Vacuum melting and slab casting method of titanium-aluminum alloy

A vacuum smelting and titanium-aluminum alloy technology, which is applied in the field of titanium-aluminum alloy slab processing, can solve problems such as composition segregation, lack of uniform structure, and metallurgical defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

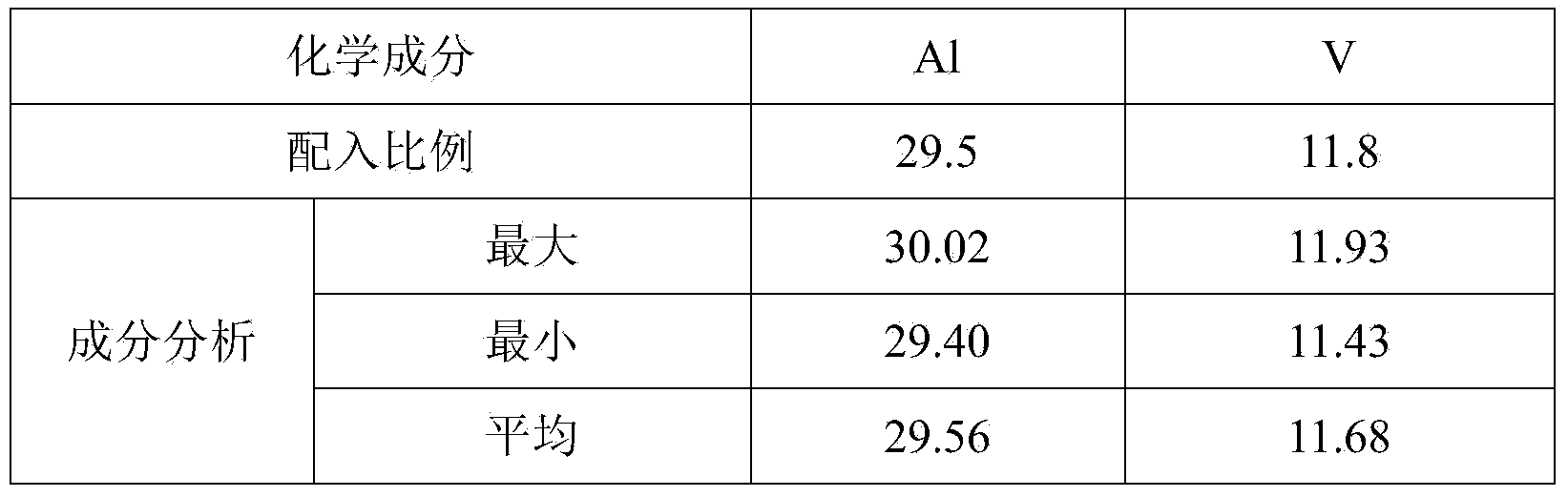

[0011] Process example: Titanium-aluminum alloy vacuum melting plus casting slab

[0012] 1. Preparation of electrodes:

[0013] 1) Raw material: Grade 0 titanium sponge (particle size 12.5~25.4mm)

[0014] Aluminum vanadium alloy (58% vanadium content)

[0015] Aluminum beans: (particle diameter less than 10mm)

[0016] The hydraulic press presses the approximate circular electrode block, with a density of more than 3.0 g / cm3. After pressing, use argon shielded plasma welding to weld the electrode block into an electrode to be melted.

[0017] 2. One-time smelting by vacuum self-consumption

[0018] Melting voltage: 25-37 volts

[0019] Current: 40-70 amps / square centimeter

[0020] Melting vacuum degree: 0.4~3 Pascal

[0021] One ingot casting:

[0022] The crucible is made of special metal composite material and is cooled by external water.

[0023] 3. Secondary smelting of vacuum shell

[0024] The primary ingot is melted twice in a 250kg vacuum shell furnace, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com