Explosive welding method for hard and brittle materials

A technology of explosive welding of hard and brittle materials, applied in the field of material processing, can solve the problems of only a few tens of bonding strengths, impossibility of industrial production, low bonding rate and bonding strength, etc., to reduce the possibility of cracking and make processing simple and convenient , The performance is uniform and consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 adopts the method of the present invention to prepare tungsten steel metal clad plate

[0034] The tungsten steel metal clad plate in this embodiment is composed of the following materials: the thickness of the tungsten plate is 2mm, the thickness of the steel plate is 30mm, the tungsten plate is used as the double plate, and the steel plate is used as the substrate.

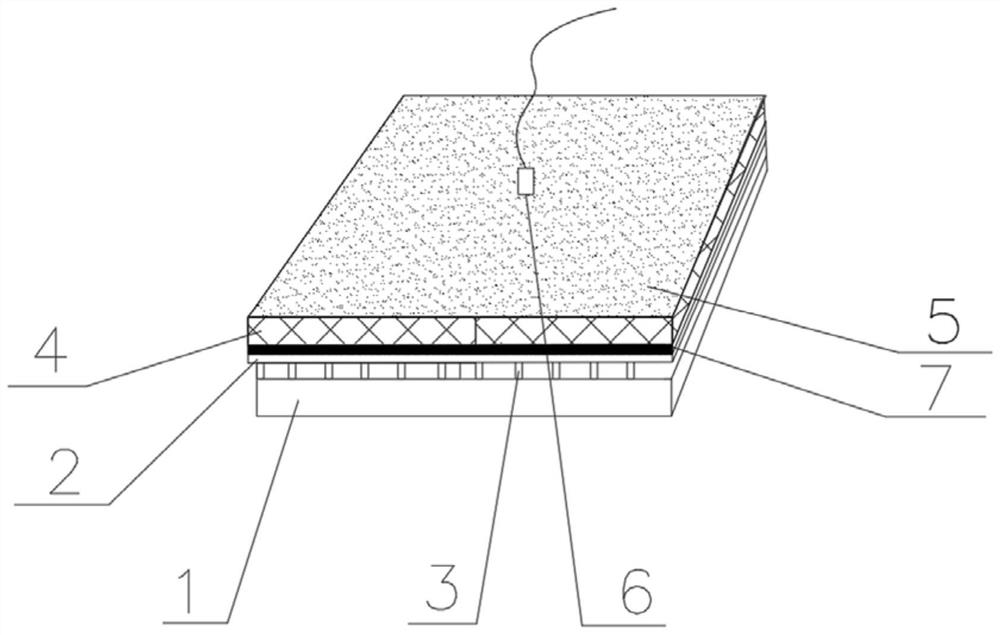

[0035] The specific steps of the preparation method are as follows (the use state diagram before the explosive welding structure is composited is as follows figure 1 shown):

[0036] Step 1. Select the base plate 1 and the doubler plate 2 according to the material of the explosive composite plate to be prepared, then lay the doubler plate 2 on the top of the base plate 1, and evenly arrange a plurality of support columns 3 between the base plate 1 and the doubler plate 2, so that The gap between the substrate 1 and the compound plate 2 is 6mm; the substrate 1 is a common carbon steel plate w...

Embodiment 2

[0041] Embodiment 2 adopts the method of the present invention to prepare molybdenum steel metal clad plate

[0042] The molybdenum-steel metal clad plate in this embodiment is composed of the following materials: the thickness of the molybdenum plate is 3mm, the thickness of the steel plate is 30mm, the molybdenum plate is used as the cladding plate, and the steel plate is used as the base plate.

[0043] The specific steps of the preparation method are as follows:

[0044] Step 1. Select the base plate and the doubler plate according to the material of the explosive composite plate to be prepared, then lay the doubler plate on the top of the base plate, and evenly arrange a number of support columns between the base plate and the doubler plate, so that the gap between the base plate and the doubler plate is 6mm; the base plate is a common carbon steel plate with a size of 1000mm×1000mm×50mm, and the doubler plate is a molybdenum plate with a size of 1040mm×1040mm×2mm; a plur...

Embodiment 3

[0049] Embodiment 3 adopts the method of the present invention to prepare titanium alloy steel metal clad plate

[0050] The titanium-steel metal clad plate in this embodiment is composed of the following materials: a titanium alloy with a thickness of 8mm, a steel plate with a thickness of 50mm, the titanium plate is used as the double plate, and the steel plate is used as the base plate.

[0051] The specific steps of the preparation method are as follows:

[0052] Step 1. Select the base plate and the doubler plate according to the material of the explosive composite plate to be prepared, then lay the doubler plate on the top of the base plate, and evenly arrange a plurality of support columns between the base plate and the doubler plate, so that the gap between the base plate and the doubler plate is 12mm; the base plate is a plain carbon steel plate with a size of 1000mm×1000mm×50mm, and the doubler plate is a titanium plate with a size of 1040mm×1040mm×2mm; a plurality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com