Explosion welding technique for combining multiple layers of brittle metal foils to become flat plate

A brittle metal, explosive welding technology, applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve the problem of material fragmentation and achieve the effect of manufacturing a wide range of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

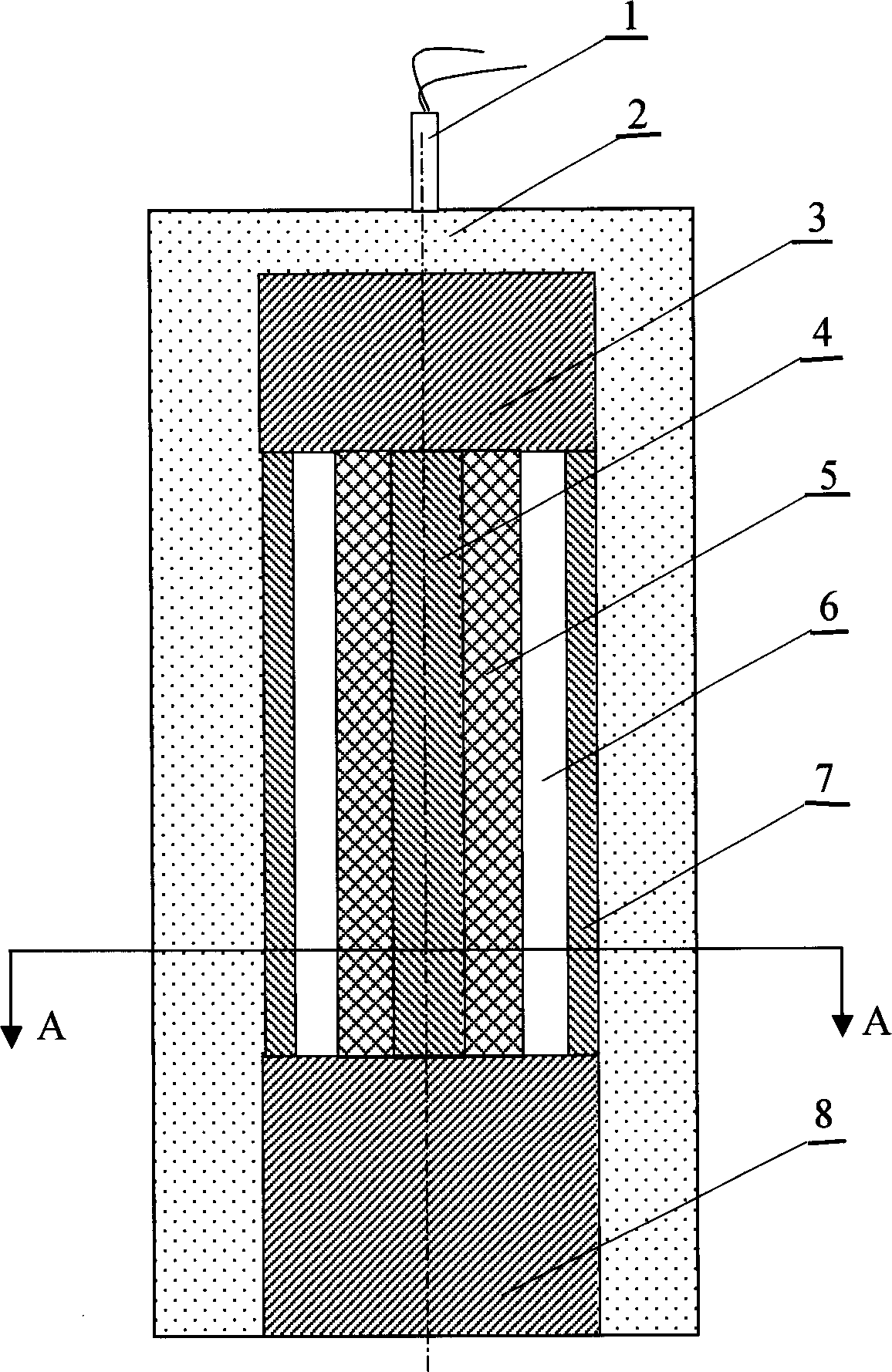

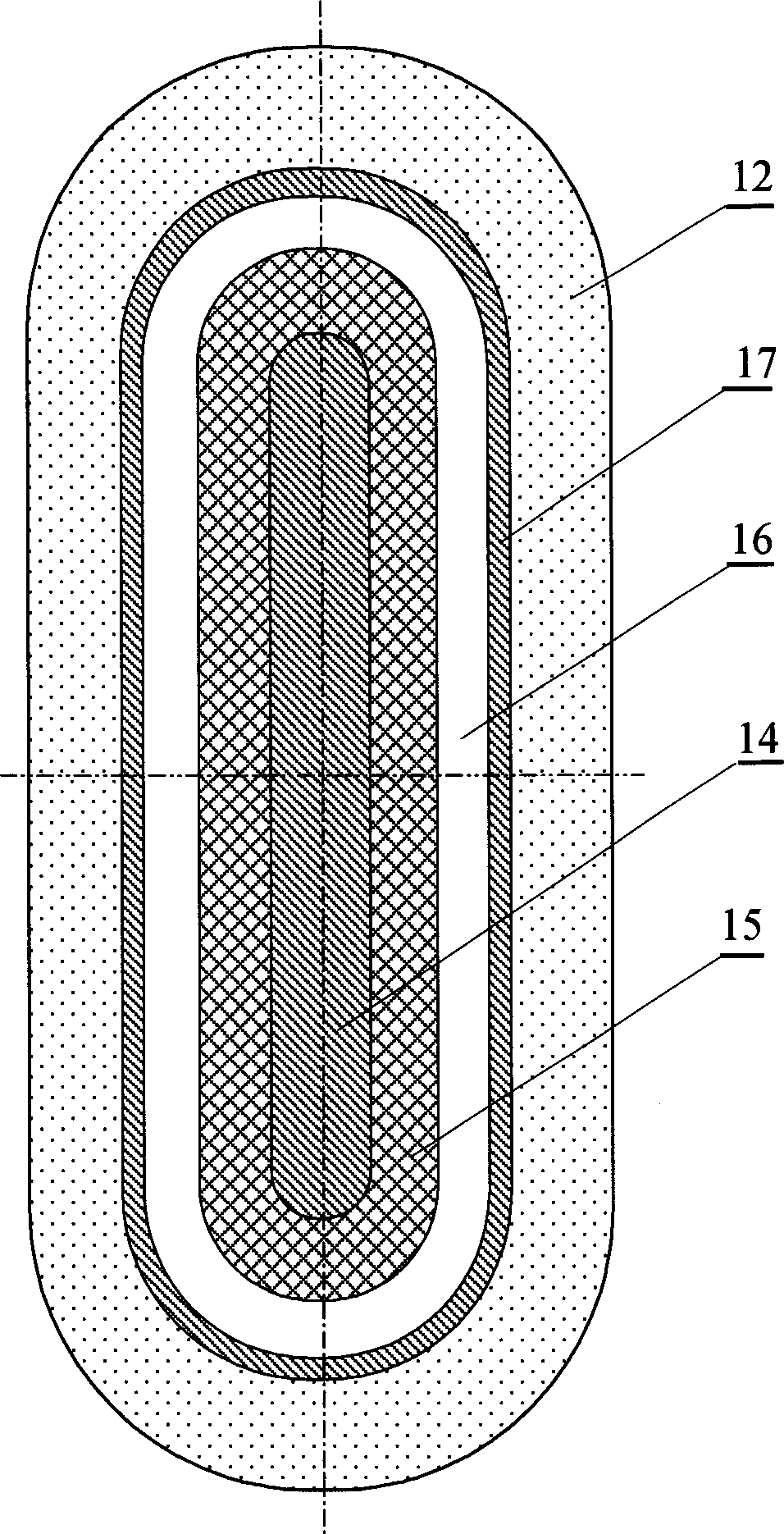

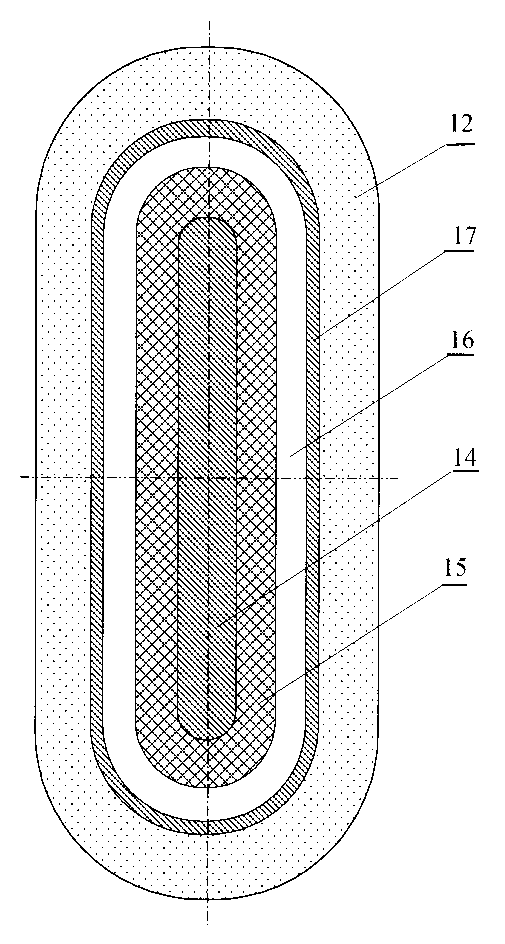

Embodiment 1

[0017] Using Fe with a thickness of about 25 μm and a bandwidth of 100 mm 78 B 13 Si 9 Iron-based amorphous alloy foil, elongation less than 2%, microhardness Hv=910Kg / m 2 . Roll the amorphous alloy foil tightly on the 100×60×10mm core board (4) coated with a solder stop layer, a total of 120 layers, the rolled