, and roast at 1100°C for 4h to obtain modified Al 2 o 3 carrier.

[0052] At 40°C, 79.4g of nickel nitrate, 5.7g of sodium stannate, 5.6g of zinc nitrate, 3.9g of copper nitrate, 1.5g of ammonium molybdate, and 1.4g of ammonium tungstate were prepared into 90ml of aqueous solution, and then 6.9g of triethylene glycol was added , and then impregnated on 100g of modified carrier, aged for 6h, dried in air at 120°C for 3h, and calcined at 550°C for 3h to prepare catalyst C-3. The catalyst composition is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com