Antistatic BOPP film and composite construction process preparation technology

A composite structure and preparation process technology, applied in the field of plastic films, can solve problems such as inability to eliminate static electricity, and achieve the effects of improving anti-static performance, reducing surface resistivity, and reducing surface resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

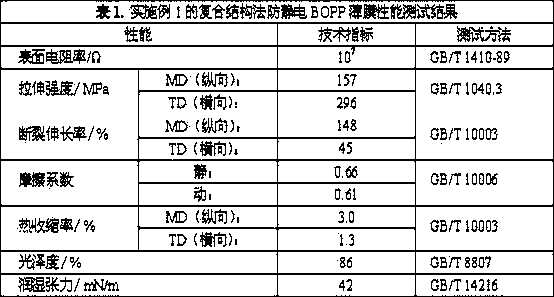

Embodiment 1

[0023] A composite structure method antistatic BOPP film with a multi-level, multi-scale and multi-phase topological composite structure system. This BOPP film is composed of an antistatic upper surface layer, a core layer and a heat-sealed lower surface layer through co-extrusion. The anti-static upper surface layer is prepared by an anti-static process; using the polarization characteristics of self-polarized polypropylene, the anti-static agent is fully dispersed and combined in the upper surface film matrix to improve its ability to migrate to the surface, and self-polarized polypropylene The polarization characteristics of the film further reduce the surface resistivity of the anti-static upper surface layer, thereby significantly improving the anti-static function of the film. The core layer and the heat-sealed lower layer are made of ordinary polypropylene materials to retain the original properties of the film, including mechanical and mechanical properties, but also to...

Embodiment 2

[0036] An antistatic BOPP film with a composite structure method has the same multi-level, multi-scale, and multi-phase topological composite structure system as in Example 1.

[0037] The preparation method is as follows:

[0038] (1) Preparation of antistatic masterbatch: the self-polarized polypropylene with a mass fraction of 15%, general polypropylene with a mass fraction of 70%, and an antistatic agent with a mass fraction of 15% are combined on a twin-screw extruder. Mix and extrude to prepare anti-static masterbatch. The processing temperature is 180~250℃.

[0039] (2) Preparation of anti-static upper surface layer material: when preparing the film by co-extrusion, the anti-static masterbatch with a mass fraction of 10%, general polypropylene and other additives are blended and compounded on the auxiliary extruder for preparing the upper surface layer , To form the anti-static upper surface material, and then the molten material enters the co-extrusion die and co-extrudes t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com