multi-layer amorphous alloy foil (5) and the core board (4) The total thickness is about 20 mm, the width is 65 mm, and the average gap between the amorphous foils is 10 μm. The doubler board material is ordinary steel with a thickness of 1.75mm. The flat tube (7) made of it is 75mm wide and 29.5mm high. The outer diameter of the semicircular section is Φ29.5mm. The gap (6) is about 3-3.25mm. The thickness of the outer cloth explosive (2) is 37mm, and the detonation velocity is 4800m·s -1 . After the implementation of explosive welding, the semicircular parts at both ends and the edge were cut off by EDM, and two composite plates of 80×50×4.8mm were obtained, in ...

Embodiment 2

[0019] Except that talc powder is coated on the inner surface of the doubler plate flat tube (7) as an anti-sticking layer, the same conditions as in Example 1 are adopted, after explosive welding and electric spark cutting, two pieces of 80 × 50 × 3mm are obtained. Fe 78 B 13 Si 9 The amorphous block blank is reduced to a thickness of 2.2 mm after being ground by a grinder. X-ray diffraction confirms that it still remains amorphous and has no macroscopic cracks in appearance.

Embodiment 3

[0021] Using the same conditions as in Example 1, the inner surface of the flat tube (7) was coated with a talcum powder anti-adhesive layer, and a layer of 45 μm pure aluminum foil was added every 20 layers of amorphous alloy foil. After explosive welding and electric spark cutting, two pieces of 80×50×3.3mm Fe 78 B 13 Si 9 Composite material of amorphous alloy and aluminum foil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com