Explosion welding technique for combining multiple layers of brittle metal foils to become flat plate

A brittle metal, explosive welding technology, applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve the problem of material fragmentation and achieve the effect of manufacturing a wide range of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

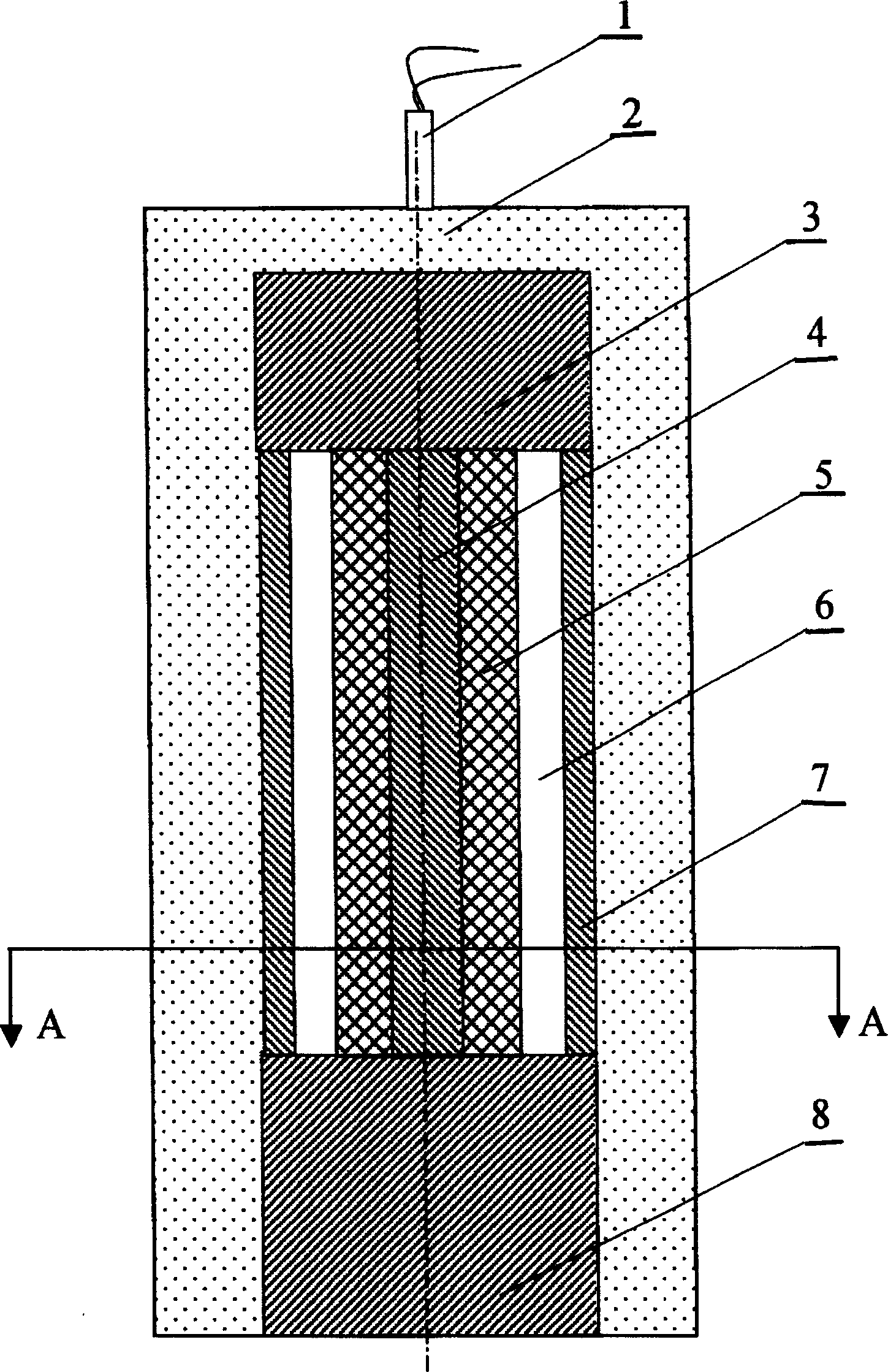

Embodiment 1

[0018] Using Fe with a thickness of about 25 μm and a bandwidth of 100 mm 78 B 13 Si 9 Iron-based amorphous alloy foil, elongation less than 2%, microhardness Hv=910Kg / mm 2 . Roll the amorphous alloy foil tightly on the core board 4 coated with a solder stop layer of 100×60×10 mm, a total of 120 layers, and the total thickness of the rolled multi-layer amorphous alloy foil 5 and the core board 4 is about 20mm , with a width of 65 mm and an average gap between amorphous foils of 10 μm. The doubler plate material is ordinary steel with a thickness of 1.75mm. The flat tube 7 is 75mm wide and 29.5mm high. The outer diameter of the semicircle section is Φ29.5mm. ~3.25mm. The thickness of the outer cloth explosive 2 is 37mm, and the detonation velocity is 4800m·s -1 . After the implementation of explosive welding, the semicircular parts at both ends and the edge were cut off by EDM, and two composite plates of 80×50×4.8mm were obtained, in which the consolidated Fe 78 B 13 ...

Embodiment 2

[0020] Except that talcum powder is coated on the inner surface of the doubler plate flat tube 7 as an anti-sticking layer, the same conditions as in Example 1 are adopted, after explosive welding and electric spark cutting, two pieces of 80×50×3mm Fe 78 B 13 Si 9 The amorphous block blank is reduced to a thickness of 2.2 mm after being ground by a grinder. X-ray diffraction confirms that it still remains amorphous and has no macroscopic cracks in appearance.

Embodiment 3

[0022] Using the same conditions as in Example 1, the inner surface of the flat tube 7 was coated with a talcum powder anti-adhesive layer, and a layer of 45 μm pure aluminum foil was added every 20 layers of amorphous alloy foil. After explosive welding and electric spark cutting, two pieces of 80×50×3.3mm Fe 78 B 13 Si 9 Composite material of amorphous alloy and aluminum foil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com